Table of Contents

ToggleMetal alloy powders are finely divided metallic materials produced by atomizing and condensing molten alloys. They exhibit unique properties and are used across various industries in powder metallurgy, additive manufacturing, and thermal spray applications. This comprehensive guide covers everything you need to know about metal alloy powders.

Overview of Metal Alloy Powders

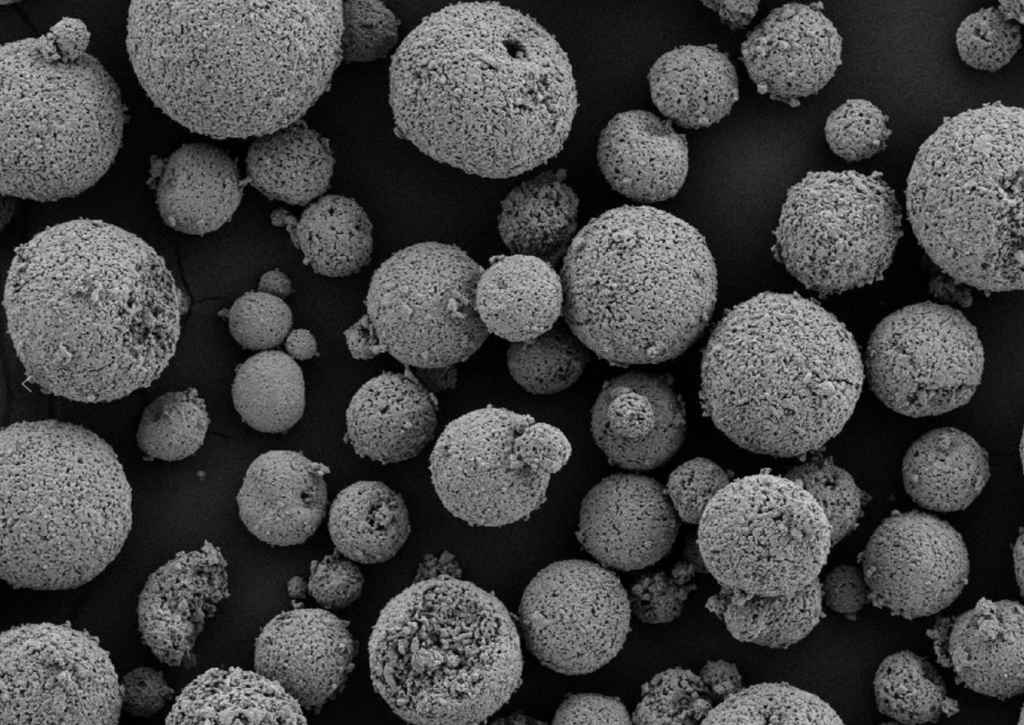

Metal alloy powders are made by melting an alloy composition and then turning the molten metal into fine droplets using gas or water atomization. The droplets rapidly solidify into powder particles with a spherical or irregular morphology.

Key properties of metal alloy powders:

- High purity, homogeneity, and consistent composition

- Controlled particle size distribution

- Spherical particle shape with high flowability

- Modifiable surface chemistry

- Ability to manufacture high-performance parts

Metal alloy powders open up design flexibility and part consolidation opportunities over bulk alloys. They are used in various applications:

Applications of Metal Alloy Powders

| Application | Description |

|---|---|

| Powder metallurgy | Compacting powder into final parts |

| Metal injection molding | Mixing powder with binder and injection molding |

| Additive manufacturing | 3D printing of complex, lightweight parts |

| Thermal spraying | Depositing coatings for wear/corrosion resistance |

| Brazing | Filler material for joining components |

| Electronics | Forming conductors, resistors, inductors |

The unique properties of metal alloy powders make them suitable for specialized applications across industries like aerospace, automotive, medical, energy, and more.

