1. Basic information

Lubricants are being developed with high lubricity to reduce the compression tonnage and release pressure and to compensate for the lack of compressibility of the base powder. However, these lubricants have low melting points and tend to agglomerate during the compounding process, especially when used in hot weather, which limits their use on a large scale. All the major raw material companies in the world have developed their own high lubricants, but none of them can overcome this deficiency.

The design principle is to take the low melting point and high lubricity material as the basic particles and combine the high melting point and high lubricity material coating on the periphery.

Considering the fluidity of mixed powder, TRUER Company repeatedly optimized the coating thickness to ensure no damage during mixing process.

At the same time, in order to ensure the clean appearance of sintering, all components of the lubricant are all organic substances that can be completely decomposed. No sintering residue.

2.Test Content

Powder Preparation

Powder Testing

Pressing Test

Sintered Appearance

Microanalysis

3. Analysis of results

Testing lubricants

SUW4000: Conventional wax-based lubricant.

Lube A: Modified wax-based lubricant.

Lube B: Composite full lubricant.

Mixing Powder Preparation

Formulation: LAP100.29S + 0.3% Graphite + 1.4% Cu-200 + 0.7% Lubricant

Iron powder is a free cutting powder of Laiwu Steel

Mixing: 25kg double cone mixer, mix 20kg powder, mixing time 50 minutes.

Pressing and sintering

Target product: compressor piston, weight 28 g, pressing density 6.8 g/cm3.

Type of press: Huizhong mechanical press, a maximum tonnage of how many tons.

Sintering: pusher road sintering, nitrogen-hydrogen mixed atmosphere, sintering temperature 1120℃, sintering time 30 minutes.

Powder performance test: 1120℃, sintering time 30 minutes.

The mixed powder rests for 10 days.

Storage environment

General plant with about 70% humidity and a temperature of about 32°C in steel drums.

| AD | FLOW | |

| Lube A | 3.13 | 33.5 |

| Lube B | 3.22 | 35.6 |

| SUW 4000 | 3.23 | 33.1 |

According to the test results of powder performance, the flow rate of conventional wax-based lubricant and modified wax-based lubricant is close to each other, and the modified loose ratio is slightly lower; for compound lubricant, the loose ratio is close to each other and the flow rate is slightly lower.

Pressing effect

Press the same density, control the weight and height of the product, test the maximum pressing pressure, and average the pressures of 10 products after the pressing has been stabilized, as follows.

| Lube A | Lube B | SUW 4000 | |

| suppressing pressure | 17.6 | 16.4 | 19.2 |

| suppressing pressure | Bright | bright | bright |

There is a significant reduction in the pressing pressure compared to the modified version of the conventional lubricant, with a pressure reduction of 1.6 tons, or about 8%. In the case of complex lubricants, the pressing pressure is reduced by 2.8 tons, or about 15%. Forming pressure is a combination of particle rearrangement, mold wall lubrication, and interparticle lubrication, and a 15% drop in press tonnage is a welcome effect.

sintering

Sintered products are primarily used to evaluate the appearance of the product after sintering.

As can be seen from the sintered appearance, all three lubricants are thoroughly broken down with no residue and are clean lubricants.

Metallurgical analysis:

