PBF-SEBM 3D Printing System

(SEBM-T200)

Target Groups:

The users who make the complex metal parts either in mass production or for prototypes with powder bed fusion technology – selective electron beam melting process.

Application:

Production of complex/customized metal parts, such as:

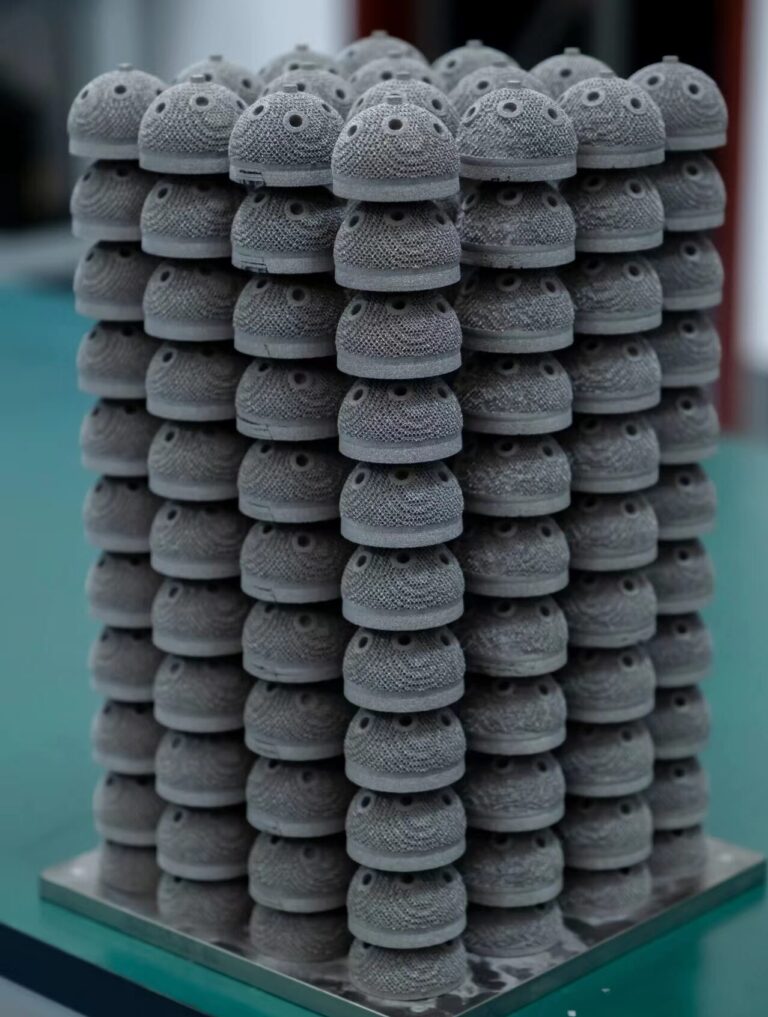

- Orthopedic implants

- TiAl blades / components

- Other metal components

Main Advantage

- Build size: 200mm x 200mm x 450mm

- The minimum beam diameter is less than 100μm

- Higher productivity thanks to higher energy density, lower reflectivity and strong penetration abilities to materials of electron beam and stacking capabilities;

- Better product performance thanks to forming in a controllable vacuum environment and higher pre-heating (up to 1100℃) during printing;

- Able to print the active and brittle metal powders (such as TiAl intermetallic compounds, pure copper, etc.) thanks to higher pre-heating temperature, higher energy density and vacuum environment, etc. (less internal stress and significantly reduces the risk of internal cracks);

- No extra heat treatment during post-treatment is needed for some materials thanks to higher temperature pre-heating and heat-remaining of the whole powder bed during printing;

- Easier post treatment thanks to the “fake sintering” capabilities during printing (no/less machining to remove the supports, normally, high-pressure compressed gas can be used to remove the excess powders which can be recycled);

- High cost performance ratio for some applications which has been proven, such as hip cups for the orthopedic industry and brackets for the aerospace industry.

