Table of Contents

Toggle1. Introduction

Metal Injection Molding (MiM) is an innovative manufacturing process that combines the versatility of plastic injection molding with the strength and durability of metals. MiM has gained significant popularity in various industries due to its ability to produce complex metal components with exceptional precision. This article delves into the world of MiM metals, exploring their advantages, manufacturing process, applications, and future trends.

2. What are MiM Metals?

MiM metals are metal components produced using the metal injection molding process. The process involves mixing fine metal powders with a binder material to create a feedstock that can be injected into a mold cavity. After injection molding, the binder is removed through a debinding process, and the remaining compacted metal part is sintered to achieve its final strength and density. The result is a fully dense metal component with intricate shapes and excellent mechanical properties.

3. Advantages of MiM Metals

3.1 High Precision

MiM metals offer exceptional dimensional accuracy and high precision. The injection molding process allows for the creation of complex geometries and intricate details that are difficult to achieve using traditional manufacturing methods. This level of precision makes MiM metals suitable for applications that demand tight tolerances and intricate designs.

3.2 Complex Geometries

MiM enables the production of complex metal components with intricate shapes, including thin walls, fine features, and undercuts. The ability to manufacture such complex geometries opens up new design possibilities for engineers and eliminates the need for secondary machining operations. MiM metals offer greater design freedom and facilitate the production of parts that were previously considered unachievable.

3.3 Material Selection

MiM metals can be produced from a wide range of materials, including stainless steels, tool steels, low-alloy steels, titanium alloys, and more. The versatility in material selection allows engineers to choose the optimal metal for their specific application requirements, ensuring the desired mechanical properties, corrosion resistance, and heat resistance.

4. MiM Metal Manufacturing Process

The manufacturing process of MiM metals consists of several key steps:

