Table of Contents

ToggleElectron beam melting (EBM) is an additive manufacturing technology used for applications like aerospace, medical, and automotive. EBM uses an electron beam as the power source to selectively melt metal powder layer-by-layer to build up fully dense parts.

Overview of electron beam melting equipment Process

Electron beam melting works by using a high power electron beam gun to selectively melt metal powder. The process takes place in a high vacuum chamber on a movable build plate. Here are some key details:

- An electron beam gun generates a focused, high-energy beam of electrons using electromagnetic coils and high voltage potential

- The electron beam is magnetically directed, similar to the cathode ray in CRT televisions

- The build plate is preheated to around half the melting point of the metal powder

- Metal powder is gravitationally fed from cassettes and raked into thin layers across the build plate

- The electron beam scans each layer, melting areas based on the CAD model

- The process is repeated layer-by-layer until the full part is built up

- Supports are built to anchor parts to the plate but are easier to remove than laser-based processes

- Common materials are titanium, nickel alloys, stainless steel, aluminum, cobalt-chrome

Benefits: Fully dense parts with fine microstructure and mechanical properties matching wrought materials. Good surface finish and dimensional accuracy.

Drawbacks: Limited number of compatible alloys, higher equipment cost than laser-based processes, slower build rates.

Applications: Aerospace components, orthopedic implants, automotive parts, conformal cooling channels, metal lattices.

Metal Powder Feedstocks Used in Electron Beam Melting

The metal powder feedstock plays a critical role in component quality and material properties. Common alloys used include:

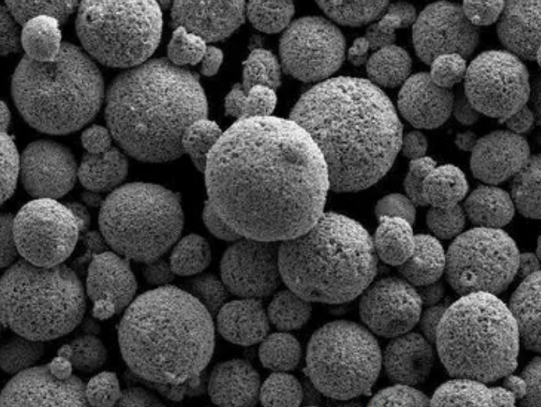

Fine powders in the optimal size distribution ensures smooth powder bed stability and uniform layers for higher part quality. Plasma atomization and gas atomization produce spherical powders desirable for packing during layer deposition.

Suppliers: AP&C, Carpenter Additive, Sandvik Osprey, Praxair, LPW Technology

Electron Beam Melting Process Parameters

EBM machines utilize proprietary software for generating scanning strategies and optimizing build parameters. Some key parameters include:

The plate is heated to high temperatures reduce brittleness, relieve stresses, and avoid large thermal gradients. The beam speed and hatch spacing determine how much energy is put into each unit area of powder. Beam focus and layer thickness also influence local melting conditions. Different scanning approaches impact residual stresses and microstructures.

Advantages of Electron Beam Additive Manufacturing

Some of the advantages of EBM include:

| Feature | Benefit |

|---|---|

| High beam power density | Rapid melting and solidification promoting fine microstructures |

| Vacuum environment | Clean material processing minimizes oxide inclusions and voids |

| High temperature preheating | Reduces residual stresses and deformation |

| Full melting | Achieves over 99.9% density similar to wrought materials |

| Support anchors | Easier removal compared to delicate lattice supports in lasers |

| Multiple parts per build | Efficient production of small components |

The highly focused electron beam allows very rapid, precise deposition of energy into the powder bed. The vacuum prevents contamination while the preheating provides desirable material properties. This facilitates full density across complex parts.

Limitations and Comparisons to Other Processes

| Limitations | Comparison to Lasers |

|---|---|

| Higher equipment cost | Electron beam systems over $750,000 vs $300,000 for lasers |

| Slower build rates | Up to 110 cm3/hour for EBM vs 150 cm3/hour for lasers |

| Limited alloys | 20+ commercial alloys for lasers vs 10 for EBM |

| Part size | 1500 x 1500 x 1200 mm max for EBM vs 1000 mm cubes for lasers |

| Surface finish | EBM rougher at 25 microns vs 12 microns for DMLS |

| Heat affected zones | Smaller in EBM due to rapid solidification |

The focused electron beam can achieve smaller melt pools and scan faster than lasers to reduce defects. But laser-based DMLS and SLM boast faster builds and better surface finishes currently. The range of compatible alloys is also expanding much quicker for laser powder bed fusion processes through better powder spreading and recoating mechanisms.