Types of Metal Alloy Powders

Many alloy systems are commercially available in powder form. The most common metal alloy powder types include:

Common Metal Alloy Powder Types

| Alloy Type | Key Alloys | Applications |

|---|---|---|

| Nickel alloys | Inconel, Monel, Hastelloy | Aerospace, chemical plants |

| Cobalt alloys | Stellite, Haynes | Cutting tools, biomedical |

| Tool steels | H13, M2, M4 | Cutting tools, molds |

| Stainless steels | 316L, 17-4PH, 420 | Implants, marine hardware |

| Titanium alloys | Ti-6Al-4V, Ti-6Al-7Nb | Aerospace, medical |

| Aluminum alloys | 6061, 7075, 2024 | Automotive, aerospace |

| Copper alloys | Brass, bronze | Electrical contacts, bearings |

Nickel, cobalt, and titanium alloys are common in high-temperature applications. Stainless steels resist corrosion. Tool steels and copper alloys provide hardness and wear resistance. Lightweight aluminum alloys are used for weight-critical components.

Composition of Metal Alloy Powders

The composition of metal alloy powders can be customized to achieve required properties by selecting appropriate alloying elements. Some typical compositions are:

Typical Compositions of Metal Alloy Powders

| Alloy | Key Alloying Elements |

|---|---|

| Inconel 718 | Ni, Cr, Fe, Nb, Mo, Ti, Al |

| 420 stainless steel | Fe, Cr, Mn, Si, C |

| 6061 aluminum | Al, Mg, Si, Cu, Cr |

| H13 tool steel | Fe, Cr, Mo, V, Si, Mn |

| Bronze | Cu, Sn |

Small amounts of carbon, nitrogen, boron, and other elements can be added to tailor specific characteristics like strength, hardness, ductility, corrosion resistance, or high-temperature performance.

Precise control over composition ensures consistent, repeatable performance of metal parts made from alloy powders.

Properties of Metal Alloy Powders

Key properties of metal alloy powders that determine their performance:

Properties of Metal Alloy Powders

| Property | Typical Values | Significance |

|---|---|---|

| Particle size | 10 – 150 μm | Affects flow, packing density, surface finish |

| Particle shape | Spherical, irregular | Impacts flowability, sintering |

| Apparent density | 2 – 5 g/cc | Influences compaction, shrinkage |

| Tap density | 4 – 8 g/cc | Indicates packing efficiency |

| Flow rate | 5 – 30 s/50g | Measure of flowability, affects mold filling |

| Oxygen content | 100 – 1000 ppm | Causes porosity and brittleness |

| Carbon content | <1000 ppm | Affects mechanical properties |

Controlling particle characteristics like size distribution, morphology, density, and chemistry is critical to achieve repeatable performance. Flowability determines processability. Lower oxygen and carbon boost mechanical properties.

Characteristics of Metal Alloy Powders

In addition to composition and powder properties, certain physical and microstructural characteristics determine the quality and capabilities of metal alloy powders:

Characteristics of Metal Alloy Powders

| Characteristic | Description | Significance |

|---|---|---|

| Microstructure | FCC, BCC, HCP phases | Impacts strength, ductility, toughness |

| Defects | Porosity, inclusions | Affect mechanical properties |

| Hardness | Range depending on alloy | Resistance to deformation |

| Residual stresses | From rapid solidification | Can cause distortion |

| Surface oxide | Thin oxide layer | Affects sintering, corrosion resistance |

| Morphology | Spherical, angular, irregular | Impacts density, flowability |

The unique solidification conditions during gas atomization result in fine, homogeneous microstructures. A spherical powder shape improves packing density. Careful control over defects and surface quality ensures reliable performance.

Specifications of Metal Alloy Powders

Metal alloy powders must meet certain specifications for composition limits, particle size distribution, apparent density, flow rate, and impurity levels based on applicable standards.

Metal Alloy Powder Specifications

| Parameter | Typical Specification | Standard |

|---|---|---|

| Particle size | -100/+325 mesh | ASTM B214 |

| Apparent density | ≥ 2.5 g/cc | ASTM B212 |

| Oxygen content | ≤ 2000 ppm | AMS 4992 |

| Nitrogen content | ≤ 150 ppm | AMS 4992 |

| Carbon content | ≤ 750 ppm | AMS 4992 |

| Tap density | ≥ 4.5 g/cc | MPIF 04 |

| Flow rate | ≤ 25 s/50g | ASTM B213 |

Specifications for composition, particle size distribution, flow rate, density, and impurity levels ensure the powder meets quality requirements for intended applications.

