Hastelloy Powders

Truer offers several different Hastelloy alloy powders, including but not limited to C-22, C-276, B, N and X powders. They are nickel based alloy powders with better corrosion resistance and high temperature resistance than stainless steels, used in additive manufacturing (3D printing, SLM/EBM/DLD), thermal spray, cladding and powder metallurgy processes.

Hastelloy C-22 (UNS N06022) and C-276 are used in severe corrosion environments in chemical processing industry and oil & gas fields.

Hastelloy X (UNS N06002) is one of the original nickel superalloys with excellent fabricability and weldability used in sintered metal parts and coating applications.

Hastelloy B alloys are nickel-molybdenum based alloys and used in extremely reducing and acidic environments, such as in sintered metal filters.

Hastelloy N alloy (UNS N10003) is a nickel-base alloy which has good oxidation resistance to hot fluoride salts in the temperature range of 704 to 871°C. It has good weldability and can be readily forged.

| CHEMICAL COMPOSITION (wt%) | ||||||||

| Item | Ni | Cr | Mo | Fe | W | Co | V | C |

| Hastelloy C-22 | Bal | 20.0-22.0 | 12.5-14.5 | 2.0-6.0 | 2.5-3.5 | / | / | 0.08 max |

| Hastelloy C-276 | Bal | 15.0-17.0 | 15.0-17.0 | 4.0-7.0 | 3.0-4.5 | / | 0.1-0.3 | 0.01 max |

| Hastelloy X | Bal | 20.5-23.0 | 8.0-10.0 | 17.0-20.0 | 0.2-1.0 | 0.5-2.5 | / | 0.05-0.15 |

| Hastelloy B | Bal | 1.0 max | 26.0-30.0 | 2.0 max | / | / | / | 0.02 max |

| Hastelloy N | Bal | 6.0-8.0 | 15.0-18.0 | 5.0 max | / | / | / | 0.04-0.08 |

Particle Size Distribution (PSD): 0-25,15-45, 15-53, 45-105, 45-150um or sieved as required.

Shape: Spherical

Process: Gas atomized (GA) or Plasma rotating electrode powder (PREP)

Packing: 5kg, 10kg, 25kg or as required; plastic bottle/can.

Application: additive manufacturing (3D printing, SLM/EBM/DLD), thermal spray, cladding and powder metallurgy processes.

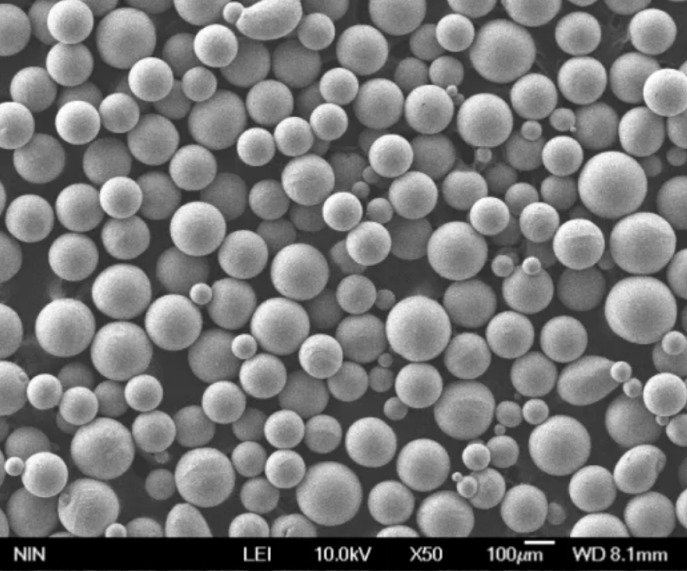

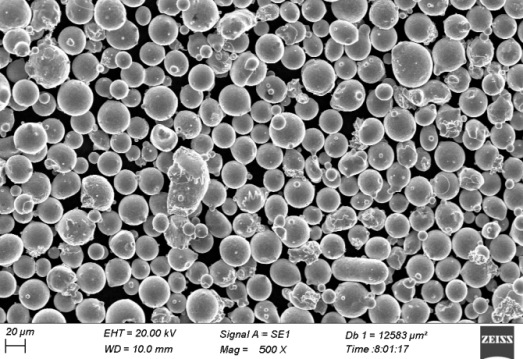

Morphology of Hastelloy X Powder:

GA