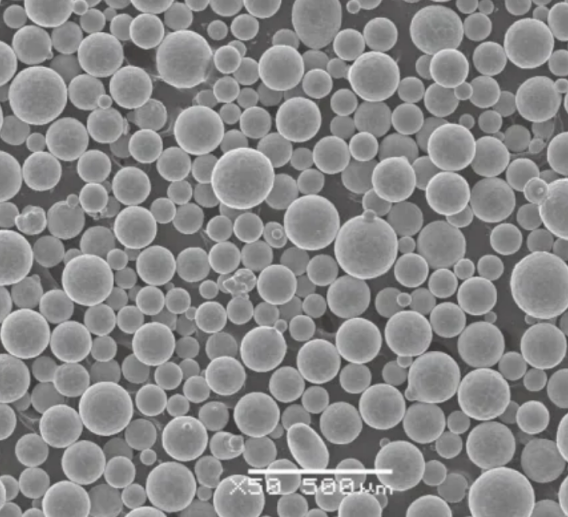

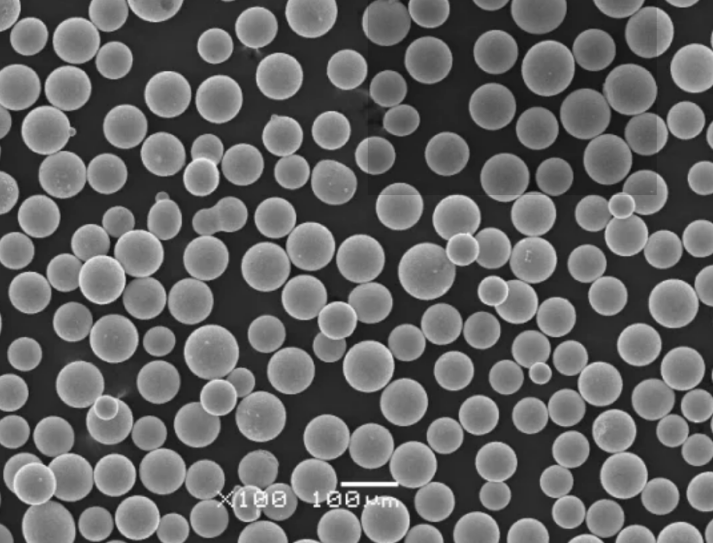

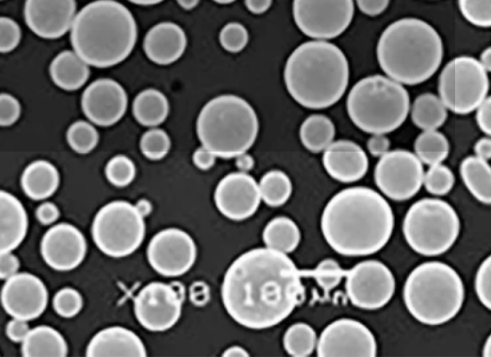

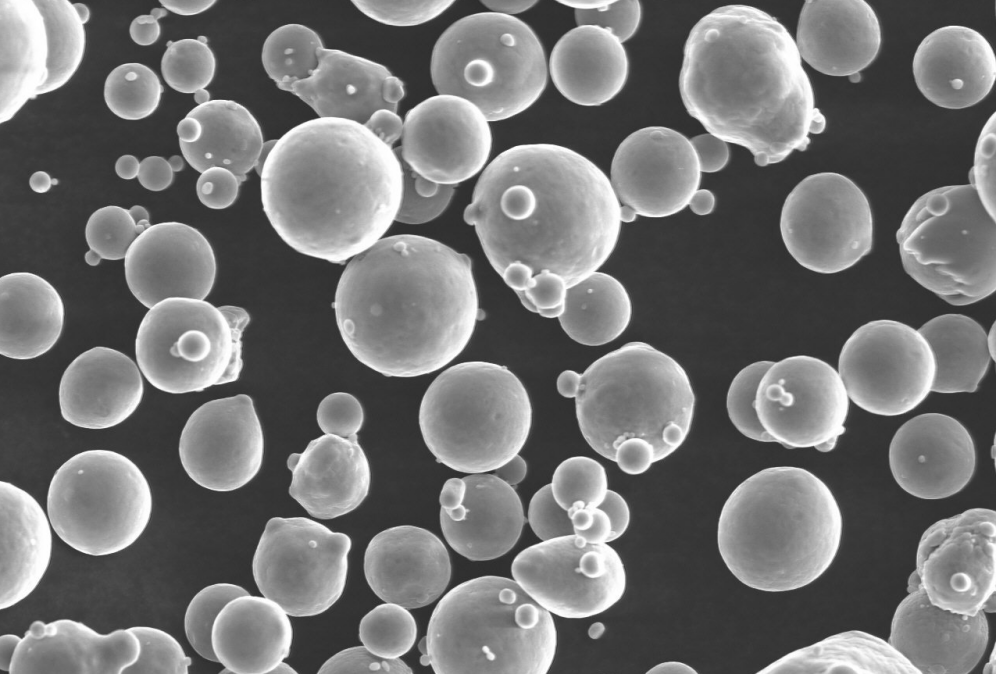

4.1 Feedstock Preparation

In this stage, fine metal powders are mixed with a binder material to form a homogenous feedstock. The metal powder size, binder composition, and mixing parameters are carefully controlled to achieve a consistent feedstock with good flow properties.

4.2 Injection Molding

The feedstock is injected into a mold cavity under high pressure and temperature. The mold is typically made from tool steel and has a cavity that defines the desired shape of the final metal component. The injected feedstock fills the mold cavity, taking its shape and capturing all the intricate details.

4.3 Debinding

After injection molding, the binder material needs to be removed from the molded part. Debinding is typically done through thermal or solvent methods. This process eliminates the majority of the binder, leaving behind a fragile green part.

4.4 Sintering

The debound green part is then sintered in a furnace, where it undergoes a carefully controlled heating and cooling process. Sintering causes the remaining metal particles to bond together, resulting in a fully dense metal component with enhanced mechanical properties.

4.5 Finishing Operations

Once the sintering process is complete, the MiM component may undergo additional finishing operations such as heat treatment, surface treatment, machining, and polishing to achieve the desired surface finish, dimensional accuracy, and functional properties.

5. Applications of MiM Metals

MiM metals find applications in various industries, including:

5.1 Automotive Industry

MiM components are used in automotive applications such as engine parts, transmission components, fuel injection systems, and sensor housings. The ability to produce intricate shapes and achieve high precision makes MiM metals valuable for improving engine efficiency, reducing weight, and enhancing overall performance.

5.2 Medical and Dental Industry

MiM metals are widely used in the medical and dental fields due to their biocompatibility and excellent mechanical properties. They are utilized in the production of surgical instruments, orthopedic implants, dental brackets, and prosthetic components. MiM enables the manufacturing of patient-specific implants with complex geometries for better fit and functionality.

5.3 Electronics Industry

MiM metals are utilized in the electronics industry for manufacturing connectors, sensor housings, and electromagnetic shielding components. Their high electrical conductivity and design flexibility make them ideal for applications where electromagnetic interference (EMI) shielding is crucial.

