Table of Contents

ToggleIron powder is a versatile ferrous material with diverse industrial and commercial applications owing to its magnetic properties, high strength, ductility and range of available powder sizes. This guide details different types, specifications, manufacturing methods, applications, pricing, comparisons and frequently asked questions about iron powder.

Overview of Iron Powder

Iron powder refers to fine granules of iron metal, usually below 500 microns in size. It exhibits high permeability and often contains small amounts of alloying elements like silicon, nickel, molybdenum or copper to modify magnetic or structural properties.

Key attributes making iron powders useful across industries:

- High purity iron content (>98%)

- Controlled powder morphology and grain size

- Range of electrical resistivity values

- Adjustable magnetic properties

- Good machinability and compressibility

- Capability to tailor mechanical strength

- Availability in large commercial quantities

- Lower fabrication costs than solid iron

- Recyclability of scrap/waste powder

With global demand projected to reach 800 kilo tons annually, iron powder production and variety continues rising driven by automotive, electrical and brazing industry applications.

Types of Iron Powder Compositions

Iron powder is commonly categorized by composition, manufacturing process, particle shape, powder size and powder density:

Table 1: Main types of iron powder compositions

| Type | Description |

|---|---|

| Carbonyl iron | Ultrafine high purity powder produced via iron pentacarbonyl decomposition |

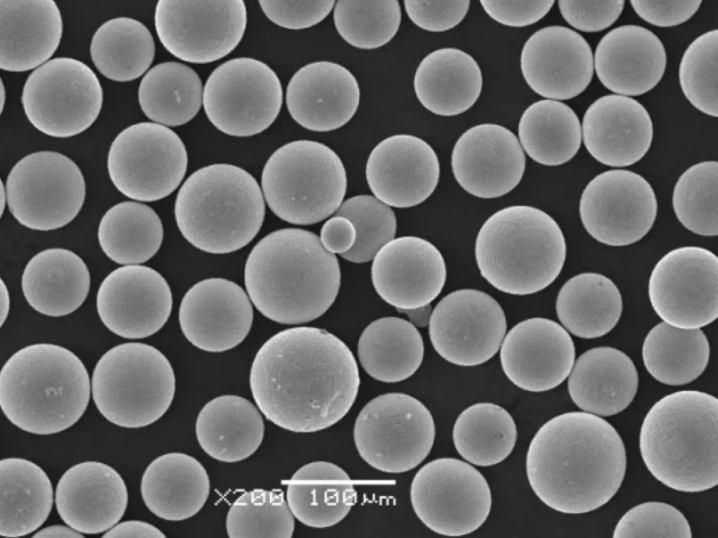

| Water atomized | Made by atomization of molten iron pumped through nozzle; irregular shapes |

| Electrolytic | Deposited from aqueous iron salt solutions onto cathodes |

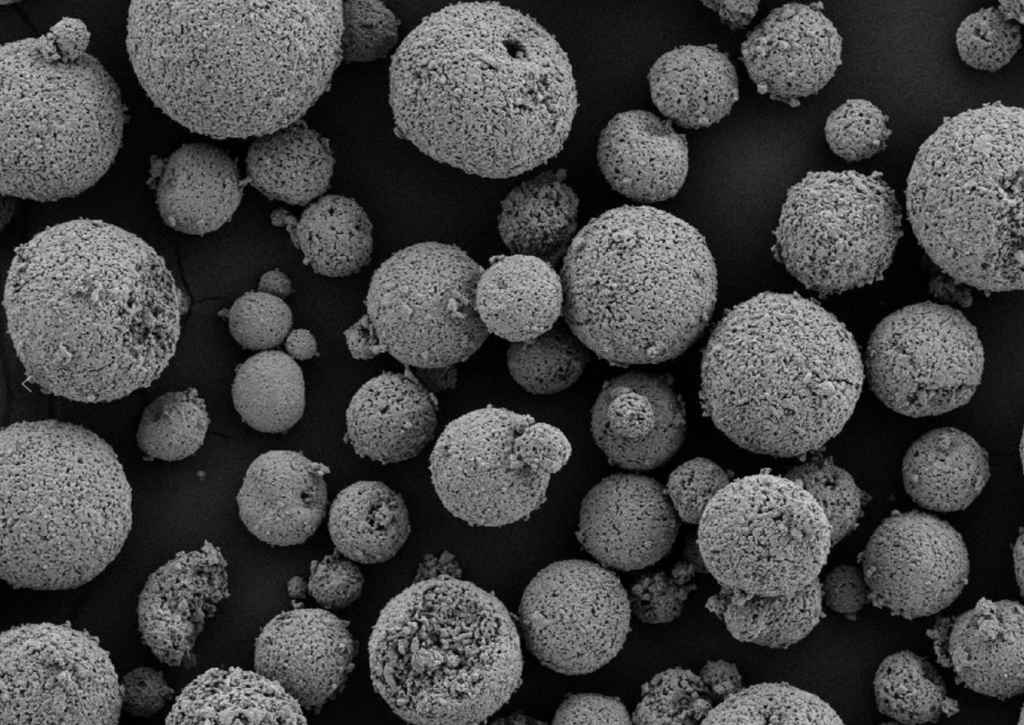

| Reduced iron | Produced from mill scale via H2/CO reduction at 400-700°C |

| Annealed | Soft powder generated by annealing electrolytic/water atomized powder |