Basic Principle

Powder Bed Selective Electron Beam Melting process (SEBM) is an additive manufacturing technology that uses high-energy electron beams as energy source to manufacture metal components in a high vacuum environment by melting metal powders layer by layer.

The process is: The electron beam quickly scans, pre-heats and melts the pre-laid spherical metal powders on the substrate plate according to the planned path. After completing a layer of scanning and melting, the substrate plate descends to a certain height and a new powder layer is laid. The electron beam scans and melts again according to the planned path, …, so the process is repeated layer by layer like this, finally, the metal parts are manufactured completely from 2D to 3D.

Technical Characteristics

- Electron beam as heat source with high energy density, high absorbtion and conversion rate to the printed materails with strong penetration ability to have deeper molten pool and denser formed parts

- Stacking production capabilities

- Pre-heating temperature up to 1100℃ or more

- Fake support (no/less supports are needed)

- Lower cost materials

- Forming in the vacuum environment

Main Technical Parameters

| Max. build size | 200mm×200mm×450 mm |

| Beam power | 6 kW |

| Electron accelerating voltage | 60 kV |

| Beam current | 0~100 mA |

| EB Filament life | >500 h |

| Cathode type | tungsten alloy |

| Min. beam diameter | ≤100 μm |

| Max. powder bed preheat temperature | 1100 ℃ |

| Ultimate vacuum in the printing chamber | 5×10-3 Pa |

| Build accuracy of components | ±0.2 mm |

| External dimension | 2400×1900×3600 mm3 |

| Machine weight | 4.5 t |

| CAD (interface) | STL |

| Control software | SEBM-ICS |

Printable Materials

- Titanium alloys (such as Ti6Al4V)

- Refractory metals (such as pure Tungsten, Tantalum, Niobium, Molybdenum, etc.)

- Titanium Aluminum alloys (Such as TiAl4822, etc.)

- Zirconium-Niobium alloys

- Nickel-base superalloys (Such as Inconel 718, Inconel 625, etc.)

- Other difficult-to-process materials.

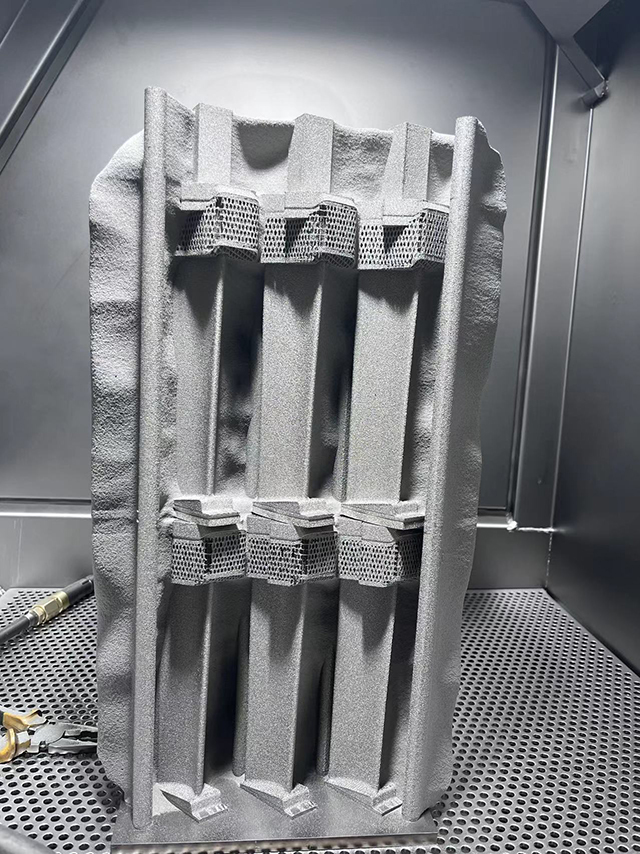

Examples

Tip Cups