Table of Contents

Togglemim metal powder is a manufacturing process where a metal powder feedstock is injected into a mold to produce complex, high-density metal parts. The MIM process combines the design flexibility of plastic injection molding with the strength and integrity of machined metal parts.

MIM powder refers to the metal powders used as the raw material in the MIM process. The composition and characteristics of the MIM powder have a significant influence on the properties, quality, and cost-effectiveness of MIM parts.

MIM Powder Types and Composition

MIM powders are available in a wide range of alloys, including stainless steel, tool steel, magnetic alloys, copper alloys, super alloys, and titanium alloys. Iron, nickel, and cobalt constitute the base of most MIM powders.

The most common categories of MIM metal powders include:

| MIM Powder Type | Composition |

|---|---|

| Stainless steel | Fe-Cr-Ni + trace elements like Mo, Ti, Nb |

| Tool steel | Fe-Cr-Mo-V + carbide formers like W, Cr |

| Soft magnetic alloys | Fe-Si, Fe-Ni, Fe-Co + Cu, Nb etc |

| Copper alloys | Cu-Zn, Cu-Al, Cu-Sn etc. |

| Super alloys | Ni/Co-Cr + Al, Ti, Nb, Ta, W etc. |

| Titanium alloys | Ti-Al-V, Ti-Mn, Ti-Mo etc. |

The exact composition can be varied to obtain specific properties required by the application. Trace elements are carefully controlled.

The composition and alloy chemistry determine the performance, processability, and price of the MIM powder.

MIM Powder Properties and Characteristics

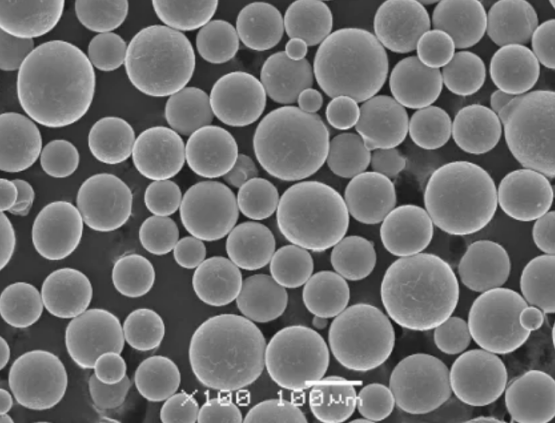

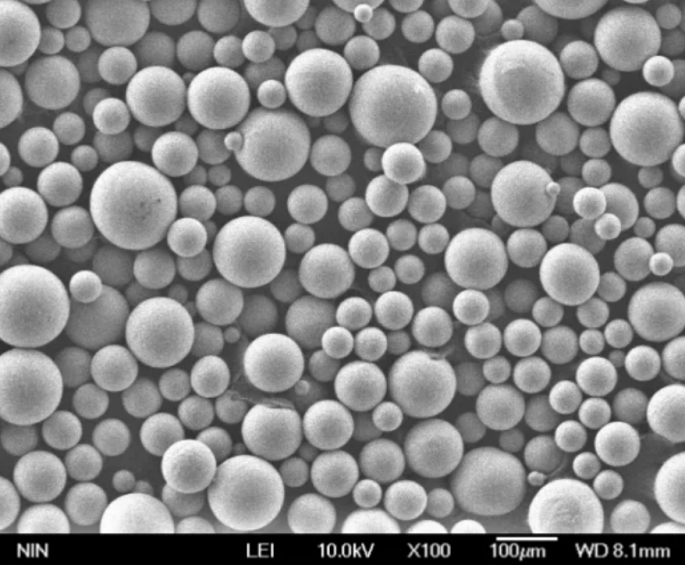

In addition to composition, MIM powders have certain physical and chemical properties that make them suitable for the MIM process:

Table 1: Key properties and characteristics of MIM powders

| Property | Desired Values | Significance |

|---|---|---|

| Particle size | 10-20 μm | Affects powder flow and packing density |

| Morphology | Spherical, satellite-free | Determines powder flowability |

| Oxygen content | <0.5% | Impacts debinding and sintering |

| Apparent density | >80% of true density | Influences final part density |

| Tap density | >90% of true density | Determines mixing and flow behavior |

| Hausner ratio | <1.25 | Indicates powder flowability |

| Pycnometric density | As per alloy | Sets upper limit of final part density |

| Flow rate | >28 s/50 g | Ensure smooth injection molding |

Precise control over powder characteristics like particle size, shape, density, and flow is needed to produce high quality MIM parts.