| Alloyed | Small additions of Si, Al, Cu, Mo to modify powder properties |

| Insulated iron | Each particle coated with inorganic insulating layer |

| Sand iron | Irregular chunks made via crushing/milling cast iron |

Shape: Predominantly spherical, dendritic, granular and irregular chunky particles seen.

Size: Between 10 microns to 1 millimeter; smaller is costlier.

Apparent density: 2 gr/cc lightly packed, up to 4 gr/cc for press-compacted powder.

Besides composition, properties are determined by powder production methods and post-processing like annealing, coatings or lubricant addition.

Key Characteristics and Properties of Iron Powder

Commercially available iron powder exhibits a wide spectrum of physical, chemical, electrical and magnetic characteristics:

Table 2: Iron powder properties and test measurement methods

| Property | Typical Values | Test Methods |

|---|---|---|

| Chemical composition | >98% Fe, <0.8% O2, <0.1% N2, <0.1% C | Combustion analysis, XRF |

| Apparent density | 2-4 gr/cc | Hall flowmeter |

| Tap density | Up to 6.5 gr/cc | binding fraction |

| Flow rates | Cohesion affects powder flow under gravity | Hall flowmeter |

| Compressibility | Green compression of 35-65% typical | Press tool tests |

| Hydrogen loss | Below 150 ppm from annealing | Inert gas fusion method |

| Permeability | 70-150 for annealed iron | Hysteresisgraph testing |

| Resistivity | 10-18 μOhm-cm; alloying reduces | Four probe method |

| Loss factor | Below 15 kW/m3 at 10 kHz | Hysteresisgraph |

| Hardness | Up to 90 HRB post sintering | Rockwell hardness |

Key factors that determine suitability for industrial usage:

- Flow characteristics

- Density consistency

- Magnetic potential

- Fabrication amenability

- Purity level

- Particle size distribution

Production Processes for Iron Powder

The principal manufacturing routes for generating different grades of iron powder are:

Table 3: Overview of key iron powder production processes

| Method | Description | Typical Output |

|---|---|---|

| Gas atomization | Molten iron stream disintegrated by nitrogen/argon jets | Fine spherical powder |

| Water atomization | High pressure water breaks up iron melt into granules | Irregular dendritic powder |

| Electrolysis | Iron ions from aqueous solution plated onto cathode | Light spongy deposits |

| Carbonyl decomposition | Thermal cracking of iron pentacarbonyl | Ultrafine high purity powder |

| Mechanical comminution | Cast/pig iron crushing and grinding | Large grain sized powder |

| Hydrogen reduction | Iron oxide powder reduced in hydrogen atmospheres | Porous less dense powder |

| Electro-deposition | Electroplating iron onto cathodes from soluble anodes | Dense adherent powder |

Post-production secondary processes like annealing, crushing, classifying, coating and lubrication can further modify powder properties like grain size, shape, density and flow characteristics.

Table 4: Industry providers of iron powder manufacturing equipment and systems

| Company | Offerings |

|---|---|

| BASF | Gas atomization equipment |

| Sandvik Osprey | Water atomization turnkey systems |

| Italprocess | Hydrogen reduction units |

| ECKA Granules | Annealing, crushing, classifying |

| Höganäs | Complete powder production solutions |

| Kastwel | Powder processing equipment |

200-2000 kg/hour production capacities are typical for gas, water and hydrogen based reduction plants.

Applications and Uses of Iron Powder

The major industrial applications and commercial uses of iron powder include:

Table 5: Major application areas for iron powder

| Industry | Applications |

|---|---|

| Automotive | Powder metal gears, engine bearings, oil pump components, brake pads, friction parts |

| Electrical | Ferrites, inductors, electromagnetic shielding, contacts |

| Construction | Powder coating feedstock for finishes over metal substrates |

| Manufacturing | Powder injection molding of complex net shape parts |

| Filtration | Water treatment using iron media for removal of arsenic, chromium contaminants |

| Printing | Toner powders for photocopiers, laser printers |

| Welding | Binder in exothermic welding flux mixtures generating heat |

| Metallurgy | Iron powder additions enhance mechanical properties of sintered steels |

| Chemical | Used as catalyst and pigment source |

| Lubricants | Friction control additive to brake fluids, transmission oils |

| Microwave | Iron lossy material for electromagnetic wave absorption |

Of these, powder metallurgy and friction component fabrication account for over 50% of iron powder consumption presently.

