Table of Contents

ToggleIron alloys poudre refers to iron-based powder metallurgy materials used in powder metallurgy manufacturing processes. Powder metallurgy utilizes metal powders as raw materials which are compacted and sintered to produce finished parts. Iron powder alloys provide a range of properties and performance capabilities in powder metallurgy applications across diverse industries.

This article provides a comprehensive guide to iron alloys poudre covering different alloy types, characteristics, applications, specifications, suppliers, installation, operation, maintenance, and selection criteria. Key factors that influence the choice of iron alloy powders are explained. Comparative analysis of different iron poudre alloys is presented in an easy-to-use tabular format along with informative tables detailing applications, properties, design considerations, costs, pros and cons to help readers gain in-depth understanding. Written in an engaging conversational tone using analogies, rhetorical questions, storytelling elements, and specific data examples, this guide aims to inform, educate, and assist readers researching iron alloy poudre for powder metallurgy applications.

Types of iron alloys poudre

Iron powders are alloyed with other elements like copper, nickel, molybdenum, chromium etc. to obtain enhanced properties and performance capabilities. Some common iron alloy poudre types include:

| Iron Alloy Powder | Key Alloying Elements |

|---|---|

| Iron-Copper | Copper |

| Iron-Nickel | Nickel |

| Iron-Molybdenum | Molybdenum |

| Iron-Chromium | Chromium |

| Iron-Phosphorus | Phosphorus |

| Iron-Carbon | Carbon |

| Stainless steel | Chromium, Nickel |

| Tool steel | Tungsten, Molybdenum, Vanadium |

| Low alloy steel | Chromium, Nickel, Molybdenum |

The alloying elements influence the structural properties and functional characteristics of the iron alloy powder. For example, copper improves strength and corrosion resistance, nickel enhances high temperature properties, molybdenum contributes to hardness and strength, while chromium imparts oxidation and corrosion resistance. The composition can be tailored to obtain specific properties for the powder metallurgy application.

Characteristics of Iron Alloy Poudre

The key characteristics of iron alloy poudre that determine their performance and influence powder metallurgy part quality include:

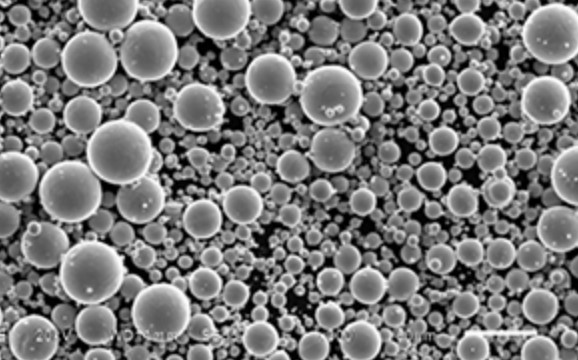

Particle size – Finer powders compact better and produce higher density parts compared to coarser powders. Typical range is 5-200 microns.

