Table of Contents

Toggle316 stainless steel powder is a specialized material with a range of uses in industries from aerospace to biomedical. This guide provides a detailed overview of 316 stainless steel powder including its composition, properties, applications, grades, specifications, pricing, pros/cons, and more.

Composition of 316 Stainless Steel Powder

The elemental composition of 316 stainless steel powder is:

| Element | Weight % |

|---|---|

| Iron (Fe) | Balance |

| Chromium (Cr) | 16-18% |

| Nickel (Ni) | 10-14% |

| Molybdenum (Mo) | 2-3% |

| Manganese (Mn) | <2% |

| Silicon (Si) | <1% |

| Phosphorus (P) | <0.045% |

| Sulfur (S) | <0.03% |

| Carbon (C) | <0.08% |

| Nitrogen (N) | <0.1% |

The high chromium and nickel content give 316 stainless its corrosion resistance. Molybdenum further enhances this property. The powder composition conforms to ASTM specifications for 316/316L grade with less than 0.08% carbon.

Overview of Properties and Characteristics

316 stainless steel powder offers an exceptional combination of properties:

| Property | Significance |

|---|---|

| Excellent corrosion resistance | Durability across range of chemical exposures |

| Outstanding strength | Can be sintered into high-strength parts |

| Bio-compatibility | Safe for use in medical devices/implants |

| Heat resistance | Retains strength and stability at high temperatures |

| Weldability | Easy to fuse components made from this powder |

| Machinability | Sintered/+dewaxed parts can be machined, drilled, tapped etc |

| Magnetism | Slightly magnetic due to nickel content |

These properties enable usage across a wide variety of applications and industries.

Applications and Uses of 316 Stainless Steel Powder

Some typical applications of 316 stainless steel powder include:

| Industry | Applications |

|---|---|

| Aerospace | Engine components, fittings, fasteners |

| Automotive | Valves, powdered metal parts |

| Chemical processing | Pumps, valves, tanks, pipes |

| Oil and gas | Wellheads, manifolds, downhole tools |

| Biomedical | Implants, surgical instruments, devices |

| 3D printing | Aerospace and automotive prototypes |

The corrosion resistance, strength and fabrication versatility make 316 stainless useful for demanding mechanical and structural applications. The biocompatibility enables medical uses as well.

Grades and Specifications of 316 Stainless Steel Powder

316 stainless steel powder is available in standard grades:

| Grade | ASTM Specification | Notes |

|---|---|---|

| 316 | ASTM A240, A276, A479 | Standard molybdenum-bearing grade |

| 316L | ASTM A240, A276, A479 | Low carbon variant, better welding |

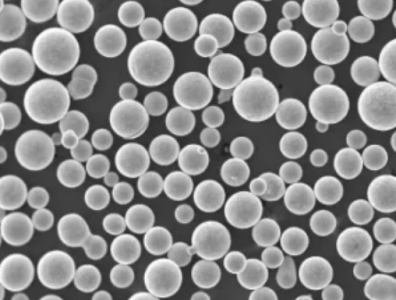

Popular size distributions:

| Mesh Range | Micron Range |

|---|---|

| -140+325 mesh | 44-104 microns |

| -325 mesh | <44 microns |

Both gas atomized and water atomized powders are common. Custom particle size distributions are available.

Pricing for 316 Stainless Steel Powder

| Distributor | Price Per Kg |

|---|---|

| Atlantic Equipment Engineers | $25 – $60 |

| Sandvik Osprey | $45 – $150 |

| Carpenter Powder Products | $40 – $100 |

| Höganäs | $30 – $80 |

| Kymera International | $35 – $90 |

Prices vary based on quantity ordered, size distribution, production method (gas vs. water atomized), supplier terms and location.

Pros vs Cons of 316 Stainless Steel Powder

| Pros | Cons |

|---|---|

| Excellent corrosion resistance | Expensive compared to carbon steel powder |

| High strength-to-weight ratio | Surface oxidation can occur during sintering |

| Very fine particles achievable | Needs good venting/atmosphere control when sintering |

| Custom alloy grades available | More difficult to compact into green parts vs. iron powder |

| Range of suppliers globally |

For critical applications where properties outweigh costs, 316 stainless powder delivers performance.

Frequently Asked Questions

Q: What particle size 316L powder is best for laser sintering AM?

A: Generally less than 45 microns (-325 mesh) is preferred, with D90 under 35 microns ideal.

Q: What is the typical tapped density for 316L stainless steel powder?

A: Between 4.0 to 4.8 g/cc based on the atomization method and particle size distribution.

Q: Is stainless steel powder reusable after sintering?

A: Yes, unused oversize powder can be salvaged and sieved for reuse if handled properly to avoid contamination.

Q: Does 316L powder require sintering in vacuum or inert atmospheres?

A: Vacuum or argon/nitrogen atmosphere is recommended during sintering to prevent surface oxidation effects.

Conclusion

With its corrosion resistance, strength, and fabrication versatility, 316/316L stainless steel powder is a material of choice across applications from biomedical implants to aerospace components. Understanding its detailed composition, properties, specifications and sintering considerations allows engineers to leverage the benefits of this material.