Project Development Reports of Lubricants

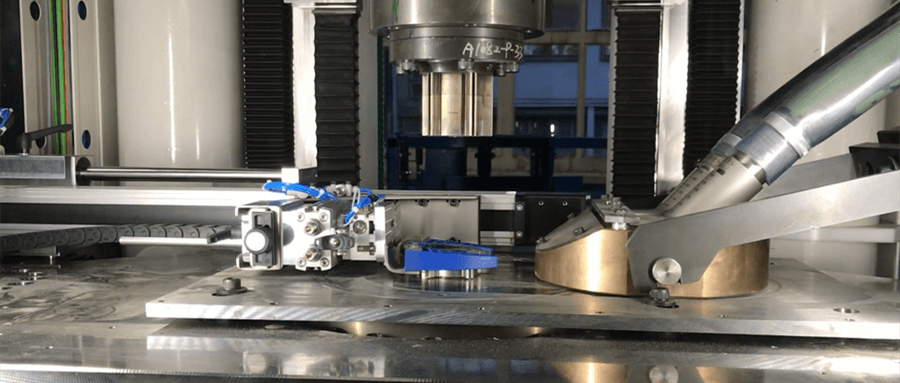

1. Basic information Lubricants are being developed with high lubricity to reduce the compression tonnage and release pressure and to compensate for the lack of compressibility of the base powder. However, these lubricants have low melting points and tend to agglomerate during the compounding process, especially when used in hot weather, which limits their use …

.jpg)

.jpg)

.jpg)

.jpg)