Powder Metallurgy Additive

Powder Metallurgy Additive FeP18

Color: Black

Shape: Powder

Brand Name: Truer

Product name: FeP18

Application: Metallurgy Additive

Place of Origin: Shanghai, China

Category: powder metallurgy additive

Price: For a more detailed quote, please send us an inquiry.

Product Features

FeP18 can be used in the manufacture of requirements for high hardness, high strength, good plasticity, good toughness, late plastic is not brittle fracture and airtight performance of good powder metallurgy products. Such as valve ducts, automotive ABS brake induction gear ring.

Characteristics

Promote sintering, accelerate the sintering process, and form eutectic reactions when Fe and FeP are sintered.

Fe-Fe3P-L(P), the liquid phase of P with the liquid phase in the gross under the action of suction brought around the iron particles, and soon diffused into the r-Fe, after cooling and melted in the α-Fe(P), so that the product is strengthened.

Characteristics

Activation sintering plays the role of solid solution strengthening, increasing the surface tension of the pores, so that the pores were a spherical state, play a role in filling closed pores, improve the density of products, improve product strength while improving product plasticity and toughness, can improve product airtightness performance.

The soft magnetic material can improve the product resistance, reduce the eddy current effect, and produce heat generation.

Fe-P iron-based products, in the P content of 0.45%, sintering strength can reach

300N/mm2 δ=3-5% ak=40J

δb=400N/mm2 ak=20-40J in the Fe-P-C system.

Product Description

Brand: FeP18

Quality standard: 20%≥≥17%

Appearance: silvery grey powder

Particle size: ≤10μm (average particle size)

Packing and Transportation

1. packaging: according to customer requirements.

2. transportation: non-dangerous goods, suitable for normal land, sea, and air transportation.

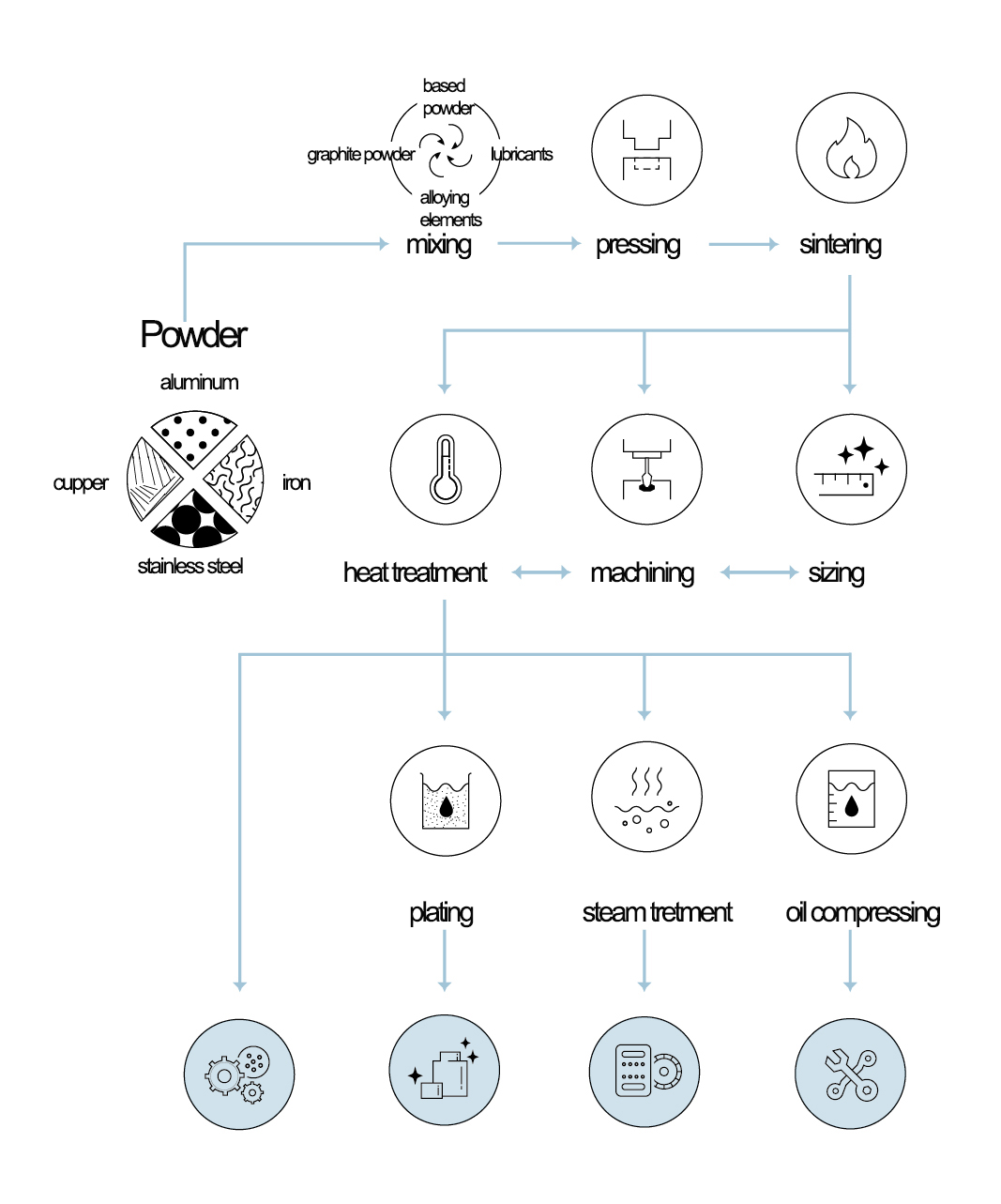

Production Process

About Truer

Shanghai Truer

Powder Metallurgy Additive Manufacturer

Shanghai Truer Industrial Development Co., Ltd. is an entity that integrates research and development, production, and sales. The excellent team is the cornerstone of our success, in 2007, we set up a research and development team, after in-depth research, Truer has set up two divisions, the Metallurgical Division and the Powder Metallurgy Additives Division.

TRUER Powder Metallurgy Additives Division is acknowledged to be one of the most professional additive suppliers in the Chinese powder metallurgy industry and committed to providing complete additive solutions to PM customers. TRUER has developed a variety of powder metallurgy, lubricants Lube-W, SUW-5000B, SUW-8000; cutting agent manganese sulfide, sulfur-free cutting agent SME-100, composite cutting agent TD-8; new soft magnetic additives QH-150; QHP-330 graphite TBC-400; TBC-1000 and so on. These raw materials are all supplied and customized by famous manufacturers

Production Process

TRUER Metallography Division TRUER Metallography is focusing on the production, development, and sales of metallographic equipment and consumables. TRUER has been committed to becoming the most professional supplier of metallographic equipment and consumables in China and the world. Through continuous exploration and development, we have successfully developed professional solutions for the analysis of different target materials and established a perfect product system, which covers metal, ceramics, electronics, plastics, and other major industries, and our high-quality products combined with perfect technical service are highly praised by the metallographic industry.

Solution Provider

Technical Certificates