Table of Contents

ToggleIntroduction

Titanium alloys have revolutionized various industries due to their remarkable properties and wide-ranging applications. Among these, Titanio TC4 stands out as one of the most popular and versatile titanium alloys. This article explores the incredible properties, applications, and challenges associated with Titanio TC4, shedding light on why it has become a preferred material in diverse fields.

What is Titanio TC4?

Titanio TC4 is a titanium alloy known for its outstanding strength, low density, and exceptional corrosion resistance. It belongs to the Ti-6Al-4V alloy family, which is composed of titanium (Ti), aluminum (Al), and vanadium (V). The combination of these elements results in a material with remarkable mechanical properties and biocompatibility, making it suitable for numerous critical applications.

The Properties of Titanio TC4

High Strength-to-Weight Ratio

One of the most significant advantages of Titanio TC4 is its impressive strength-to-weight ratio. It boasts a tensile strength comparable to many steels but is about half the weight, making it ideal for weight-sensitive applications in aerospace, sports equipment, and more.

Corrosion Resistance

Titanio TC4 exhibits exceptional corrosion resistance, particularly in harsh environments where other materials may fail. This property is vital for applications in marine engineering, chemical processing, and medical implants, ensuring longevity and reliability.

Biocompatibility

The biocompatibility of Titanio TC4 makes it an ideal choice for medical implants, such as artificial joints and dental implants. It has a proven track record of successful use within the human body, as it minimizes the risk of allergic reactions and adverse effects.

Thermal Stability

Titanio TC4 retains its strength and mechanical properties at elevated temperatures, making it suitable for applications where exposure to high heat is inevitable, such as in aircraft engines and gas turbines.

Applications of Titanio TC4

Aerospace Industry

The aerospace industry relies heavily on Titanio TC4 due to its combination of high strength, lightweight, and resistance to fatigue. It is used in aircraft components, engine parts, and structural elements, contributing to enhanced performance and fuel efficiency.

Medical Implants

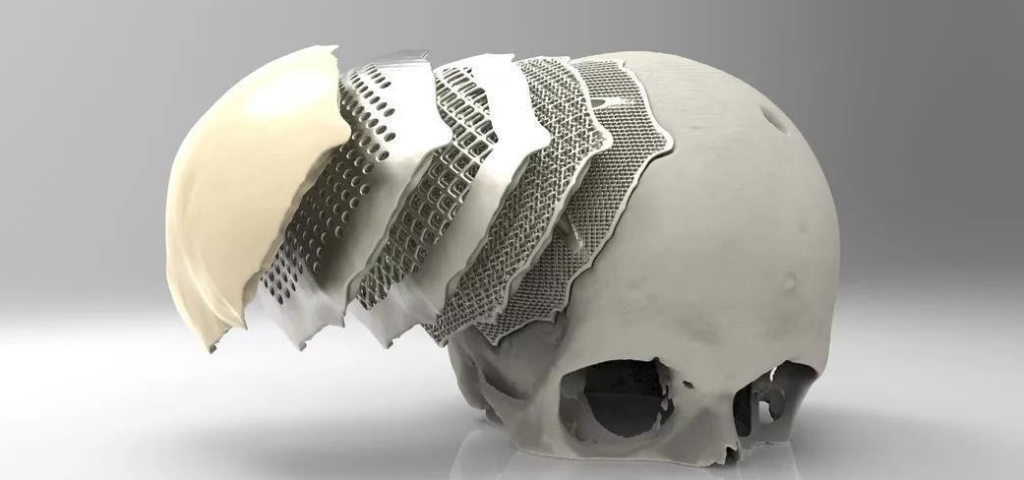

As mentioned earlier, Titanio TC4’s biocompatibility makes it an excellent choice for medical implants. Its use in orthopedic implants, dental fixtures, and prosthetics has transformed the healthcare sector.

Sporting Goods

In the sporting goods industry, Titanio TC4 is utilized to manufacture lightweight yet durable equipment. From golf clubs to bicycle frames, the alloy’s properties help athletes achieve better performance.

Marine Engineering

Titanio TC4’s resistance to corrosion and seawater makes it an ideal material for marine applications. It is commonly used in ship components, offshore structures, and underwater equipment.

Automotive Sector

The automotive industry benefits from Titanio TC4’s lightweight properties, contributing to improved fuel efficiency and reduced emissions. It finds application in exhaust systems, suspension components, and engine parts.