Size Range of Metal Alloy Powders

Metal alloy powders are classified into different size ranges based on the particle or grain size:

Metal Alloy Powder Size Range

| Size Range | Particle Size |

|---|---|

| Ultrafine | <10 μm |

| Fine | 10-25 μm |

| Medium | 25-45 μm |

| Coarse | 45-150 μm |

Ultrafine and nanopowders exhibit increased strength due to the Hall-Petch effect but can be challenging to handle. Fine and medium sizes offer a good balance of properties. Coarse powders have higher flowability.

The size range is selected based on final part requirements and manufacturing process constraints. Smaller sizes provide higher resolution but coarser powders fill dies faster.

Grades of Metal Alloy Powders

Various grades of metal alloy powders are available based on composition, particle size distribution, and production method:

Grades of Metal Alloy Powders

| Grade | Description | Applications |

|---|---|---|

| Standard | Common alloys, cost-effective | General use |

| High purity | Low oxygen, nitrogen | Aviation, medical |

| Vacuum grade | Degassed | Reduced porosity |

| Gas atomized | Spherical shape | Additive manufacturing |

| Water atomized | Irregular shape | Traditional press and sinter |

Standard grades offer a balance of properties and cost. High purity grades minimize impurities for critical applications. Vacuum grades are degassed to prevent porosity. Gas atomized powders have superior morphology. Water atomized grades are less expensive.

Global Standards for Metal Alloy Powders

Key international standards for metal alloy powder composition, testing methods, and specifications:

Global Standards for Metal Alloy Powders

| Standard | Description |

|---|---|

| ASTM | American standards for powder testing procedures |

| ISO | International standards for powder metallurgy |

| DIN | German standards body |

| JIS | Japanese standards |

| MPIF | Metal Powder Industries Federation standards |

These standards allow comparison between various metal alloy powder producers and ensure the powders meet the stringent requirements of different industries worldwide.

Applications and Uses of Metal Alloy Powders

Metal alloy powders enable production of high-performance parts using advanced manufacturing techniques across industries:

Applications of Metal Alloy Powders

| Industry | Application | Alloys used |

|---|---|---|

| Aerospace | Turbine blades, airfoils | Superalloys, titanium |

| Automotive | Connecting rods, gears | Tool steels, stainless steels |

| Medical | Implants, instruments | Cobalt chrome, stainless steel, titanium |

| Electronics | Contacts, connectors | Copper, silver |

| Industrial | Cutting tools, dies | Tool steels, tungsten carbide |

| Oil and gas | Valves, wellhead components | Stainless steels, Inconel |

Advanced nickel and titanium alloys produce strong, temperature resistant aerospace components. Automotive powertrain parts leverage high-performance steels. Biocompatible cobalt chrome and titanium are popular in medical devices. Metal alloy powders enable small, complex electronics parts. Industrial tooling benefits from hardened tool steels and carbides. Corrosion resistant alloys suit oil and gas hardware.

Suppliers of Metal Alloy Powders

Some of the major global suppliers of various metal alloy powder types include:

Key Suppliers of Metal Alloy Powders

| Company | Key Products |

|---|---|

| Sandvik | Stainless steels, tool steels, nickel alloys |

| Praxair | Titanium, nickel, and cobalt alloys |

| Carpenter | Tool steels, stainless steels, alloys |

| Höganäs | Tool steels, stainless steels |

| GKN | Aluminum and titanium alloys |

| LPW Technology | Nickel alloys, tool steels |

These companies manufacture powders using various atomization techniques and specialized processes to control powder characteristics like particle size, shape, density, and oxide levels.

Cost Analysis of Metal Alloy Powders

Metal alloy powder prices depend on composition, purity levels, particle size distribution, and order quantity:

Metal Alloy Powder Pricing

| Alloy | Price Range |

|---|---|

| Stainless steel | $3-12 per lb |

| Tool steel | $6-20 per lb |

| Titanium alloys | $50-200 per lb |

| Nickel alloys | $15-80 per lb |

| Cobalt alloys | $50-250 per lb |

Stainless steels and tool steels are economical. Titanium and nickel superalloys are costlier due to raw material prices and processing difficulties. Limited availability increases cobalt alloy costs. Reduced oxygen grades command premium pricing.