Applications and Uses of MIM Powder

MIM is used to manufacture small, complex parts with excellent mechanical properties across industries like:

Table 2: Major applications of MIM powders

| Industry | Typical Applications | Alloy Grades Used |

|---|---|---|

| Aerospace | Turbine blades, impellers | Nickel superalloys, titanium alloys |

| Automotive | Gears, connecting rods | Stainless steels, tool steels |

| Consumer | Watch bodies, orthodontic brackets | Stainless steels, titanium alloys |

| Electronics | Sensors, connector pins | Magnetic alloys, copper alloys |

| Medical | Scalpel blades, forceps | Stainless steels, tool steels |

| Firearms | Triggers, hammers, slides | Stainless steels, tool steels |

MIM allows consolidation of multiple parts into one complex component. The flexibility of MIM powders enables their use across diverse, high-value industries.

MIM Powder Specifications and Standards

MIM powders are available in various standard and custom grades tailored to industry/application needs:

Table 3: MIM powder specifications, sizes, standards

| Standard | Grades | Particle Size | Chemistry |

|---|---|---|---|

| ASTM F2885 | Common grades like SS316L, SS17-4PH, SS410, Inconel 718 | 16-20 μm | Defined as per alloy type |

| ISO 22068 | Equivalent grades | Similar to ASTM | Similar to ASTM |

| Epma/MIMA GUIDES | Custom grades possible | 10-22 μm typical | Customer specified |

Most MIM powder manufacturers offer standard as well as custom grades aligned to industry requirements.

Special grades are possible for more demanding applications in aerospace, medical etc.

MIM Powder Suppliers and Pricing

The following major global suppliers provide high-quality MIM powders:

Table 4: Major MIM powder suppliers and indicative pricing

| Supplier | Grades Offered | Prices |

|---|---|---|

| Sandvik Osprey | Extensive grade portfolio | $$$ |

| Hoganas | Leading grades | $$ |

| AMES Group | Tailored grades | $-$$ |

| BASF | High purity grades | $$$ |

| Kymera International | Wide range | $-$$ |

Prices range from $20/kg for common stainless steel grades to $200/kg for exotic superalloys, depending on order volumes and exact composition.

MIM powders require stringent quality control and significant processing, reflected in premium pricing of finished grades.

Pros and Cons of MIM Powder

Table 5: Advantages and limitations of MIM powders

| Advantages | Limitations |

|---|---|

| Complex, net shape parts | Higher part cost vs other processes |

| Excellent mechanical properties | Limited size range |

| Wide material flexibility | Restricted geometries |

| Proven across industries | Requires high expertise |

The MIM process enables high-performing metal parts unachievable by other techniques, provided design guidelines are followed.

MIM powder has expanded MIM application scope despite its associated higher part cost.

FAQ on MIM Metal Powder

Q: What is the typical MIM powder composition?

A: Most MIM powders are iron, nickel, or cobalt-based alloys with 15-30% chromium, up to 20% molybdenum, trace additions of titanium, niobium etc. Powder composition is matched to application requirements.

Q: What powder characteristics are most critical for MIM feedstock?

A: Particle size, morphology, apparent density, flow rate and oxygen content have the largest influence on MIM feedstock behavior and sintered part properties. These powder attributes need tight control.

Q: Does the MIM process allow precious metal use?

A: Yes, precious metals like gold alloys, sterling silver can be readily MIM’ed for jewelry and high-value applications, owing to 100% material utilization of MIM.

Q: What standards guide MIM powder specifications?

A: Key standards include ASTM F2885, ISO 22068 and industry body guides from Epma, MIMA, which list common grades and test procedures. Custom grades are also possible.

Q: How is MIM powder pricing determined?

A: MIM pricing depends strongly on composition, production volume, quality level and processing method. In general, cost escalates for highly clean, spherical, customized powders.

Conclusion

MIM continues to displace conventional manufacturing routes across diverse industries, enabled by the specialized MIM powders tailored to each application. Through stringent quality control and alloy innovation, MIM powder suppliers like Sandvik Osprey and BASF ensure optimal feedstock performance and sintered part quality batch after batch, facilitating wider adoption of metal injection molding.