Table of Contents

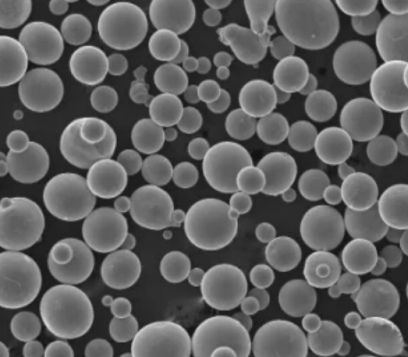

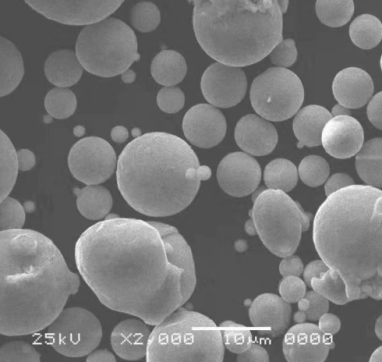

ToggleGas atomization is an industrial process used to produce fine metal powders with precise particle sizes and distributions. It involves melting metal and disintegrating the melt stream into fine droplets using high-velocity gas jets. The droplets rapidly solidify into powder particles in ideal spherical morphologies.

Overview of Gas Atomization Process

What is Gas Atomization?

Gas atomization is a materials processing technique in which a pressurized gas jet is used to break up a molten metal stream into fine droplets. As the droplets travel through the atomization chamber they solidify rapidly into spherical powder particles with a controlled size distribution.

How Does Gas Atomization Work?

The key steps in gas atomization are:

- Metal charge is melted in a crucible or induction furnace to temperatures above liquidus

- The liquid metal stream flows through a tundish into a pour tube

- High velocity inert gas jets impinge on the metal stream, disintegrating it into droplets

- Droplets fall through a cooling column, solidifying into powder particles

- Powder is collected at the bottom of the chamber

What Are The Advantages of Gas Atomization?

Compared to other atomization methods, key benefits are:

- Generates highly spherical powders ideal for additive manufacturing

- Achieves smaller powder sizes and narrower distributions

- Environmentally cleaner and more energy efficient

- Better control over powder characteristics

- Adaptable to reactive alloys and high temperature metals

What Materials Can Be Gas Atomized?

A wide range of alloys can be gas atomized, including:

- Titanium alloys

- Nickel superalloys

- Cobalt superalloys

- Tool steels

- Stainless steels

- Copper alloys

- Aluminum alloys

- Magnesium alloys

- Refractory metals

Nearly any metal with suitable melting characteristics can be gas atomized into powder.

How Does The Gas Atomization Process Work?

Gas Atomization System Components

A gas atomization system contains the following main components:

- Melting Unit – Typically an inductively heated crucible or furnace to melt the metal charge

- Tundish – An intermediate pouring vessel that feeds the liquid metal into the pouring tube

- Pour Tube – A specially designed tube for smooth laminar flow of the metal stream

- Gas Jets – High speed nozzles which atomize the melt into fine droplets

- Drop Tube/Cooling Column – Chamber where droplets solidify into powder

- Powder Collection System – Cyclones and filters to collect the atomized powder

- Exhaust System – To safely remove used atomization gases

How The Atomization Process Works Step-By-Step

- Metal charge is inductively melted above liquidus temperature in crucible

- Molten metal flows from crucible into a tundish vessel

- Tundish controls and stabilizes flow into an enclosed pour tube

- Pressurized inert gas is forced through jets at sonic velocity

- Gas jets impinge on the liquid stream, shearing it into droplets

- Droplets fall through the cooling column, rapidly solidifying into powders

- Powder particles are separated from gases using cyclones and filters

- High velocity gas exhausts through dampers to depressurize safely

So in summary, a controlled molten metal stream meets high speed gas jets which disintegrate it into uniformly sized droplets that solidify into spherical powder particles.

Gas Atomization vs Other Atomization Methods

How Does Gas Atomization Differ From Water Atomization?

