Table of Contents

ToggleIntroduction

In the world of modern materials engineering, titanium aluminium powder stands out as a revolutionary alloy that has transformed various industries. This unique combination of titanium and aluminium has garnered immense attention due to its exceptional properties and diverse applications. In this article, we will delve into the captivating world of titanium aluminium powder, exploring its uses, production methods, safety considerations, market trends, environmental impact, and future prospects.

What is Titanium Aluminium Powder?

Titanium aluminium powder is a finely blended alloy consisting of titanium (Ti) and aluminium (Al). It exhibits a perfect synergy of the remarkable properties of both elements, resulting in a material that surpasses conventional metals in several aspects. The alloy’s chemical composition and microstructure contribute to its exceptional performance, making it highly sought after in various sectors.

Uses of Titanium Aluminium Powder

Additive Manufacturing

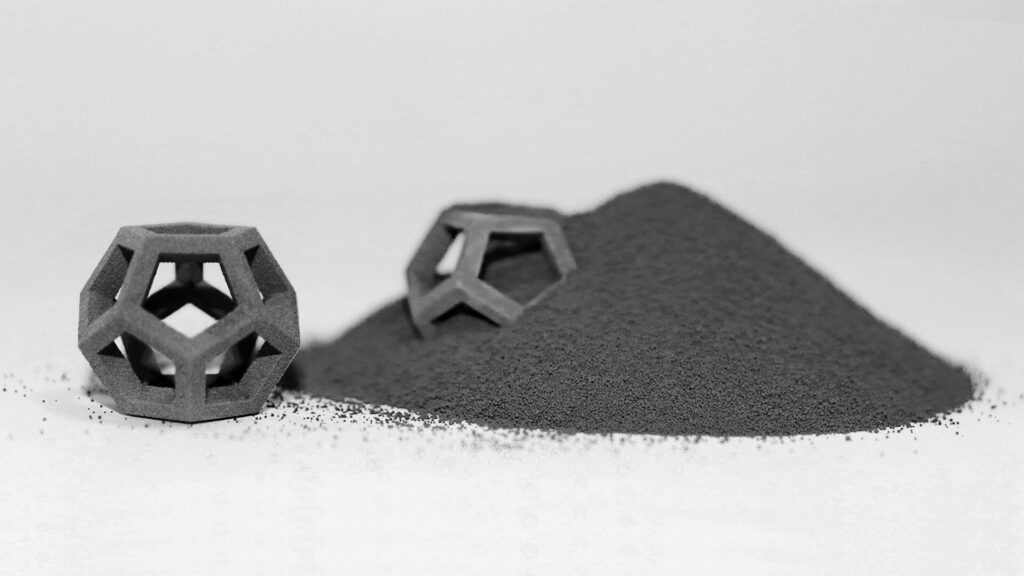

One of the most exciting applications of titanium aluminium powder is in the field of additive manufacturing, commonly known as 3D printing. The alloy’s unique properties make it an ideal choice for creating lightweight yet robust components used in aerospace, automotive, and medical industries.

Aerospace Industry

The aerospace sector relies heavily on materials that offer exceptional strength-to-weight ratios. Titanium aluminium powder has emerged as a game-changer in this industry, enabling the construction of aircraft components that are not only durable but also significantly lighter, contributing to fuel efficiency.

Pyrotechnics

In the world of fireworks and pyrotechnics, the brilliance and color intensity of the displays largely depend on the materials used. Titanium aluminium powder’s high combustion temperature and ability to produce bright sparks have made it a key ingredient in creating dazzling firework displays.

Coatings and Pigments

The powder’s unique properties extend to the world of coatings and pigments, where it offers enhanced corrosion resistance and durability. Titanium aluminium powder finds use in protective coatings for various materials, such as metals and plastics.

Chemical Reactions

The alloy’s reactivity makes it an excellent catalyst in chemical reactions. Its inclusion in chemical processes enhances reaction rates and opens up new avenues in industrial applications.

Properties of Titanium Aluminium Powder

High Strength-to-Weight Ratio

The most prominent feature of titanium aluminium powder is its impressive strength-to-weight ratio. This property makes it highly desirable for applications where lightweight yet sturdy materials are required.

Corrosion Resistance

Titanium aluminium powder exhibits exceptional resistance to corrosion, even in harsh environments. This attribute makes it an excellent choice for applications where exposure to corrosive substances is unavoidable.

Thermal Stability

The alloy’s thermal stability allows it to withstand high temperatures without significant degradation. This characteristic is especially crucial in aerospace and automotive applications, where components are subjected to extreme heat.

Conductivity

In certain applications, electrical and thermal conductivity play pivotal roles. Titanium aluminium powder’s conductivity properties open up opportunities in the electronics and energy sectors.

Combustibility

The alloy’s combustibility is skillfully harnessed in pyrotechnics, enabling spectacular firework displays and other entertainment events.

Production of Titanium Aluminium Powder

Mechanical Alloying

Mechanical alloying is a popular method for producing titanium aluminium powders. This process involves repeated welding, fracturing, and rewelding of powders in a high-energy ball mill.

Chemical Reactions

In some cases, titanium aluminium powders can be obtained through exothermic reactions between titanium and aluminium compounds.

Atomization

Atomization involves converting molten alloy into fine droplets using gas or liquid jets. These droplets solidify into powder particles as they cool down, resulting in titanium aluminium powder.

Safety Considerations

Handling and Storage

Like any other powder, titanium aluminium powder requires proper handling and storage to avoid accidents and maintain its properties.

Fire Hazards

Due to its combustibility, the powder must be handled with care to prevent fire hazards, especially in industrial settings.

Toxicity

While the alloy itself is not toxic, precautions must be taken during its production and handling to ensure the safety of workers and the environment.

Market Trends and Applications

The market for titanium aluminium powder continues to grow rapidly as industries discover new applications and benefits of this extraordinary alloy. From aerospace and automotive to biomedical and entertainment, its versatility is captivating various sectors, leading to a surge in demand.

Environmental Impact

Understanding the environmental impact of materials is crucial in today’s world. We explore how the production and use of titanium aluminium powder affect the environment and potential eco-friendly approaches.

Future Prospects

As technology advances and research into material science deepens, the future prospects of titanium aluminium powder appear even more promising. This section delves into the potential advancements and breakthroughs that await this miraculous alloy.

Conclusion

Titanium aluminium powder stands as a testament to human ingenuity and the power of material engineering. Its exceptional properties and applications have transformed industries and opened up new possibilities. As research progresses, we can expect this alloy to continue shaping the future of technology and innovation.

FAQs

Is titanium aluminium powder stronger than steel?

We explore how the strength-to-weight ratio of titanium aluminium powder surpasses that of steel, making it a superior choice in specific applications.

Can titanium aluminium powder be used in medical implants?

Discover how this alloy’s biocompatibility and strength have made it a potential candidate for medical implants.

Are there any eco-friendly production methods for titanium aluminium powder?

We discuss ongoing research into more sustainable production methods to reduce the environmental impact of this alloy.

How is titanium aluminium powder different from other titanium alloys?

Learn about the distinctive features that set titanium aluminium powder apart from other titanium-based alloys.

What safety precautions should be taken when working with titanium aluminium powder?

We provide essential safety guidelines for handling, storing, and using this powder in various applications.