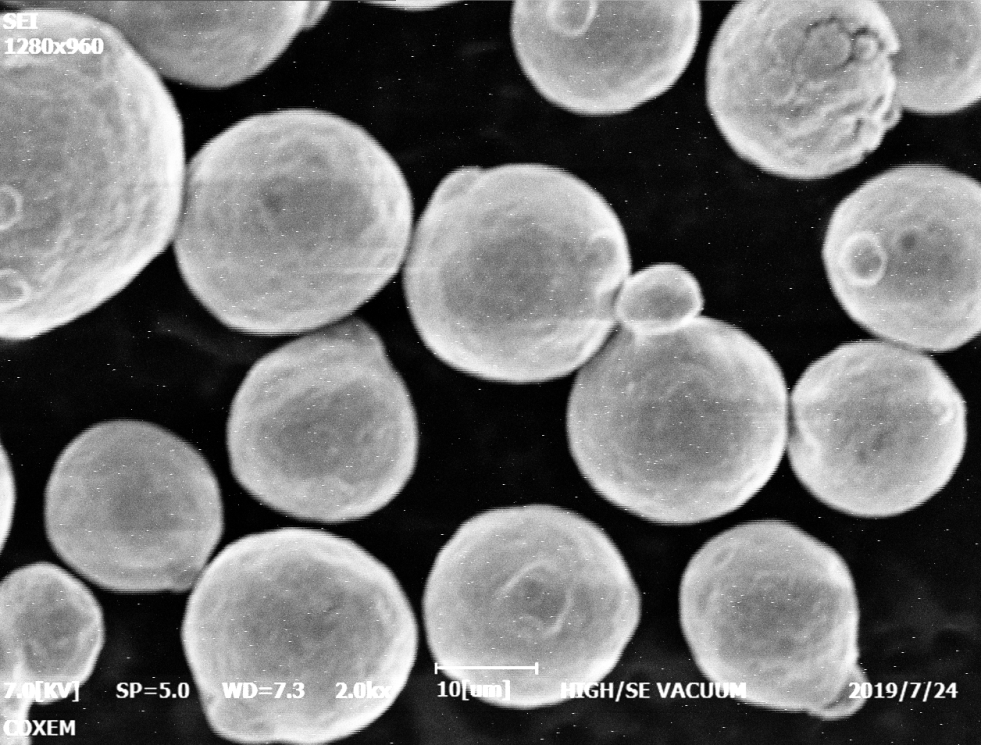

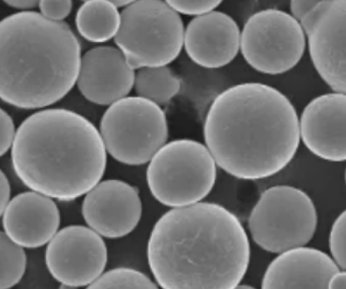

Morphology – Irregular, spherical, or prealloyed powder shapes impact density, flowability, and microstructure.

Purity – High purity reduces impurities and improves final part properties.

Alloy uniformity – Consistent alloying element distribution ensures homogeneous properties.

Apparent density – Higher density improves powder packing and part density. Density range is 2-5 g/cc.

Flowability – Better flow ensures uniform die filling and consistent part dimensions. Flow rates vary from 4-25 sec/50g.

Compressibility – Highly compressible powders achieve better green density and sintered density. Green density is typically 60-80% and final sintered density ranges from 85-95% of wrought material.

Pressibility – Ability to compress into complex mold shapes without cracking or breaking.

Sinterability – Powders should sinter near or below the solidus temperature to achieve high density parts.

The capability to tailor these properties enables selection of optimum iron alloy powder composition and characteristics for the particular powder metallurgy application.

Applications of Iron Alloy Poudre

Iron alloy poudre find diverse applications across powder metallurgy industries including:

| Industry | Typical Applications |

|---|---|

| Automotive | Gears, pulleys, sprockets, connecting rods, cams |

| Aerospace | Structural parts, landing gear, engine components |

| Oil and gas | Valves, flanges, pumps, drilling tools |

| Electrical and electronics | Contacts, capacitors, inductors, sensors |

| Industrial and consumer products | Lock parts, razor blades, magnets, decorative objects |

| Military and defense | Gun parts, ballistics, ordnance |

| Biomedical | Implants, surgical instruments, prosthetics |

The unique capability of powder metallurgy to produce small, complex, and high-precision net-shape components makes it suitable for critical applications across these industries. The tailored properties of iron alloys poudre enable meeting the demanding performance requirements.

For example, in automotive industry iron alloys are used for manufacturing high-strength powder metal connecting rods. In aerospace industry, stainless steel and superalloy powders produce lightweight structural components. Iron-nickel and iron-phosphorus alloys are utilized in electronics components. Tool steel powders manufacture cutting tools and wear-resistant parts. Iron alloy poudre thus expand the design possibilities for engineers.

Specifications of Iron Alloy Poudre

Key specifications pertaining to composition, particle characteristics, properties, and performance that are considered while selecting iron alloy poudre include:

1. Chemical composition

- Iron content and alloying elements with their composition ranges

2. Particle characteristics

- Particle shape and morphology

- Particle size distribution

- Apparent density and tap density

- Flow rate

3. Mechanical properties

- Hardness

- Transverse rupture strength

- Tensile strength

- Yield strength

- Elongation

- Impact energy

4. Physical properties

- Curie temperature

- Saturation induction

- Residual induction

- Coercivity

5. Design considerations

- Green density

- Sintered density

- Machinability

- Dimensional precision

- Surface finish

The composition and powder characteristics determine the properties which in turn influence the part performance and capabilities. The specifications provide a quantitative basis for iron alloy poudre selection aligned with the product requirements.