Iron Powder Specifications

Iron powder is commercially marketed in various standard grades defined by particle size, shape, density and composition:

Table 6: Typical specifications of iron powder grades available

| Attribute | Range |

|---|---|

| Size range (microns) | 10 to 500 |

| Shape | Spherical, granular, dendritic |

| Alloying elements | Cu: 1-4%, Mo: 0.2-5%, Si: 0.1-6% |

| Apparent density (g/cc) | 2-4.5 |

| Tap density (g/cc) | up to 6.5 |

| Minimum iron assay | 98% |

| Maximum oxygen | 0.8% |

| Maximum nitrogen | 0.1% |

| Moisture content | <0.1 wt % |

| Flow rates | Cohesion affects powder flow under gravity |

Besides these, carburization and insulated iron powder have special subsets of grade specifications tailored to unique applications.

International Standards for Iron Powder

Globally traded iron powder conforms to established quality parameters as per industrial standards:

Table 7: Major international iron powder grade standards

| Standard | Key Aspects Defined |

|---|---|

| ISO 4491 | Method to empirically determine powder flow rates using Hall flowmeter |

| ISO 4490 | Bulk density and tap density measurement procedures |

| ISO 4497 | Sieving techniques to determine particle size distribution |

| ASTM B831M | Standard test methods for particle size distribution of metal powders via sieving |

| JIS Z 2508 | Japanese standard specifying methods for determining compression and green density characteristics |

| DIN 51733 | German standard test procedures for assessing powder flow properties |

Reputable manufacturers have quality certifications like ISO 9001 along with fully equipped laboratories to validate chemical, functional and physical properties during production and for user acceptance.

Suppliers and Pricing

As a mass commodity product produced by major metal powder manufacturers, current pricing for iron powder varies from $1.5 to $5 per kilogram based on:

Table 8: Key determinants of iron powder pricing

| Parameter | Impact on Price |

|---|---|

| Production process | Electrolytic and carbonyl most expensive |

| Purity level | Higher purity commands premium |

| Powder density | Increase with more compressibility |

| Particle size | Finer powder costs more |

| Purchase quantity | Bulk ordering gives discounts |

| Product consistency | Tight distribution tolerances add cost |

| Alloying elements | Most alloy grades cost extra |

| Location | Regional freight and duties affect |

Table 9: Major global suppliers and typical price ranges for their iron powders

| Company | Product Forms | Price Range |

|---|---|---|

| Höganäs | Water atomized, prealloyed | $1.8–$3.5/kg |

| BASF | Carbonyl, electrolytic, water atomized | $2–$4.8/kg |

| Rio Tinto | Water atomized, annealed, hydrogen reduced | $1.7–$3/kg |

| CNPC | Electrolytic, alloyed grades | $1.5–$2.5/kg |

| JFE Steel | Carbonyl, alloyed atomized | $2–$5/kg |

| Sandvik Osprey | Gas atomized | $3.5–$5/kg |

| AMETEK | Fine stainless steel clad | $5–$7/kg |

Prices depend on annual contracted volumes and width of specification guaranteed. Make quality consistency and certification a priority over merely chasing lowest quoted pricing levels while sourcing iron powder.

Pros and Cons of Iron Powder

Table 10: Comparison between advantages and limitations of iron powders

| Advantages | Disadvantages |

|---|---|

| Economical material and processing | May not match cast/wrought properties |

| Easily molded into net shapes | Lower strength than steel alloys |

| Range of magnetic permeabilities | Prone to rusting without protective finishes |

| Higher ductility than most ferrites | Limited formability for sheet metal fabrications |

| Process scrap recyclable | Powder handling precautions needed |

| Uniformity tailorable via processing | Property variability between batches possible |

For small complex parts like sprockets and gears, powder metallurgy route offerssignificant cost benefits even accounting for lower mechanical strength. But for large structural fabrications, traditional casting or deformation processing of steel is better.

FAQ

Q. How is iron powder classified based on particle sizes?

Iron powder is commercially classified by mesh sizes into:

- Coarse grades – below 100 mesh size (149 microns)

- Fine grade – 100 to 400 mesh (37 to 149 microns)

- Ultra fine grade – over 400 mesh, Below 37 microns

Q. Which grades provide the highest purity iron powder?

Purity levels over 99.5% is possible with carbonyl and electrolytic iron powder. Atomization methods generate >98% purity.

Q. What is the difference between apparent density and tap density?

Apparent density refers to loose packing measured after gentle agitation while tap density is the increased compaction achieved after mechanically tapping loaded measurement cylinder.

Q. Why is flow rate an important iron powder parameter?

Good powder flow ensures ease, consistency and automation suitability for part molding and metallurgy processes like metal injection molding where the material has to flow freely under gravity into dies.