High-volume orders receive discounted bulk rates. Small quantities and custom alloys cost more. Overall powder metallurgy provides significant cost savings over bulk alloys by reducing waste.

Pros and Cons of Metal Alloy Powders

Advantages of Metal Alloy Powders:

- Greater alloy flexibility compared to wrought alloys

- Ability to manufacture complex, net-shape parts

- Good dimensional tolerances and surface finish

- Minimized material waste due to high buy-to-fly ratio

- Lower energy consumption than bulk metal processing

- Shorter manufacturing time relative to machining

Limitations of Metal Alloy Powders:

- Higher cost than wrought alloys in some cases

- Limitations on maximum part size

- Requirement of controlled atmospheres during processing

- Lower ductility and toughness versus bulk alloys

- Higher residual porosity compared to cast and wrought alloys

- Challenging to handle ultrafine and nanopowders

Despite some limitations, metal alloy powders offer distinct advantages over bulk alloys for manufacturing of customized, high-performance components spanning diverse industries.

Future Outlook for Metal Alloy Powders

The future looks bright for wider adoption of metal alloy powders:

- Developments in additive manufacturing using exotic alloys will expand applications

- Higher purity grades will improve mechanical properties

- Tighter particle size distributions will enable finer features

- Lower cost manufacturing techniques like metal binder jetting will improve affordability

- Increased demand from electronics and industrial sectors beyond aerospace

- High strength aluminum and titanium alloys for lightweighting

- New alloy compositions for specialized electrical, magnetic, or thermal properties

- Consolidation among major powder suppliers will continue

With expanded capabilities, lower costs, and new advanced alloys, metal alloy powders are poised for robust long-term growth across multiple industries.

Metal Alloy Powders – Frequently Asked Questions

Q: What are the main advantages of using metal alloy powders?

A: Metal alloy powders provide benefits like flexibility in compositions, ability to manufacture complex net shape parts, good dimensional tolerances and surface finish, high buy-to-fly ratio resulting in less waste, lower energy use, and shortened manufacturing time relative to machining.

Q: What industries use metal alloy powders the most?

A: The aerospace, medical, automotive, oil and gas, and industrial sectors are major consumers of metal alloy powders for manufacturing critical components. The electronics industry also relies on metal powders for contacts, connectors, and micro-components.

Q: How are metal alloy powders made?

A: Metal alloy powders are produced by atomization of molten alloys using gas or water. The melt stream is broken into fine droplets that solidify into powder particles with controlled sizes and morphology.

Q: What is the typical size range of metal alloy powders?

A: Common size ranges are 10-25 microns for fine powders, 25-45 microns for medium powders, and 45-150 microns for coarse powders. Ultrafine powders under 10 microns and nanopowders below 1 micron are also produced in certain cases.

Q: What is the most widely used metal alloy powder?

A: Stainless steel is the most common alloy system used in powder metallurgy due to its good corrosion resistance, adequate mechanical properties, and relatively low cost. 316L and 17-4PH are popular grades for many applications.

Q: Can metal alloys that are difficult to machine be made into powders?

A: Yes, one major advantage of metal powders is the ability to produce complex shapes in alloys like superalloys, titanium alloys, and tool steels that are typically very challenging to machine.

Q: What methods are used to make parts from metal alloy powders?

A: The main manufacturing techniques are powder compaction into a die followed by sintering, metal injection molding, and additive manufacturing methods like binder jetting, laser powder bed fusion, and electron beam melting.

Q: How are the properties of metal alloy powders controlled and ensured?

A: Properties are controlled through strict monitoring of composition, particle size distribution, powder morphology, density, flow characteristics, microstructure, and contaminant levels based on applicable standards for each alloy system and end use requirements.

Q: Can metal alloy powders be recycled?

A: Yes, unused powder can be recovered and reused in many cases. Some powders containing hazardous elements require specialized recycling to recover the metals safely.