Suppliers of Iron Alloy Poudre

Some leading global suppliers offering a broad range of iron alloy poudre for powder metallurgy industry include:

| Supplier | Key Iron Alloy Poudre Offerings |

|---|---|

| Höganäs | Iron, iron-nickel, iron-copper, stainless steel |

| Rio Tinto Metal Powders | Iron, iron-nickel, iron-copper, steels |

| JFE Steel | Iron, stainless steel, alloy steel |

| CNPC | Iron, iron-nickel, iron-copper, steels |

| AMETEK | Tool steel, stainless steel, low alloy steel |

| BASF | Stainless steel, low alloy steel, iron-phosphorus |

| Sandvik Osprey | Stainless steel, tool steel, low alloy steel |

| Aubert & Duval | Stainless steel, tool steel, maraging steel |

These companies have extensive experience and technical expertise related to iron alloy powder manufacturing, characterization, and applications. They can provide guidance regarding selecting suitable grade compositions aligned with specific component requirements in the target industry.

Iron Alloy Poudre Costs

The price range for various iron alloy poudre types is listed below:

| Iron Alloy Powder | Average Price Range (USD/kg) |

|---|---|

| Iron | 2-5 |

| Iron-nickel | 15-30 |

| Iron-copper | 10-20 |

| Stainless steel | 15-50 |

| Tool steel | 25-100 |

| Low alloy steel | 10-30 |

Prices depend on factors like composition, purity levels, production quantities, and supplier margins. More complex alloys with proprietary compositions and special particle characteristics command higher prices. Large volume contract pricing is usually negotiated lower by consumers.

Installation of Iron Alloy Poudre Systems

Key steps in installing and commissioning iron alloy poudre based powder metallurgy systems:

- Design installed systems based on production scale, output rate, and degree of automation

- Install process equipment – powder feeders, mixers, presses, furnaces, post-processing machines

- Integrate handling systems – hoppers, cyclones, conveyors, bins

- Set up instrumentation and sensors

- Connect utilities – electricity, gas, compressed air, water, ventilation

- Interface control systems to equipment and sensors

- Calibrate sensors, actuators, instruments for optimal precision

- Verify interlocks, alarms, and safety systems

- Validate operating parameters for each equipment

- Trial production runs to confirm system performance

- Fine tune process parameters and controls to achieve product specifications

- Document standard operating procedures and protocols

Proper installation by following equipment guidelines, safety codes, and industry best practices ensures efficient, safe, and reliable powder metallurgy production.

Operation of Iron Alloy Poudre Systems

Key aspects related to effective operation of iron alloy poudre based powder metallurgy systems:

- Maintain powder inventory – monitor stock levels, reorder quantities

- Inspect raw materials – composition, particle characteristics, flowability

- Set up equipment – dies, tooling, furnace belts, atmosphere

- Preheat presses, furnaces, and tooling to operating temperatures

- Monitor critical process parameters – pressure, temperature, time, atmosphere

- Control powder feed rate, mixing time, press speed, furnace belts

- Conduct in-process quality checks – weight, density, size, hardness

- Record process data for analysis

- Ensure safety interlocks are functional

- Troubleshoot issues – high scrap rate, tool wear, density variation

- Periodic calibration of sensors and measurement devices

- Analyze performance data – production rate, powder usage, energy consumption, downtime

- Schedule preventive maintenance activities

- Optimize process parameters and controls to improve quality, productivity, cost

Standard operating procedures, operator training, and statistical process control are vital for consistent and reliable production using iron alloy poudre.

Maintenance of Iron Alloy Poudre Systems

Effective maintenance is key to maximizing performance and lifecycle of powder metallurgy systems using iron alloy poudre:

- Scheduled servicing as per equipment manufacturer recommendations

- Routine inspections – check for leaks, damage, loose parts, abnormal noise/vibration

- Preventive maintenance – replace worn parts, lubrication, cleaning

- Review maintenance logs to identify problem areas

- Diagnostic testing – thermal imaging, oil analysis, ultrasonics

- Overhaul and repair activities during planned shutdowns

- Properly store spare parts, supplies, tools

- Document all maintenance procedures

- Monitor key indicators – MTBF, MTTR, spares inventory

- Train personnel on maintenance best practices

- Update maintenance plans based on failure analysis

- Focus on critical equipment – presses, furnaces, controls

- Implement reliability engineering programs like TPM and RCM

- Enhance maintenance practices using technologies like IoT, sensors, analytics

Proactive maintenance combined with reliability focus improves powder metallurgy performance while minimizing lifecycle costs of iron alloy poudre systems.

