Nickel-based Brazing Alloy Powder

Nickel-based brazing alloy powders (from BNi-1 to BNi-7 and NiCrPSi) are low-melting, free-flowing filler metal powders with excellent strength. It is typically used in brazing processes to join two or more metal components together. It can be used in various brazing techniques such as torch brazing, furnace brazing, and induction brazing.

BNi-1 and BNi-2 are Ni-Cr-B-Si-Fe alloy. BNi-2 has lower chromium content than BNi-1. Therefore, it has a lower melting point range. BNi-2 also is called as B-Ni82CrSiBFe, Ni620 or N99620.

BNi-3 and BNi-4 are Ni-B-Si alloy. BNi-4 has a higher melting point range than BNi-3 Powder.

BNi-5 is Ni-Cr-Si alloy. It is suitable for narrow and deep joints.

BNi-6 is Ni-P alloy powder, like all eutectic alloys, which has excellent flow characteristics when joints are narrow or deep. It is used to produce joints with high strength and good oxidation resistance even at elevated temperatures.

BNi-7 is Ni-Cr-P alloy. It widely used in the brazing of honeycomb structures, thin-walled tube assemblies, and nuclear applications where additions of boron are not permitted.

NiCrPSi powder with higher chromium which is used in brazing fields as bonding materials.

| CHEMICAL COMPOSITION (typical wt%) | ||||||

| Item | Ni | Cr | B | Si | Fe | P |

| BNi-1 | Bal | 14 | 3.2 | 4.5 | 4.5 | / |

| BNi-2 | Bal | 7 | 3.1 | 4.5 | 3 | / |

| BNi-3 | Bal | / | 3.2 | 4.5 | / | / |

| BNi-4 | Bal | / | 2.0 | 3.5 | / | / |

| BNi-5 | Bal | 19 | / | 10.1 | / | / |

| BNi-6 | Bal | / | / | / | / | 11 |

| BNi-7 | Bal | 14 | / | / | / | 10.1 |

| NiCrPSi | Bal | 29 | / | 4.0 | / | 6.0 |

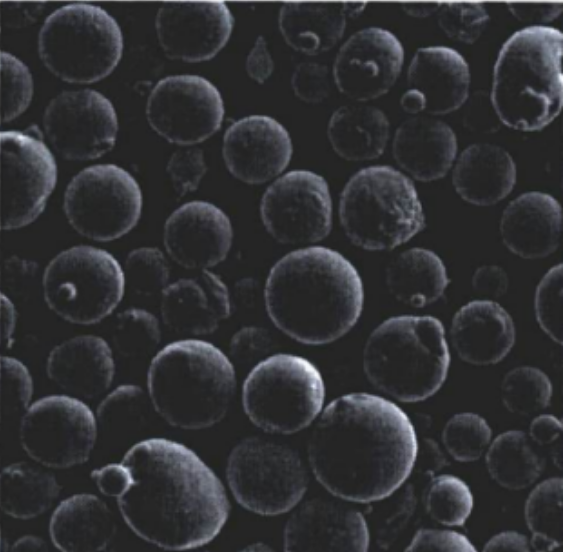

Gas Atomized NiCrPSi powder

Particle Size Distribution (PSD): 0-25, 15-45, 15-53, 45-105, 45-150um or sieved as required.

Shape: Spherical

Process: Gas atomized (GA)

Packing: 5kg, 10kg, 25kg or as required; plastic bottle/can.

Application: Brazing, bonding