Table of Contents

ToggleIntroduction

In the world of advanced materials, titanium alloys have garnered significant attention due to their exceptional properties and wide range of applications. Among these alloys, TC11 Titanium Alloy stands out as a versatile and high-performance material. This article will explore the various aspects of TC11 Titanium Alloy, including its properties, applications, advantages, challenges, and future developments.

What is TC11 Titanium Alloy?

TC11 Titanium Alloy is a type of titanium alloy that belongs to the class of alpha-beta alloys. It is composed primarily of titanium, along with small percentages of other elements such as aluminum and vanadium. The addition of these alloying elements enhances the overall performance of titanium, making TC11 Titanium Alloy an ideal choice for various industries.

Properties of TC11 Titanium Alloy

Strength and Durability

TC11 Titanium Alloy exhibits excellent strength and durability, making it suitable for applications where high mechanical properties are required. It has a high strength-to-weight ratio, surpassing that of many other metals. This property allows for the design of lightweight structures without compromising on strength, providing significant advantages in industries such as aerospace and automotive.

Corrosion Resistance

One of the most notable properties of TC11 Titanium Alloy is its exceptional corrosion resistance. It has a natural oxide layer that forms on its surface, protecting it from corrosive environments. This characteristic makes TC11 Titanium Alloy highly sought after in applications where exposure to harsh conditions or corrosive substances is common, such as marine environments or chemical processing plants.

Lightweight Nature

TC11 Titanium Alloy is renowned for its lightweight nature. It has a low density compared to other structural metals, such as steel or aluminum. This attribute is particularly advantageous in industries that prioritize weight reduction, such as aerospace and sports equipment manufacturing. The use of TC11 Titanium Alloy enables the creation of lightweight components without sacrificing strength or structural integrity.

High Temperature Resistance

Another remarkable property of TC11 Titanium Alloy is its ability to withstand high temperatures. It exhibits excellent heat resistance, making it suitable for applications that involve elevated temperatures, such as gas turbines or heat exchangers. TC11 Titanium Alloy can maintain its mechanical properties even at extreme temperatures, which further expands its potential applications in various industries.

Applications of TC11 Titanium Alloy

Aerospace Industry

The aerospace industry extensively utilizes TC11 Titanium Alloy due to its exceptional properties. It is used in the construction of aircraft components, such as airframes, landing gear, and engine parts. The lightweight nature, high strength, and corrosion resistance of TC11 Titanium Alloy make it a preferred choice for reducing fuel consumption and enhancing overall aircraft performance.

Automotive Industry

In the automotive industry, TC11 Titanium Alloy finds applications in exhaust systems, suspension components, and engine parts. The lightweight nature of the alloy contributes to fuel efficiency and improved vehicle handling. Additionally, the corrosion resistance of TC11 Titanium Alloy ensures the longevity of automotive components, particularly in regions with harsh weather conditions.

Medical Field

TC11 Titanium Alloy is widely used in the medical field, particularly for orthopedic implants and prosthetic devices. Its biocompatibility, corrosion resistance, and strength make it an excellent choice for implants that require long-term durability within the human body. TC11 Titanium Alloy implants offer improved patient outcomes, as they reduce the risk of rejection and provide better compatibility with bone tissues.

Sports Equipment

The sports equipment industry benefits from TC11 Titanium Alloy’s properties, particularly its lightweight nature and strength. It is commonly used in the manufacturing of bicycle frames, golf clubs, tennis rackets, and other sporting gear. The alloy’s high strength-to-weight ratio allows athletes to optimize their performance by utilizing equipment that is both durable and lightweight.

Other Industrial Applications

TC11 Titanium Alloy finds applications in various other industries as well. It is used in chemical processing equipment, power generation systems, desalination plants, and marine structures. The alloy’s corrosion resistance and high temperature stability make it a reliable choice for these demanding industrial environments.

Advantages of Using TC11 Titanium Alloy

Enhanced Performance

The utilization of TC11 Titanium Alloy in various applications provides enhanced performance compared to traditional materials. The alloy’s combination of strength, durability, and lightweight nature contributes to improved efficiency, fuel economy, and overall product performance. This advantage is particularly crucial in industries where weight reduction and high performance are key factors.

Cost Efficiency

While the initial costs of TC11 Titanium Alloy may be higher than those of conventional materials, its long-term cost efficiency is often superior. The alloy’s exceptional durability and corrosion resistance result in reduced maintenance and replacement costs. Moreover, the lightweight nature of TC11 Titanium Alloy contributes to fuel savings, making it a cost-effective choice for industries that prioritize efficiency.