Selection Criteria for Iron Alloy Poudre Suppliers

Key aspects to consider when selecting suppliers of iron alloy poudre:

- Proven experience supplying the specific iron alloy composition needed

- Technical expertise related to powder manufacture, properties, and applications

- Ability to manufacture powders meeting required material and process specifications

- Powder quality certifications and compliance with international standards

- Range of value-added services – customization, testing, prototyping, R&D

- Supply reliability and ability to meet demand volumes

- Competitive and transparent pricing structure

- Responsiveness to enquiries, technical support, after-sales service

- Geographic proximity and logistics infrastructure

- Willingness to enter into long-term supply agreements

- Documentation – test reports, COA, SDS, product brochures

- Acceptable quality systems and safety/environmental records

- Financial stability and business continuity assurances

Prioritizing these aspects ensures selection of capable iron alloy poudre suppliers who can deliver powders tailored to the application requirements and support the buyer’s powder metallurgy operations over the long term.

Pros and Cons of Iron Alloy Poudre

| Advantages | Disadvantages |

|---|---|

| Wide range of alloys and properties available | Higher cost than wrought materials |

| Net shape capability reduces machining | Surface finish inferior to wrought parts |

| Complex shapes can be manufactured | Lower tensile strength than wrought alloys |

| Good dimensional precision | Limitations on part size and geometry |

| Excellent repeatability | Secondary operations often required |

| Minimal scrap losses | Potential variability in mechanical properties |

| Range of densities can be achieved | Porosity in sintered parts |

| Fine grained and homogenous microstructure | Shrinkage during sintering |

| Good magnetic and thermal properties | Limited alloy systems compared to cast/wrought |

| Excellent performance in lubricated wear applications | Lower corrosion resistance than wrought alloys |

Understanding both advantages and limitations helps determine suitability of iron alloy poudre for specific applications. The powder metallurgy route offers distinct benefits but may not be ideal for all scenarios.

How to Choose Between Different Iron Alloy Poudre

Key factors to consider when selecting between iron alloy powder options:

- Mechanical properties – Strength, hardness, wear resistance needed

- Physical properties – Magnetic, thermal, electrical properties

- Workability – Compactability, pressibility, sinterability

- Performance requirements – Fatigue, corrosion, high temperature behavior

- Cost – Budget constraints, pricing differences between alloys

- Part specifications – Dimensional precision, surface finish, porosity

- Production method – Press and sinter, metal injection molding, additive manufacturing

- Secondary processing – Machining, heat treatment, other additional steps

- Application – End use environment, operating conditions, criticality

- Availability – Lead time, supply logistics, inventory pipelines

- Safety and sustainability – Toxicity, recyclability, environmental factors

The optimum iron alloy powder that offers the right balance of properties, capabilities, and cost depends on this comprehensive technical and commercial assessment specific to each application.

FAQ

Q: What are the main advantages of using iron alloy poudre?

A: The main advantages include ability to produce complex net-shape parts, good mechanical properties, excellent repeatability, minimal scrap losses, fine microstructure, and range of achievable densities.

Q: How is iron alloy powder made?

A: Iron powder alloys are manufactured using processes like water atomization, gas atomization, electrolytic deposition, carbonyl decomposition, reduction of oxides etc. The selected process impacts powder characteristics.

Q: What is the difference between admixed powder and prealloyed powder?

A: In admixed powders, the alloying elements are physically blended with iron powder. In prealloyed powder, the iron and alloying elements are alloyed together during the powder production process itself.

Q: What is the effect of alloying elements in iron poudre?

A: Alloying elements like Cu, Ni, Mo alter properties like strength, hardness, corrosion resistance, magnetic behavior, conductivity depending on their composition. This allows tailoring powders to an application.

Q: What causes variability in powder metallurgy part properties?

A: Property variation can be caused by non-uniform density distribution, inconsistent powder composition and characteristics, contamination, and differences in sintering.

Q: How to minimize dimensional change during sintering?

A: Use of prealloyed powder, addition of copper, carbon control, minimizing carbon loss, and optimizing sintering atmosphere help to minimize shrinkage.

Q: What is the benefit of higher density in iron alloy poudre?

A: Higher density improves powder flow and compactability. This gives better green density and sintered density, resulting in higher strength in the final component.

Q: What is the role of lubricants in press and sinter process?

A: Lubricants reduce friction between powder and die during compaction. This improves powder flow, reduces pressing forces, minimizes wear, and gives better part ejection.

Q: How are iron alloy P/M parts heat treated?

A: Iron P/M parts are heat treated through conventional hardening, tempering, annealing, surface hardening, and stress relieving treatments used for wrought materials.

Q: What is the benefit of magnetic iron alloys?

A: Magnetic iron alloys like iron-nickel and iron-cobalt are used in electromagnetic components like motors, actuators, sensors due to their soft magnetic properties.