Table of Contents

Toggle3d printing titanium powder is a strong, lightweight, and corrosion-resistant metal that is ideal for 3D printing complex and durable parts for aerospace, automotive, medical, and other advanced applications. This article provides a comprehensive overview of titanium powder metallurgy, properties, applications, and suppliers for additive manufacturing with titanium.

Overview of 3d printing titanium powder

Titanium is a desirable material for 3D printing due to its high strength-to-weight ratio, fatigue and fracture resistance, and biocompatibility. Titanium powders allow parts to be printed by powder bed fusion processes with fine features and complex geometries.

Titanium grades: Commonly used titanium alloys for AM include Ti-6Al-4V (Ti64), Ti64 ELI, commercially pure (CP) Ti grade 2, and Ti 6242.

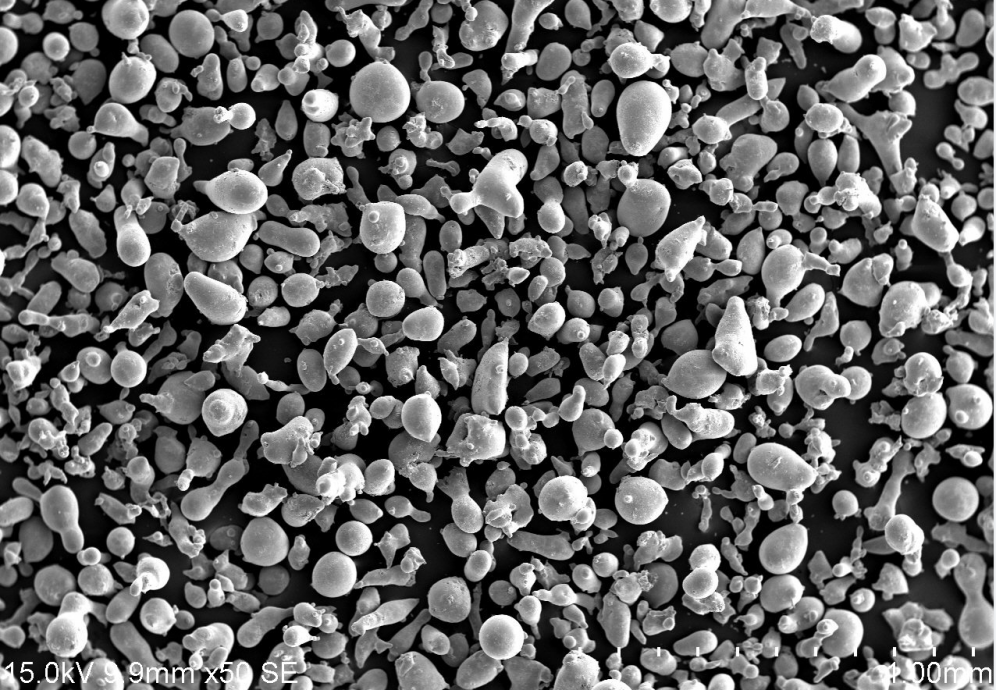

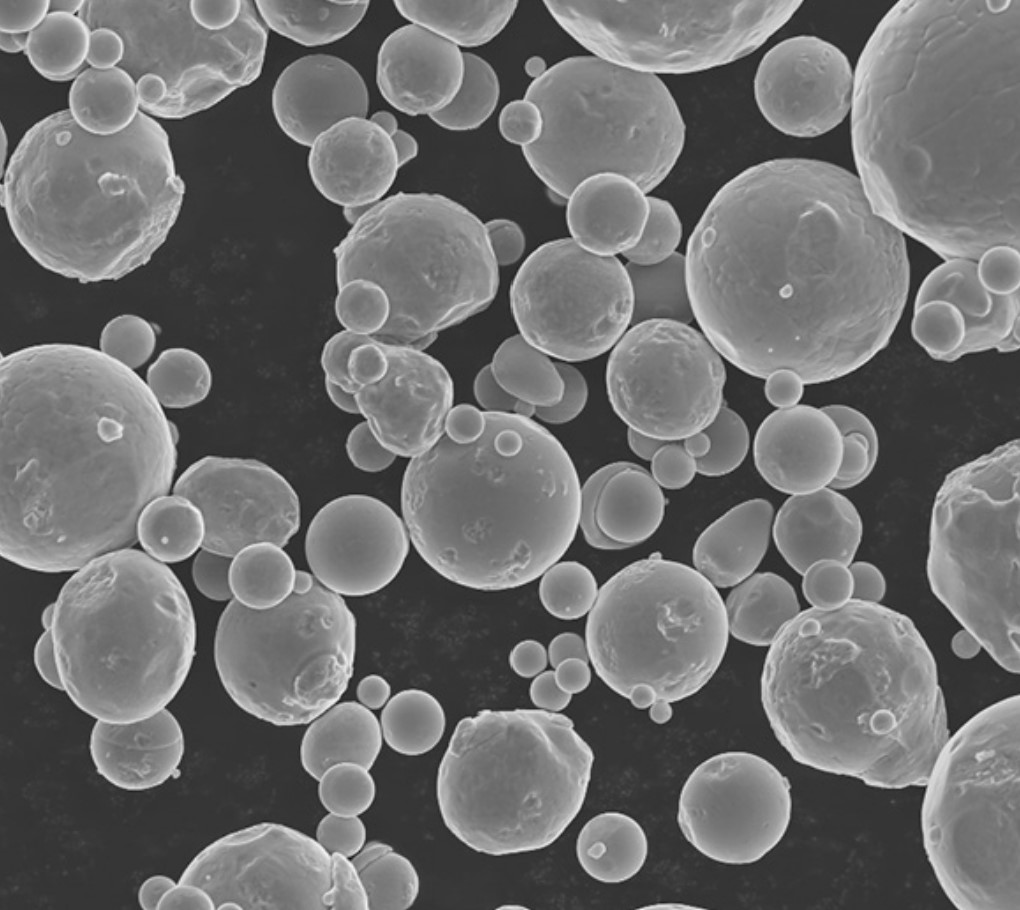

Powder production: Titanium powder is produced by gas atomization where molten titanium is atomized by an inert gas jet into fine spherical particles with tight size distribution. Plasma rotating electrode process (PREP) is also used.

Powder sizes: Typical powder sizes range from 15-45 microns. Finer powders around 15 microns allow better resolution while coarser 45 micron powder allows higher build rates.

Flowability and reuse: Spherical morphology and controlled size distribution impart good flowability. Titanium powder can usually be reused up to 10-20 times if handled properly.

Safety: Titanium powder is highly flammable and reactive with air due to its pyrophoric nature. Proper handling in an inert atmosphere is critical.

Composition and Microstructure

Titanium powder composition, microstructure, phases present, and defects like porosity determine the final properties of printed parts.

Elemental composition

| Alloy | Titanium | Aluminum | Vanadium | Iron | Oxygen | Nitrogen | Hydrogen |

|---|---|---|---|---|---|---|---|

| Ti-6Al-4V | Balance | 5.5-6.5% | 3.5-4.5% | <0.3% | <0.2% | <0.05% | <0.015% |

