Molybdenum disulfide added to the grease can improve the grease’s lubricating capacity,

load-bearing capacity, and can reduce the wear and friction coefficient,

in the grease film undergoes a brief impact compound or high heat, acting as a replenishment.

The addition of molybdenum disulfide to grease increases the PB (maximum non-jamming load),

PD (maximum sintering load) values and reduces the diameter of the wear spot.

| Molybdenum disulfide Sources | Molybdenum disulfide added particle size and proportion | Max. clamping load PB(N) | Sintering load PD(N) | Abrasive Diameter (392N)mm |

| Other Brand | No additive | 441,3 | 980.7 | 0.77 |

| 1.5μm,1% | 411.9 | 1569.1 | 0.56 | |

| 1.5μm,2% | 509.9 | 1961.3 | 0.49 | |

| 1.5μm,3% | 509.9 | 2451.7 | 0.51 | |

| 3-5μm,2% | 559.0 | 1961.3 | 0.61 | |

| 12-16μm,2% | 657.0 | 1961.3 | 0.70 | |

| MODTC | 2% | 755.1 | 2451.1 | 0.41 |

| TRUER | 3.788μm,2% | 559.0 | 2451.7 | 0.64 |

| 17.45μm, 2% | 706.1 | 2451.7 | 0.69 |

| Recommended Specifications for Grease Industry(Purity>98.0%) | |||

| Grades | z-1 | Z-2 | |

| Parameter(maximum value) | |||

| Molybdenum trichloride(%) | 0.50 | 0.50 | |

| acid-insoluble substance(%) | 0.25 | 0.25 | |

| Iron(%) | 0.30 | 0.20 | |

| Water(%) | 0.20 | 0.30 | |

| Oil(%) | 0.40 | 0.40 | |

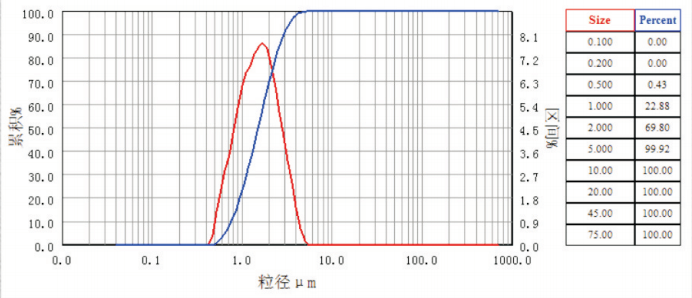

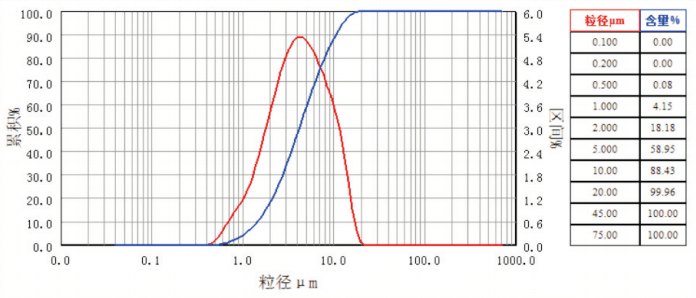

| Particle size | D50μm | 1.50 | 6.00 |

| D90μm | 5.00 | 20.00 |

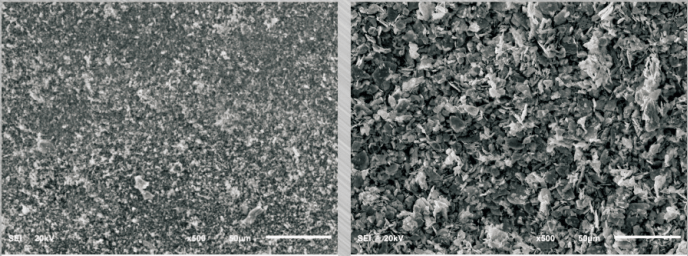

Z-1 500X electroencephalogram z-2 500X electroencephalogram

z-1 granularity map

Z-2 granularity map

.jpg)