- Gas atomization uses gas jets rather than water to break up the melt

- Achieves smaller particle sizes and narrower distributions

- Environmentally cleaner and more energy efficient

- Better control over powder shape, less satellites

- Not constrained by water evaporation limits

How Does Gas Atomization Differ From Rotating Electrode Process?

- Uses gas jets rather than centrifugal forces for atomization

- Can accommodate higher melting point alloys

- Separates melting from atomization allowing better control

- Achieves higher yields of smaller particle sizes

- Lower cost atomization chamber/unit

How Does Gas Atomization Differ From Plasma Atomization?

- Does not use plasma or electric arc heating

- Operates at lower temperatures which affects microstructure

- Ability to atomize more commercial alloys and metals

- Lower capital and operating costs

- Easier scale-up to mass production volumes

So in summary, gas atomization can produce finer powders than water atomization, handle higher melting point alloys than rep, and is more commercially feasible than plasma atomization.

Metals and Alloys Atomized By The Gas Atomization Process

Titanium Alloys

- Ti-6Al-4V

- Ti 6242

- Ti 64

Applications in aerospace, medical implants, automotive etc.

Nickel Superalloys

- Inconel 718

- Inconel 625

- Rene 80

- Waspaloy

Applications in gas turbines, rocket engines, power generation.

Cobalt Superalloys

- Stellite 21

- Haynes 25

- Haynes 188

Applications include biomedical, aerospace, automotive, and tooling.

Tool & Stainless Steels

- H13 tool steel

- 420 stainless steel

- 17-4PH precipitation hardened stainless steel

Applications in injection molding, cutting tools, precision parts.

Copper Alloys

- Brass alloys

- Bronze alloys

Applications in electrical contacts, bearings, architecture.

Aluminum Alloys

- Al 6061

- Al 7075

Structural components for aerospace, automotive, and architecture.

Magnesium Alloys

- AZ91D

- ZK60A

- WE43

Applications taking advantage of light weighting.

Refractory Metals

- Tungsten

- Tantalum

- Molybdenum

Heating elements, radiation shielding, corrosion resistance.

Nearly any metal capable of being induction melted can be gas atomized into spherical powder particles with controlled characteristics.

Gas Atomized Metal Powder Characteristics

Powder Shape

- Highly spherical particle morphology

- Satellites rare or minimal

- Flowable shapes suitable for AM processing

Powder Size Distribution

- Mass median particle sizes ranging 10 – 150 microns

- Narrow particle size distributions

- Ability to classify/sieve into specific size cuts

- Quantifiable by metrics like d10, d50, d90

Powder Purity

- Oxygen pickup can be minimized with optimized design

- Other impurities based on base material cleanliness

Powder Density

- Near fully dense powders >95%

- Allows excellent packing and spreading during AM deposition

Powder Flow Characteristics

- Spherical morphology provides good powder flow

- Amenable to Hall flow and Hausner ratio testing

In summary, gas atomized powders have spherical shape, narrow size distributions, high purity and density, with flow characteristics ideal for additive manufacturing processes.

Applications and Benefits of Gas Atomized Metal Powders

Additive Manufacturing

- Provides precisely spherical powders optimal for AM

- Achieves excellent packing and spreading during deposition

- Suitable for binder jetting, DED, PBF and other AM processes

- Used across metals like stainless steels, Ni alloys, Ti alloys etc.

Metal Injection Molding (MIM)

- Binder mixing and molding amenable with fine gas atomized powders

- Gives flexibility in feedstock design and formulation

- Used for small, complex net-shape metal parts production

Thermal Spray Coatings

- Provides desired spherical morphologies

- Optimized size distributions for different spray processes

- Improved coating properties from fine gas atomized feedstocks

Hot Isostatic Pressing (HIP)

- Near net-shape HIP capsules produced via additive manufacturing

- Improved mechanical properties from uniform fine grained microstructures

Compared to other atomization methods, gas atomized powders provide the best characteristics for specialized powder-based manufacturing techniques in various metals and alloys.