| Ti-6Al-2Sn-4Zr-6Mo | Balance | 5.5-6.5% | – | – | – | – | – |

| CP Grade 2 Ti | 99.2% min | – | – | 0.3% max | 0.25% max | 0.03% max | 0.015% max |

Phases: Titanium alloys contain mixture of α hexagonal close packed and β body centered cubic phases. Cooling rates in AM can generate non-equilibrium phases.

Defects: Lack of fusion, porosity, microcracks can occur and degrade mechanical properties. Hot isostatic pressing (HIP) helps reduce defects and improve consistency.

Grain structure: Columnar prior-β grains along build direction are seen in AM titanium alloys due to rapid solidification and epitaxial growth. The widths of columnar grains influence strength.

Surface roughness: Powder bed fusion processes lead to semi-smooth as-printed surfaces due to partially melted powder particles. Additional finishing is often required.

Key Properties

The properties of printed titanium parts are influenced by composition, porosity, surface roughness, build orientation, heat treatment, and testing direction.

Physical properties

| Property | Ti-6Al-4V | CP Grade 2 Ti |

|---|---|---|

| Density (g/cc) | 4.42 | 4.51 |

| Melting point (°C) | 1604-1660 | 1668 |

Mechanical properties

| Property | As-printed | Hot isostatic pressed (HIP) | Wrought mill-annealed |

|---|---|---|---|

| Tensile strength (MPa) | 900-1300 | 950-1150 | 860-965 |

| Yield strength (MPa) | 800-1100 | 825-900 | 790-870 |

| Elongation at break (%) | 5-15 | 8-20 | 15-25 |

| Hardness (HRC) | 32-44 | 32-36 | 31-34 |

Advantages

- High strength-to-weight ratio

- Retains strength at elevated temperatures

- Resistant to fatigue, wear, and corrosion

- Bioinert – suitable for medical implants

- Can withstand sterilization treatments

Limitations

- Expensive material and AM processing

- Reactive and flammable powder

- Anisotropic properties

- Lower ductility than wrought forms

Applications of Additively Manufactured Titanium Parts

3D printing expands uses for titanium into lighter, stronger, and higher-performing components across industries.

