MoS2

Molybdenum Disulfide Lubricant Spray Features

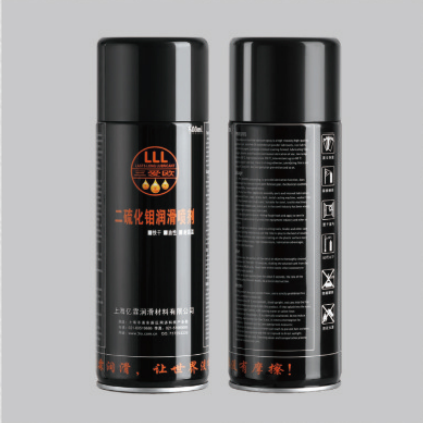

High-Temperature Molybdenum Disulfide Lubricant Spray, High Adhesion Molybdenum Disulfide Spray, Quick Dry Molybdenum Disulfide Lubricant Spray, Powerful Molybdenum Disulfide Lubricant Spray, Oily Molybdenum Disulfide Lubricant Spray.

Product Description:

Molybdenum disulfide spray is a spray lubricant made of resin and ultra-fine molybdenum disulfide as a base material, which can form a fast-drying film on the metal surface.

This molybdenum disulfide dry lubricant has a low coefficient of friction and can be sprayed to form a tough, heat-resistant, heavy-duty molybdenum disulfide lubricant film on the friction surface of metal parts, thus avoiding wear, ablation, and galling of parts.

This molybdenum disulfide lubricant is designed for lubrication of slides, studs, rails, connecting rods, and general machinery where maintenance is difficult, and for lubrication and anti-burning temperatures up to 450℃.

Product Features

Fast-drying, high-temperature resistance, anti-corrosion, large content, high purity, reasonable cost performance, easy to carry.

Use: It is suitable for spraying and lubricating the transmission parts of machinery, shipbuilding, steel, textile, forging, hardware, aviation, and other industries.

About Truer

Shanghai Truer

Powder Metallurgy Additive Manufacturer

Shanghai Truer Industrial Development Co., Ltd. is an entity that integrates research and development, production, and sales. The excellent team is the cornerstone of our success, in 2007, we set up a research and development team, after in-depth research, Truer has set up two divisions, the Metallurgical Division and the Powder Metallurgy Additives Division.

TRUER Powder Metallurgy Additives Division is acknowledged to be one of the most professional additive suppliers in the Chinese powder metallurgy industry and committed to providing complete additive solutions to PM customers. TRUER has developed a variety of powder metallurgy, lubricants Lube-W, SUW-5000B, SUW-8000; cutting agent manganese sulfide, sulfur-free cutting agent SME-100, composite cutting agent TD-8; new soft magnetic additives QH-150; QHP-330 graphite TBC-400; TBC-1000 and so on. These raw materials are all supplied and customized by famous manufacturers

Production Process

TRUER Metallography Division TRUER Metallography is focusing on the production, development, and sales of metallographic equipment and consumables. TRUER has been committed to becoming the most professional supplier of metallographic equipment and consumables in China and the world. Through continuous exploration and development, we have successfully developed professional solutions for the analysis of different target materials and established a perfect product system, which covers metal, ceramics, electronics, plastics, and other major industries, and our high-quality products combined with perfect technical service are highly praised by the metallographic industry.

Solution Provider

Technical Certificates