Powder Metallurgy Additive

Powder Metallurgy Cutting Agent MoS2

Color: Black

Shape: Powder

Brand Name: Truer

Product name: MoS2

Application: cutting agent

Place of Origin: Shanghai, China

Category: powder metallurgy cutting agent

Price: For a more detailed quote, please send us an inquiry.

Powder Metallurgy Cutting Agent MoS2 Features

Molybdenum disulfide is a special cutting agent for powder metallurgical parts. Due to characteristics such as dry machining and intermittent impact on the cutting edge, tool life is significantly increased when powder metallurgical parts are machined.

Molybdenum disulfide is uniquely engineered for solid-state lubrication and chip removal, which can extend tool life several times over.

Unique cutting performance

Molybdenum disulfide is uniquely engineered for solid-state lubrication and chip breaking capabilities to extend tool life several times over.

High-Temperature Stability

The product is chemically stable and resistant to high temperatures above 1600°C; the sintering process will not produce a chemical reaction with the sintering atmosphere and the surrounding matrix, thus ensuring effective chip capacity and preventing red hot wear of the tool.

Lubrication

The cutting agent has a unique laminate structure, which plays a solid lubricant role in reducing tool wear when turning or drilling.

Good Dispersion

The cutting agent is easily and evenly dispersed into the powder to ensure stable and consistent cutting results in all areas.

Dimensional Stability

The cutting agent has little effect on the dimensional variation of the sintered parts,

which helps to maintain the dimensional accuracy of the product.

Product Description

Fine granularity, black powder.

Product Specification

Control indicators Norm

Heat loss Max 0.8%

Particle size D90 < 10microns

Active ingredient content >99%

Loose density >2.5g/cm³

Storage Conditions

Humidity control and temperature control (humidity below 60%, the temperature below 40°C),

sealed after use to prevent open placement, used within six months.

Recommended for mixing

1. The weight percentage is between 0.4~0.5.

2. Weighing in a closed environment, suitable for double cone and V type mixer.

Packing and Transportation

1. packaging: 25kg net weight in plastic or iron drums, polyethylene moisture-proof inner bag.

2. transportation: non-dangerous goods, suitable for normal land, sea, and air transportation.

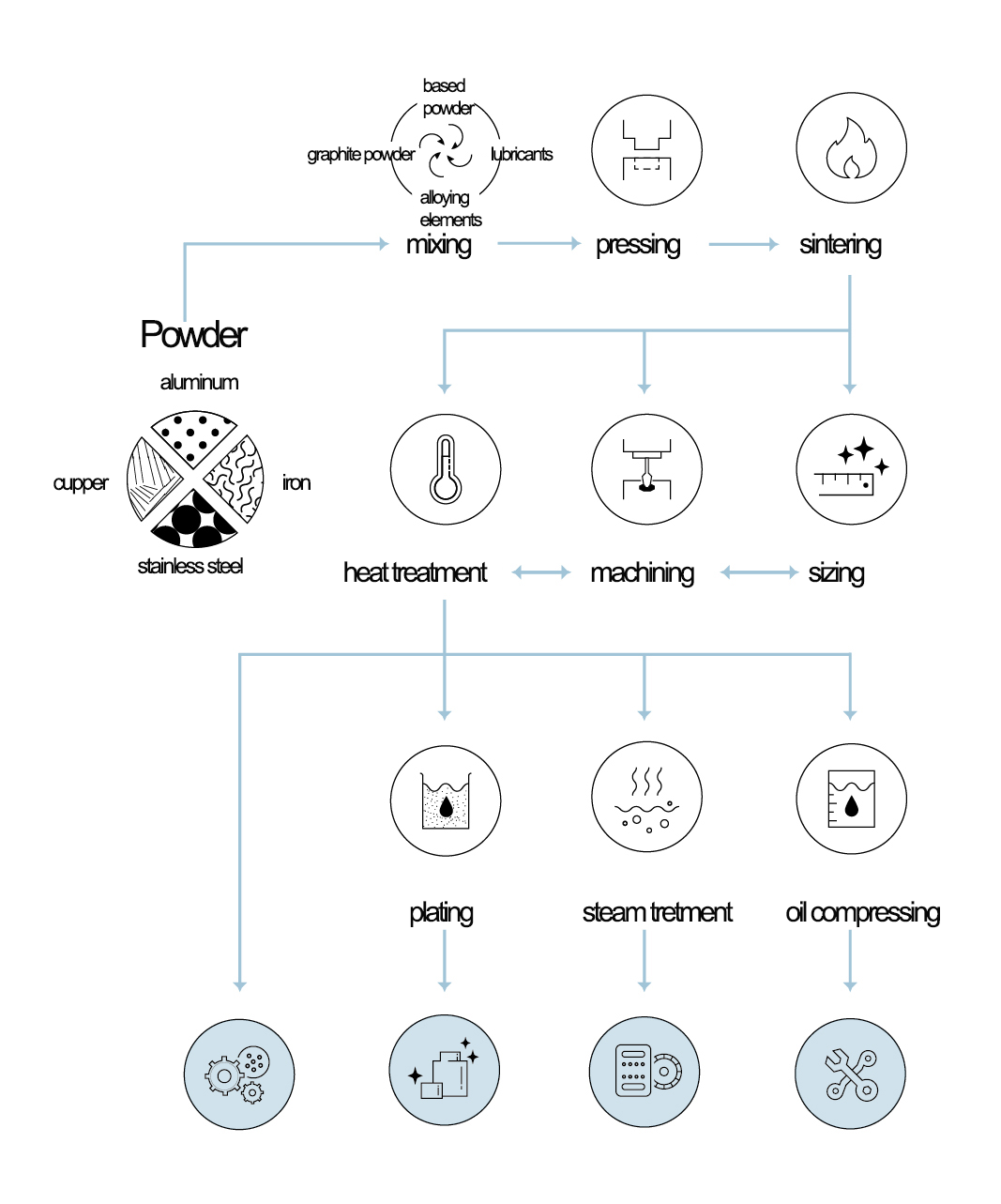

Production Process

About Truer

Shanghai Truer

Powder Metallurgy Additive Manufacturer

Shanghai Truer Industrial Development Co., Ltd. is an entity that integrates research and development, production, and sales. The excellent team is the cornerstone of our success, in 2007, we set up a research and development team, after in-depth research, Truer has set up two divisions, the Metallurgical Division and the Powder Metallurgy Additives Division.

TRUER Powder Metallurgy Additives Division is acknowledged to be one of the most professional additive suppliers in the Chinese powder metallurgy industry and committed to providing complete additive solutions to PM customers. TRUER has developed a variety of powder metallurgy, lubricants Lube-W, SUW-5000B, SUW-8000; cutting agent manganese sulfide, sulfur-free cutting agent SME-100, composite cutting agent TD-8; new soft magnetic additives QH-150; QHP-330 graphite TBC-400; TBC-1000 and so on. These raw materials are all supplied and customized by famous manufacturers

Production Process

TRUER Metallography Division TRUER Metallography is focusing on the production, development, and sales of metallographic equipment and consumables. TRUER has been committed to becoming the most professional supplier of metallographic equipment and consumables in China and the world. Through continuous exploration and development, we have successfully developed professional solutions for the analysis of different target materials and established a perfect product system, which covers metal, ceramics, electronics, plastics, and other major industries, and our high-quality products combined with perfect technical service are highly praised by the metallographic industry.

Solution Provider

Technical Certificates