Applications of Electron Beam Melting Parts

Some of the industries using EBM include:

| Industry | Components |

|---|---|

| Aerospace | Turbine blades, rocket parts, UAV components |

| Medical | Orthopedic implants like hips, knees, trauma devices |

| Automotive | Conformal cooling lines, prototypes |

| Tooling | Injection molds with conformal channels |

| Energy | Valves, pumps for oil and gas environments |

Due to the vacuum processing, EBM is uniquely suited for reactive metals like titanium and tantalum. It has been used extensively to manufacture TI-6Al-4V aerospace components with complex internal geometries. In the medical field, EBM cobalt chrome and stainless steel see usage for patient-specific implants with bone-like porous structures.

The automotive, energy, and tools industries are increasingly utilizing DMLS and EBM for lightweight prototypes, jigs, and fixtures with conformal cooling designs. This improves turnaround times and heat management.

Suppliers of Electron Beam Melting Equipment

Here are some of the major EBM system manufacturers:

Arcam was founded in 1997 and is now part of GE Additive. They focused first on the medical implant production but now also targets aerospace and automotive. Sciaky offers large-scale industrial EBM for titanium and nickel alloys up to 10 feet long. Additive Industries, Trumpf, and General Atomics also have EBM metal 3D printers under development for advanced applications.

Besides purchasing full EBM setups, customers also have access to GE’s extensive service bureau capacity around the world or can work with local specialty manufacturers offering metal AM contracting.

Future Outlook for Electron Beam Additive Manufacturing

The prospects for electron beam melting look promising across industries desiring high-performance metal components with complex internal geomestructures:

- Expanding range of alloy options – stainless steel, aluminum, copper

- Larger build envelopes for printing whole fuel assemblies or aircraft doors

- Increased build rates through multi-beam systems

- Hybrid manufacturing by combining EBM and computerized CNC machining

- Design-specific parameters for enhanced material properties

- Closed-loop control for in-situ monitoring and correction

- Specialized post-processing to improve side surface roughness

- Simulation tools to model residual stress and distortion effects

By overcoming limitations in speed, size constraints, and alloy availability while moving down the cost curve, EBM usage could grow from a $400 million market currently to $5-10 billion by 2030. Aerospace, medical, automotive, and energy sectors are expected to drive this meteoric rise over the next decade.

FAQ

Here are answers to some frequently asked questions about electron beam additive manufacturing:

What materials can you process with EBM?

The most common alloys are Ti-6Al-4V, Ti-6Al-4V ELI, and CoCr, but also nickel alloys like Inconel 718, aluminum alloys, tool steel, stainless steel 316L. Powder feedstock composition and quality must meet aerospace and biomedical specifications.

How accurate is EBM?

Dimensional accuracy reaches up to ±0.2% with tolerances down to ±100 microns generally. But achieving tight statistical distributions often requires hot isostatic pressing and machining to improve surface finish.

What industries use this technology?

Aerospace, defense, space, medical and dental, automotive racing, oil and gas industries primarily use EBM today. The high beam energy coupled with high chamber temperatures facilitates reactive material processing and superior material properties.

How does EBM compare with selective laser melting (SLM)?

EBM produces fully dense Ti-6Al-4V parts with superior tensile strength and elongation compared to SLM. It also handles reactive materials better with lower contamination issues. But SLM currently enables higher resolutions, finer surface finishes down to 12 microns, and faster build rates.

What post-processing methods are used on EBM parts?

Support removal via abrasive blasting, cut-off wheels, or wire EDM, followed by machining, grinding or polishing to meet dimensional and surface roughness requirements per application. Hot isostatic pressing (HIP) helps to eliminate internal voids and relieve stresses.

What types of internal channels and geoemetries can be produced using EBM?

Straight cooling channels at shallow angles, thin wall structures, lattices, and mesh geometries are common. Complex freeform shapes like trabecular bone structures are also possible. Feature sizes down to 0.4 mm have been demonstrated but scale with layer thickness.

Conclusion

In summary, electron beam melting provides substantial advantages over traditional manufacturing techniques for complex, high-performance metal components across aerospace, medical, automotive, and defense sectors. As the capabilities continue to improve around larger build volumes, multi-beam systems, and specialized post-processing, wider adoption is expected in the transportation, energy, and industrial production industries over the next decade.