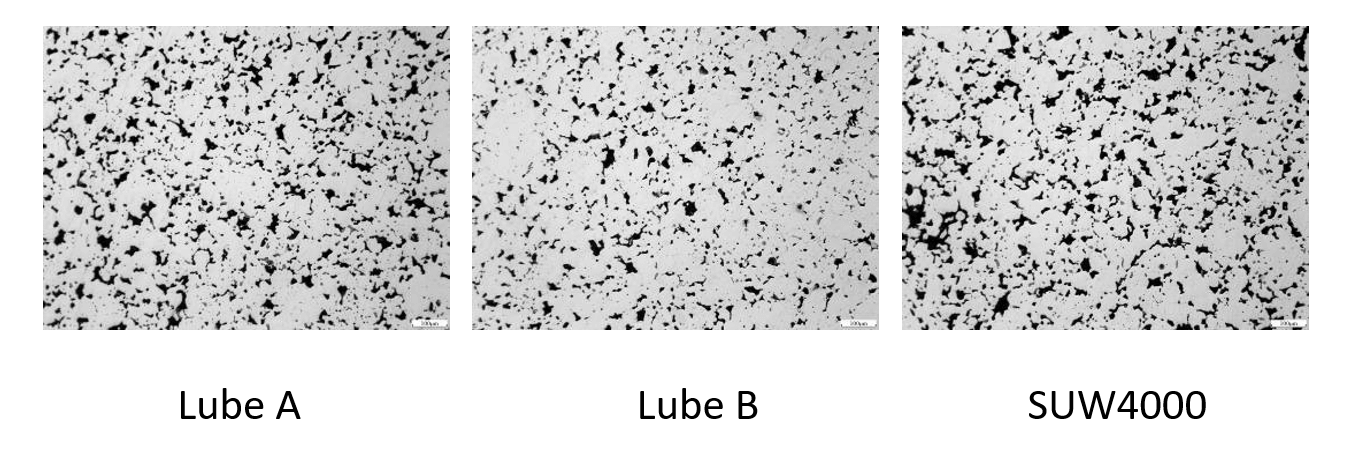

Pre-corrosion photographs:

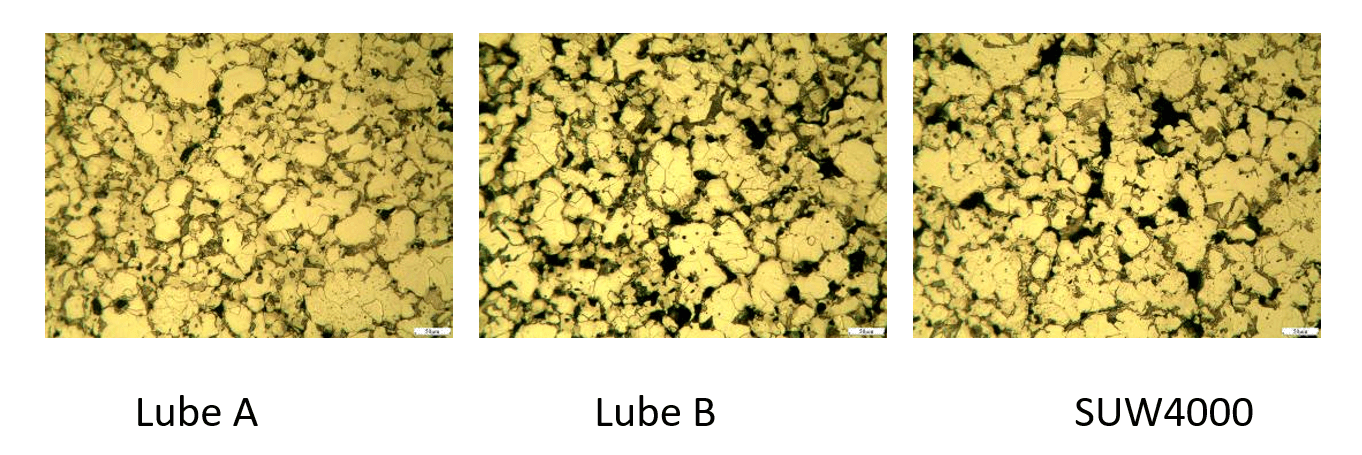

Post-corrosion photos:

No lubricant agglomerated pores were seen in the pre-corrosion photos, and no abnormalities were seen in the post-corrosion tissue.

4. Conclusion

The metallographic analysis led to the following conclusions.

1. All three lubricants are suitable for conventional double cone mixing from the point of view of loosening and flowability of mixed powder.

2. From the molding process, the two new lubricants have reduced the pressing tonnage, especially the compound lubricant.

3. After sintering, the parts of all three lubricants are spotless, which means they are clean lubricants.

4.Metallographic analysis of the sintered parts revealed no agglomerated pores, indicating no agglomeration.

5. evaluation comments

Lube B is an all-in-one lubricant with excellent overall performance.

According to its loose ratio flow rate and lubrication effect, it is reasonable to recommend 0.5% as the dosage to maximize the overall efficiency.

P.S. The official grade of LUBE-A is SUW-5000B, LUBE-B is SUW-8000.