Environmental Friendliness

TC11 Titanium Alloy offers environmental benefits due to its lightweight nature and extended product lifespan. The reduced weight of components leads to lower fuel consumption and emissions, contributing to a greener environment. Additionally, the corrosion resistance of TC11 Titanium Alloy ensures that components have a longer lifespan, reducing the overall environmental impact associated with frequent replacements.

Challenges and Limitations of TC11 Titanium Alloy

Manufacturing Complexity

The manufacturing of TC11 Titanium Alloy components can be more complex compared to traditional materials. Specialized techniques and equipment are required to shape, join, and finish the alloy. This complexity may increase production costs and require skilled labor. However, advancements in manufacturing technologies continue to address these challenges, making TC11 Titanium Alloy more accessible.

High Initial Costs

TC11 Titanium Alloy may have higher initial costs compared to conventional materials. The extraction and processing of titanium, as well as the addition of alloying elements, contribute to the higher price tag. However, the long-term benefits and cost-efficiency of TC11 Titanium Alloy often outweigh the initial investment, especially in industries where its exceptional properties are critical.

Limited Availability

The availability of TC11 Titanium Alloy may be limited compared to more widely used metals such as steel or aluminum. The extraction and refining processes for titanium are specialized and require specific resources. However, as demand for titanium alloys increases and technologies advance, the availability of TC11 Titanium Alloy is expected to improve over time.

Future Developments and Innovations

The future of TC11 Titanium Alloy holds exciting possibilities. Ongoing research and development efforts aim to further enhance the properties and capabilities of TC11 Titanium Alloy. Some areas of focus include:

- Alloy Optimization: Researchers are working on refining the composition of TC11 Titanium Alloy to maximize its strength, durability, and other desirable properties. By fine-tuning the alloy’s composition and microstructure, they aim to create even more advanced versions of TC11 Titanium Alloy with superior performance characteristics.