Aerospace: Turbine blades, airframe and engine structures, antennas, heat exchangers

Automotive: Connecting rods, valves, turbocharger wheels, drivetrain components

Medical and dental: Orthopedic implants, prosthetics, surgical instruments, patient-matched devices

Oil and gas: Corrosion-resistant pipes, valves, wellhead components, separators

Consumer goods: Sporting equipment like bicycle frames, golf club heads, eyeglass frames

Tooling: Lightweight conformal cooling channels integrated into metal injection molds, jigs, fixtures

Popular 3d printing titanium powder for AM

| Alloy | Applications | Printability | Surface Finish | Mechanical Properties |

|---|---|---|---|---|

| Ti-6Al-4V ELI | Aerospace components, biomedical implants | Excellent | Moderate | High strength, hardness, fatigue life |

| Ti-6Al-4V | Structural aerospace parts, automotive | Very good | Moderate | Strength, fracture toughness |

| Ti 6242 | High-temperature components | Good | Poor | Strength at 300°C, creep resistance |

| CP Grade 2 Titanium | Medical implants, chemical plants | Moderate | Very good | Ductility, corrosion resistance |

Specifications and Standards

Stringent quality requirements are enforced for titanium powder and printed parts per aerospace and medical standards.

Powder specifications

| Parameter | Requirement | Test Method |

|---|---|---|

| Particle size | 15-45 μm | Laser diffraction |

| Apparent density | ≥ 2.7 g/cc | Hall flowmeter |

| Tap density | ≥ 3.2 g/cc | Tap density tester |

| Flow rate | 15-25 s/50g | Hall flowmeter |

| Chemical composition | Certificate of analysis | GDMS, ICP-MS |

Part qualification standards

| Standard | Details |

|---|---|

| ASTM F3001 | Standard for AM titanium parts |

| ASTM F2924 | Titanium alloy Ti-6Al-4V ELI |

| ASTM F3184 | Feedstock titanium alloy powder |

| AMS7009 | Aerospace material specification |

| ISO 13485 | Medical devices – Quality management |

Design Principles for Titanium AM

Proper component design is crucial to harness benefits of additive manufacturing with titanium.

- Minimize overhangs to avoid support structures

- Orient parts to enable easier powder removal

- Allow for post-processing like HIP and machining

- Include built-in channels for conformal cooling

- Consolidate assemblies into single titanium parts

- Reinforce high stress regions with lattices

- Optimize shapes for weight reduction via topology optimization

Suppliers of 3d printing titanium powder

| Supplier | Grades Offered | Powder Sizes | Additional Services |

|---|---|---|---|

| AP&C | Ti-6Al-4V, Ti-6Al-4V ELI, Ti64, CP-Ti grades 1-4 | 15-45 μm | Analysis, testing, sieving, blending, storage |

| Carpenter Additive | Ti-6Al-4V, Ti-6Al-2Sn-4Zr-6Mo | 15-45 μm | Custom alloys, parameter development |

| LPW Technology | Ti-6Al-4V ELI, Ti-6Al-4V, CP-Ti grade 2 | 15-45 μm | Material testing, powder reuse analysis |

| Praxair | Ti-6Al-4V, Ti-6Al-4V ELI | 15-100 μm | Sieving, blending, storage |

| Sandvik | Osprey titanium alloys | 15-45 μm | Powder lifecycle management |

Cost: ~$500-$1000 per kg but depends on order volume, grade, size distribution, gas atomization method, additional handling, and testing requirements.

FAQs

Q: What methods can be used to 3D print titanium parts?

A: Titanium is primarily printed by powder bed fusion using selective laser melting (SLM) and electron beam melting (EBM). Wire-based methods like laser metal deposition (LMD) and weld-based directed energy deposition (DED) are also possible but less common.

Q: Does titanium powder for AM require special storage or handling?

A: Yes, titanium reacts readily with air so the powder must be stored and processed under inert atmosphere using argon or nitrogen gas. Flammable environments and ignition sources must be avoided. Operators should wear protective equipment when handling titanium powder.

Q: What causes porosity issues in titanium AM parts?

A: High cooling rates lead to gas entrapment causing lack of fusion defects. Optimization of parameters like power, speed, hatch spacing, focus offset and powder layer density are required to minimize porosity. Hot isostatic pressing (HIP) can also help densify parts after initial printing.

Q: Why is it hard to achieve smooth titanium surfaces directly after AM processing?

A: Partially melted titanium powder can adhere to surfaces causing a rough finish. Tumbling, sandblasting, milling, grinding and polishing are secondary operations used to smooth titanium printed parts. Chemically or electrochemically finishing processes are also used.

Q: Can you 3D print commercially pure titanium?

A: Yes, grades 1 through 4 unalloyed CP titanium powder meeting ASTM standards like B348 for composition and particle size distribution can be used to print pure titanium components for applications needing high ductility like bone implants and chemical plants.