Stainless Steel Powder

Stainless steel generally contains chromium content greater than 12%, which has good weldability& chemical stability, and excellent corrosion resistance to air, water, salt aqueous solutions, and other media. It is widely used in construction, transportation, energy, packaging, household appliances, and industrial fields.

Stainless steel powders include 316L, 304L, 17-4PH, 15-5PH, 410L, 420, 430L, 440C, 1.4091, 904L & CX. The grades can be categorized in four groups: ferritic, austenitic, martensitic and precipitation hardening types. Ferritic and martensitic type have a very attractive cost/performance ratio but a somewhat lower corrosion resistance comparable with austenitic type. 17-4PH and 316L powder are two kinds of most commonly used stainless steel powders.

17-4PHis one kind of low-carbon, high chromium precipitation hardening stainless steel with good corrosion resistance, improved hardness and strength by adding strengthening elements such as Cu& Nb to precipitate second phase strengthening particles such as ε-Cu & NbC during the aging process.

316Lstainless steel is an austenitic chromium-nickel stainless steel that contains between 2% and 3% molybdenum. The molybdenum content increases corrosion resistance, improves resistance to pitting in chloride ion solutions, and increases strength at high temperatures. Type 316L grade stainless steel is particularly effective in acidic environments. Common uses for type 316 stainless steel powder include in the construction of exhaust manifolds, furnace parts, heat exchangers, jet engine parts, pharmaceutical and photographic equipment, valve and pump parts, chemical processing equipment, tanks, and evaporators.

Our particlesize range normally can be 5-200um, including common range 0-22um, 15-53um, 20-65um, 53-106um and 53-150um. Other particle size distribution also can be provided per customer specification.

Welcome to inquire about prices and technical specifications (including powder morphology and particle size etc.).

| CHEMICAL COMPOSITION (wt%) | ||||||||

| Grade | Fe | C | Cr | Ni | Mo | Cu | Nb | Other |

| 316L | Bal | <0.03 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | / | / | / |

| 304L | Bal | <0.03 | 18.0-20.0 | 8.0-12.0 | / | / | / | / |

| 310S | Bal | <0.07 | 23.0-27.0 | 19.0-22.0 | / | / | / | / |

| 317L | Bal | <0.03 | 18.0-20.0 | 12.0-15.0 | 3.0-4.0 | / | / | / |

| 410L | Bal | <0.03 | 11.0-14.0 | / | / | / | / | / |

| 420 | Bal | 0.5-0.7 | 12.0-14.0 | / | / | / | / | / |

| 430L | Bal | <0.03 | 16.0-18.0 | / | / | / | / | / |

| 431 | Bal | <0.20 | 15.0-17.0 | 1.25-2.5 | / | / | / | / |

| 440C | Bal | 1.0-1.2 | 16.0-18.0 | / | 0.4-0.8 | / | / | / |

| 17-4PH | Bal | <0.07 | 15.0-17.5 | 3.0-5.0 | / | 3.0-5.0 | 0.15-0.45 | / |

| 15-5PH | Bal | <0.07 | 14.5-15.5 | 3.5-5.5 | / | 2.5-4.5 | 0.15-0.45 | / |

| TRC1.4 | Bal | 1.0-1.3 | 33.0-35.0 | 14.0-16.0 | 2.5-3.5 | W 0.6-1 | N 0.1-0.3 | / |

| 904L | Bal | <0.02 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | 1.0-2.0 | / | / |

| CX | Bal | / | 12.0-13.0 | 9.0-10.0 | 1.0-1.7 | / | / | Al 1.0-2.0 |

| 18Ni300 | Bal | <0.03 | / | 18.0-19.0 | 4.6-5.2 | / | / | Co 8.5-10.0 Ti 0.5-0.8 |

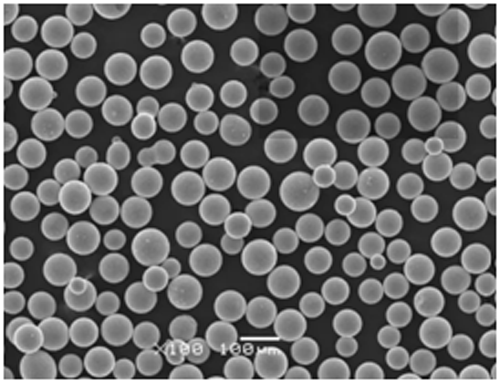

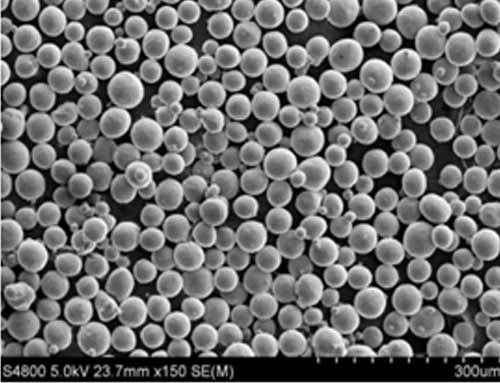

SEM Photos:

316L Powder by PREP

18Ni300 Powder by Gas Atomizing

If you have a special requirements , Just contact us and we will try to customize the powders for you