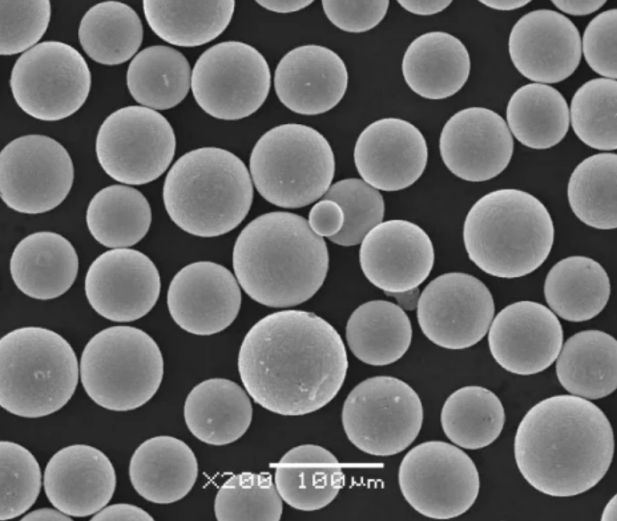

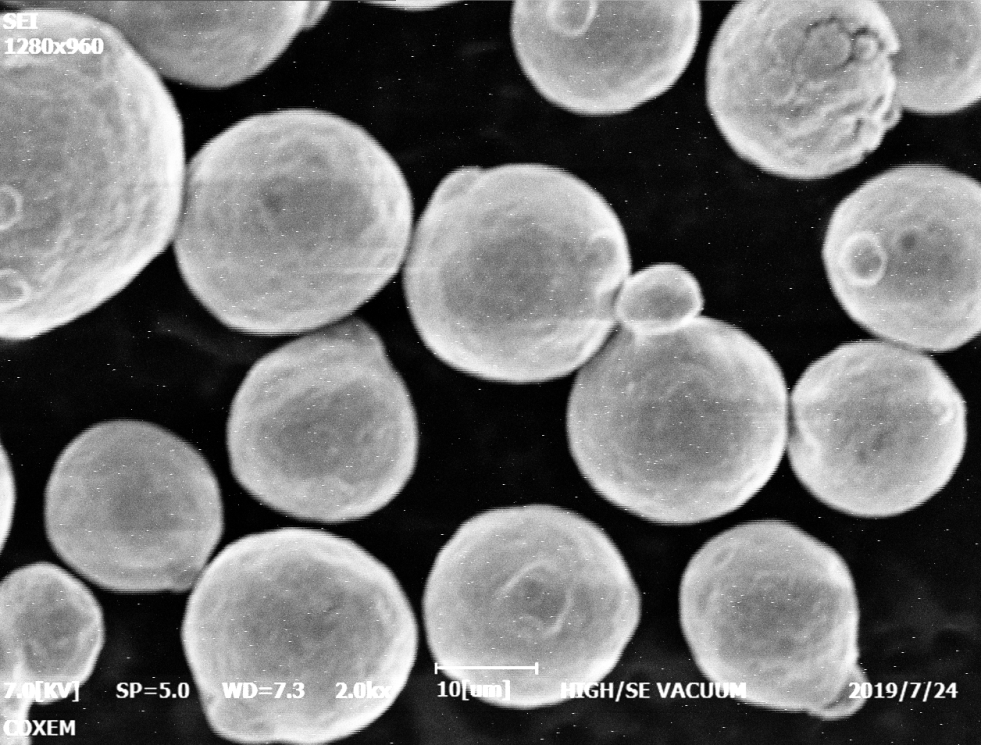

- Additive Manufacturing: The emergence of additive manufacturing, also known as 3D printing, has opened new avenues for titanium alloy production. Scientists are exploring the use of additive manufacturing techniques to fabricate complex components with optimized designs and reduced material waste. This advancement has the potential to revolutionize the production process of TC11 Titanium Alloy and expand its applications further.

- Surface Modifications: Researchers are investigating surface modification techniques to enhance the properties of TC11 Titanium Alloy even further. By applying specialized coatings or surface treatments, they aim to improve wear resistance, reduce friction, and enhance the alloy’s biocompatibility for medical applications. These surface modifications can unlock new possibilities for TC11 Titanium Alloy in various industries.

- Recycling and Sustainability: As environmental concerns become more prominent, efforts are being made to improve the sustainability of titanium alloys, including TC11. Recycling technologies are being developed to recover and reuse titanium alloys, reducing the reliance on primary production and minimizing the environmental impact. These initiatives aim to create a more sustainable supply chain for TC11 Titanium Alloy and contribute to a circular economy.

- Advanced Joining Techniques: Joining titanium alloys, including TC11, can be challenging due to their unique properties. Researchers are exploring innovative joining techniques such as friction stir welding, laser welding, and electron beam welding to overcome these challenges. These advancements in joining technologies will enable the creation of more complex and reliable TC11 Titanium Alloy structures.

- Hybrid Material Combinations: The combination of TC11 Titanium Alloy with other advanced materials, such as composites or ceramics, is being investigated to create hybrid materials with superior properties. These combinations can leverage the strengths of each material, resulting in enhanced performance, weight reduction, and increased functionality for specific applications.

In summary, the future of TC11 Titanium Alloy looks promising with ongoing research and development activities. These efforts aim to optimize its properties, explore new manufacturing techniques, enhance sustainability, and unlock new applications for this versatile alloy.

Conclusion

TC11 Titanium Alloy stands out as a remarkable material in the world of advanced alloys. Its exceptional properties, including strength, durability, corrosion resistance, and lightweight nature, make it a preferred choice across various industries. From aerospace and automotive to medical and sports equipment, TC11 Titanium Alloy finds applications where high performance and reliability are paramount. Despite the challenges of manufacturing complexity, initial costs, and limited availability, the long-term benefits and cost efficiency of TC11 Titanium Alloy make it a compelling choice for many applications. Furthermore, ongoing research and development efforts continue to push the boundaries of TC11 Titanium Alloy, paving the way for future innovations and expanded possibilities in diverse industries.

FAQs

1. Is TC11 Titanium Alloy stronger than steel?

Yes, TC11 Titanium Alloy has a higher strength-to-weight ratio than steel. It offers comparable strength while being significantly lighter in weight.

2. Can TC11 Titanium Alloy be used in medical implants?

Yes, TC11 Titanium Alloy is widely used in the medical field for orthopedic implants and prosthetic devices. Its biocompatibility, corrosion resistance, and strength make it an excellent choice for long-term implant durability.

3. Is TC11 Titanium Alloy expensive?

TC11 Titanium Alloy may have higher initial costs compared to conventional materials. However, its long-term cost efficiency, durability, and performance benefits often outweigh the initial investment.

4. Can TC11 Titanium Alloy be recycled?

Yes, TC11 Titanium Alloy can be recycled. Recycling technologies are being developed to recover and reuse titanium alloys, contributing to a more sustainable supply chain.

5. Are there any alternatives to TC11 Titanium Alloy?

There are other titanium alloys available, each with its own unique properties and applications. Some alternatives to TC11 Titanium Alloy include TC4 Titanium Alloy and Ti-6Al-4V Titanium Alloy. The choice of alloy depends on specific requirements and industry applications.