Processing and Manufacturing of Titanio TC4

Melting and Alloying

The production of Titanio TC4 involves melting titanium, aluminum, and vanadium together to form a homogenous alloy. The precise control of alloying elements is critical to achieving desired material properties.

Forming Techniques

Various forming techniques, such as forging and extrusion, are employed to shape Titanio TC4 into different products. These processes play a crucial role in determining the material’s mechanical properties.

Heat Treatment

Heat treatment is commonly applied to Titanio TC4 to optimize its mechanical characteristics. This process enhances the alloy’s strength and ductility, ensuring it meets specific application requirements.

Machining and Finishing

Machining Titanio TC4 requires special considerations due to its low thermal conductivity and tendency to work-harden. Advanced machining techniques and finishing processes are used to achieve precise and smooth surfaces.

Advantages of Titanio TC4 Over Other Materials

Titanium Alloys vs. Steel Alloys

Comparing titanium alloys like TC4 with traditional steel alloys, we see a significant advantage in terms of weight reduction without compromising strength. This advantage has made titanium alloys a preferred choice in aerospace and automotive applications.

Titanio TC4 vs. Titanio TC1

Titanio TC4 offers improved toughness and weldability compared to the earlier TC1 version. This advancement has expanded its applicability in various industries.

Comparison with Aluminum Alloys

Titanio TC4 outperforms aluminum alloys in terms of strength and corrosion resistance, making it a better choice for applications where lightweight and durability are crucial factors.

Challenges and Limitations of Using Titanio TC4

Cost

Titanium alloys, including Titanio TC4, can be expensive compared to other materials, impacting its adoption in cost-sensitive industries.

Complex Manufacturing

The production and processing of Titanio TC4 require specialized facilities and expertise, adding complexity to its manufacturing.

Galling

Galling, a form of wear in metal-to-metal contact, can occur in certain applications using Titanio TC4. Proper lubrication and surface treatments are needed to mitigate this issue.

Difficulty in Welding

Titanium alloys are known for their challenging weldability, and Titanio TC4 is no exception. Skilled welders and precise welding techniques are necessary to ensure the integrity of welded joints in Titanio TC4 components.

Future Prospects and Innovations

As technology advances and research in materials science continues, we can expect further innovations in the production and processing of Titanio TC4. Researchers are exploring new alloying elements and processing techniques to enhance its properties and reduce costs, making it more accessible to a broader range of industries. Additionally, advancements in additive manufacturing, such as 3D printing with Titanio TC4, hold promising potential for producing complex components with minimal material wastage.

Environmental Impact and Sustainability

Titanio TC4’s sustainability lies in its longevity and recyclability. Its corrosion resistance ensures a longer lifespan for components, reducing the need for frequent replacements. Furthermore, titanium alloys, including TC4, can be recycled, reducing the demand for new raw materials and minimizing environmental impact. The focus on environmentally friendly and sustainable materials in various industries is expected to drive further interest and adoption of Titanio TC4.

Conclusion

Titanio TC4 is a remarkable titanium alloy that has transformed numerous industries with its exceptional properties and versatility. From aerospace to medical implants, marine engineering to sporting goods, this alloy has proven its worth in demanding applications. Its high strength-to-weight ratio, corrosion resistance, biocompatibility, and thermal stability make it an attractive choice for various critical components. While challenges such as cost and complex manufacturing exist, ongoing research and innovation promise a brighter future for Titanio TC4.

FAQs

1. Is Titanio TC4 stronger than steel?

Yes, Titanio TC4 exhibits comparable strength to many steel alloys while being approximately half the weight, giving it a superior strength-to-weight ratio.

2. What are the main applications of Titanio TC4?

Titanio TC4 finds applications in the aerospace industry, medical implants, sporting goods, marine engineering, and the automotive sector.

3. How does Titanio TC4 compare to other titanium alloys?

Titanio TC4 offers improved toughness and weldability compared to earlier versions like Titanio TC1. It also outperforms aluminum alloys in terms of strength and corrosion resistance.

4. Are there any challenges in using Titanio TC4?

Some challenges include its relatively higher cost, complex manufacturing requirements, galling in certain applications, and difficulties in welding.

5. Is Titanio TC4 environmentally sustainable?

Yes, Titanio TC4’s longevity and recyclability contribute to its environmental sustainability, making it an attractive option for industries focused on reducing their environmental impact.