Gas Atomization System Design Parameters

| Parameter | Typical Range | Comments |

|---|---|---|

| Gas Pressure | 15 – 50 Bar | Higher pressure improves atomization |

| Gas Flow Rate | 0.5 – 5 kg/s | Match to metal flow rate from nozzle |

| Melt Superheat | 100 – 500°C | Affects viscosity/surface tension |

| Nozzle Design | Close/Open Coupled | Affects pouring stream stability |

| Drop Height | 2 – 10 m | Longer height improves cooling |

| Collector Cyclone Diameter | 1 – 3 m | Larger cyclones have higher efficiency |

The key gas atomization design parameters that determine the final powder characteristics pertain to the gas jet properties interacting with the melt stream, the drop tube dimensions, and powder separation equipment sizes.

Industrial Gas Atomization Equipment Suppliers

| Company | Location | Metals Atomized | Capacity Range |

|---|---|---|---|

| AP&C | Canada | Ti, Ni, Alloys | 10 – 10,000 kg/year |

| ALD Vacuum Technologies | Germany | Ti, Ni, Superalloys | 100 – 4,000 kg/year |

| PyroGenesis | Canada | Ti, Al, Cu | 35 – 2,000 kg/batch |

| TLS Technik | Germany | Tool Steel, Ni Alloys | 50 – 500 kg/batch |

| Gasbarre Products Inc. | USA | Custom Alloys & Metals | 10 – 1,000 lbs/hour |

There are a number of companies that design and install gas atomization systems at various production volumes capable of processing different metals and alloys.

Cost Analysis of Gas Atomized Metal Powders

| Alloy | Powder Size (microns) | Cost Per Kg |

|---|---|---|

| Ti-6Al-4V | -45 +11 | $60 |

| Inconel 718 | -22 +5 | $55 |

| 316L Stainless Steel | -75 +25 | $25 |

| AlSi10Mg | 15-45 | $35 |

The cost of gas atomized powders depends significantly on the alloy composition, powder particle size distribution, order quantity, and market demand dynamics. For example, Ti-6Al-4V costs approximately $60/Kg for -45 +11 micron powder purchased in small quantities. Costs can be lower for custom gas atomization with larger order volumes.

Pros vs Cons of Gas Atomization

Advantages

- Generates highly spherical, flowable powders

- Achieves sub-50 micron particle sizes

- Narrow particle size distributions

- Clean and energy efficient process

- Environmentally friendly

- Adaptable to various alloys

- Scales to large production volumes

Limitations

- High capital equipment investment

- Requires specialized operational expertise

- Limited public data on cost analysis

- Access restricted to approved buyers

- Post-processing may be required on powders

In summary, gas atomization provides significant metallurgical and particle morphology advantages but has barriers to access from capital costs and proprietary systems.

FAQ

Q: What is the smallest particle size that can be achieved via gas atomization?

A: Using optimized nozzles and ultra-high gas velocities, gas atomization can achieve powder sizes down to 5-10 microns. However more typical range is 20-150 microns.

Q: Does gas atomization allow mixing or alloying of metals?

A: Yes, custom alloy compositions can be melted in crucibles and atomized into composite powders with tailored compositions.

Q: What affects the particle size distribution of gas atomized powders?

A: Key factors are melt stream stability, superheat levels, gas pressure and design of jet nozzles interacting with the stream.

Q: How repeatable and consistent is gas atomized powder from one batch to next?

A: Using standardized procedures and qualified equipment, consistency between batches for the same parameter settings is very high.

Q: What is the typical production capacity of an industrial gas atomizer?

A: Production capacity ranges from 10 kg/hour for smaller lab-scale units to over 1000 kg/hour for the largest production metal powder atomizers.

Q: What types of post-processing are performed on gas atomized powders?

A: Common post-processing includes de-gassing of dissolved gases, powder sieving/classification, blending, packing, and non-destructive testing.