5.4 Aerospace Industry

MiM components are finding increasing applications in the aerospace sector, where weight reduction, fuel efficiency, and reliability are paramount. MiM metals are used in the production of aircraft engine components, brackets, housings, and structural parts, offering the required strength, corrosion resistance, and design complexity.

6. Comparison with Other Manufacturing Methods

6.1 MiM vs. Conventional Machining

Unlike conventional machining methods, MiM enables the production of complex shapes and fine details without the need for extensive material removal. MiM reduces material waste and improves production efficiency, making it a cost-effective alternative for intricate metal components.

6.2 MiM vs. Investment Casting

MiM offers greater design flexibility and dimensional accuracy compared to investment casting. The injection molding process allows for the creation of intricate features, thin walls, and undercuts that are challenging to achieve through casting. MiM also eliminates the need for expensive tooling and reduces lead times.

6.3 MiM vs. Die Casting

MiM provides higher design complexity and better dimensional accuracy than die casting. Die casting often requires secondary machining operations to achieve the desired part geometry, while MiM can produce complex shapes directly from the mold without additional processing. However, die casting may be more suitable for high-volume production.

7. Limitations of MiM Metals

While MiM metals offer numerous advantages, there are some limitations to consider:

7.1 Material Selection Constraints

Not all materials are suitable for MiM. Some materials may have limited availability in powder form or exhibit challenges during the debinding and sintering processes. Material selection constraints should be considered during the design phase to ensure the compatibility of the chosen material with the MiM process.

7.2 Cost Considerations

MiM can be cost-effective for producing intricate and complex metal components. However, it may not be suitable for high-volume production due to the costs associated with tooling and material selection. Cost analysis should be performed to determine the feasibility of MiM for a specific application.

7.3 Size and Weight Limitations

MiM is most effective for small to medium-sized components due to the limitations of the injection molding process and sintering furnace capacity. Large or heavy parts may be challenging to produce using MiM. Size and weight considerations should be taken into account when determining the feasibility of using MiM for a particular component.

8. Future Trends in MiM Metal Technology

The field of MiM metals continues to evolve, with ongoing research and development focused on enhancing the process and expanding its capabilities. Some future trends in MiM metal technology include:

- Advanced Materials: Researchers are exploring new metal alloys and composite materials that can be processed using MiM, expanding the range of applications and improving material properties.

- Process Optimization: Efforts are being made to optimize the MiM manufacturing process, including feedstock formulation, injection molding parameters, debinding techniques, and sintering conditions. These optimizations aim to improve efficiency, reduce costs, and enhance part quality.

- Scale-Up and High-Volume Production: The industry is working towards scaling up the MiM process to accommodate larger production volumes. This involves advancements in tooling, automation, and process control to meet the demands of industries requiring mass production.

- Integration with Additive Manufacturing: Integration of MiM with additive manufacturing techniques, such as 3D printing, holds promise for creating hybrid components that combine the benefits of both processes. This integration can enable the production of complex parts with tailored material properties.

- Surface Finish and Post-Processing: Researchers are exploring techniques to improve the surface finish of MiM components, reducing the need for extensive post-processing operations. This includes advancements in polishing, coating, and surface treatment methods.

9. Conclusion

MiM metals have revolutionized metal manufacturing by offering exceptional precision, complex geometries, and a wide range of material options. The MiM process, from feedstock preparation to finishing operations, enables the production of intricate metal components for various industries such as automotive, medical, electronics, and aerospace. While MiM has its limitations, ongoing research and development are addressing these challenges and paving the way for future advancements in the field. As technology progresses, MiM is expected to play an increasingly important role in metal component production.

FAQs (Frequently Asked Questions)

- Q: Can MiM metals be used for high-stress applications? A: Yes, MiM metals can exhibit high mechanical strength and are suitable for high-stress applications, such as aerospace and automotive components.

- Q: Are MiM metals cost-effective compared to traditional manufacturing methods? A: MiM can be cost-effective for producing complex and intricate parts, but cost considerations depend on factors such as volume, material selection, and part complexity.

- Q: What are the main advantages of using MiM metals in the medical industry? A: MiM metals offer biocompatibility, high precision, and the ability to produce patient-specific implants with complex geometries, enhancing their suitability for medical applications.

- Q: Can MiM metals be recycled? A: Yes, MiM metals can be recycled by reprocessing the scrap and unused feedstock, reducing material waste and promoting sustainability.

- Q: Are there any size limitations for MiM-produced components? A: MiM is most suitable for small to medium-sized components due to the limitations of the injection molding process and sintering furnace capacity. Larger or heavier parts may pose challenges.