Table of Contents

ToggleUnderstanding Gas Atomizer Equipment

Significance and Process

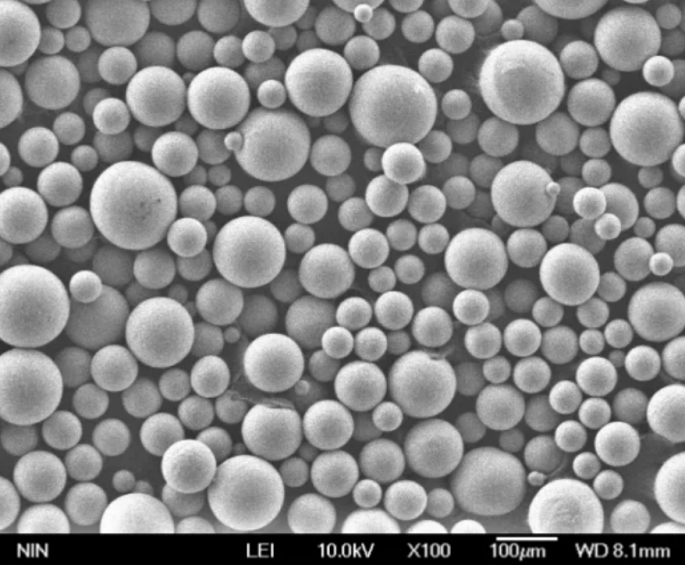

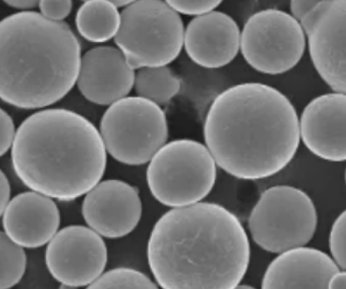

Gas atomizer equipment is essential for producing high-quality, gas-atomized powders used across various industries. The process involves selecting raw materials, melting, atomizing with a high-velocity gas stream, and collecting the resulting spherical particles after rapid cooling1.

Advantages and Applications

These powders boast high purity, consistent size distribution, enhanced flowability, and improved sphericity. Applications include additive manufacturing, metal injection molding, thermal spray coatings, powder metallurgy, brazing, and soldering.

Cost and Types

Costs range from $10,000 for small-scale equipment to over $1.5 million for industrial systems. Types differ by atomization medium (gas or water) and nozzle design, influencing powder size and maintenance needs.

Critical Functions

- Conversion to Powder: Essential for additive manufacturing.

- Particle Size Control: Allows for specific particle sizes suited to different applications.

- Alloy Creation: Enables the production of novel alloys.

- Optimized Flow Rates: Affects particle size and shape.

- Rapid Solidification: Leads to unique microstructures and material properties.

Selection Considerations

Selecting the right equipment requires understanding specifications, ensuring proper installation and maintenance, and choosing reliable suppliers.

Cost of Gas Atomizer Equipment

The cost of gas atomizer equipment varies significantly depending on several factors including capacity, technology, brand, and additional specifications. Here’s a general outline:

| Equipment Scale | Cost Range |

|---|---|

| Small-scale | Starting from $10,000 |

| Large-scale | Up to and beyond $1,500,000 |

For small-scale, lab-based setups, prices begin at around $10,000, while large-scale, industrial systems can cost upwards of $1.5 million. The total cost of ownership also includes considerations for financing, maintenance, operational costs, and potential resale value1.

Types of Gas Atomizer Equipment

Gas atomizer equipment comes in various types, primarily distinguished by the atomization medium and nozzle design:

| Atomization Medium | Nozzle Design | Description |

|---|---|---|

| Gas | Simplex Nozzles | Economical, produces larger powder sizes. |

| Gas | Multiple Nozzles | Enhances metal stream disintegration for finer powders. |

| Gas | Close-Coupled | Creates very fine powders, suitable for reactive alloys. |

| Gas | Rotating Electrodes | Employs centrifugal forces for uniform powder size, complex and requires more maintenance“oaicite:{“number”:1,”metadata”:{“type”:”webpage”,”title”:”understanding gas atomizer equipment |

Functions of Gas Atomizer Equipment

Gas atomizer equipment serves several pivotal functions in the manufacturing process:

| Function | Description |

|---|---|

| Conversion to Powder | Transforms molten metal into fine droplets, solidifying into powders essential for manufacturing. |

| Particle Size Control | Enables precise control of particle size for various application needs. |

| Alloy Creation | Facilitates the production of new metal alloys by atomizing mixed metals. |

| Flow Rate Optimization | Controls the molten metal flow rate, affecting particle size and shape. |

| Rapid Solidification | Achieves quick solidification, leading to unique material properties and microstructures“oaicite:{“number”:1,”metadata”:{“type”:”webpage”,”title”:”understanding gas atomizer equipment |

Applications of Gas Atomizer Equipment

Gas atomizer equipment is used in various applications, each leveraging the unique properties of gas-atomized powders:

| Application | Description |

|---|---|

| Additive Manufacturing (3D Printing) | Critical for producing complex components via processes like SLM and EBM. |

| Metal Injection Molding (MIM) | Powders mixed with a binder to create detailed parts with excellent mechanical properties. |

| Thermal Spray Coatings | Enhances wear resistance, corrosion protection, and thermal insulation of substrates. |

| Powder Metallurgy | Used in compaction and sintering processes, prevalent in automotive, aerospace, and medical industries. |

| Brazing and Soldering | Provides strong, reliable joints in metal assemblies with tailored powders“oaicite:{“number”:1,”metadata”:{“type”:”webpage”,”title”:”understanding gas atomizer equipment |

Benefits of Gas Atomizer Equipment

The utilization of gas atomizer equipment offers numerous benefits:

| Benefit | Description |

|---|---|

| High Purity | Produces powders with minimal contamination, essential for high-quality manufacturing outcomes. |

| Consistent Quality | Ensures superior particle size distribution for homogeneous end products. |

| Enhanced Flowability | Aids in processing by improving powder flow, reducing wastage, and enhancing efficiency. |

| Improved Sphericity | Contributes to better packing density and reduced porosity in final products. |

| Customizability | Allows precise control over powder properties to meet specific industry needs“oaicite:{“number”:1,”metadata”:{“type”:”webpage”,”title”:”understanding gas atomizer equipment |

Choosing the Right Gas Atomizer Equipment

Selecting suitable gas atomizer equipment involves several critical considerations:

| Consideration | Description |

|---|---|

| Equipment Specifications | Match the equipment’s capabilities with your production needs, like furnace and nozzle types. |

| Installation and Maintenance | Ensure proper setup and regular maintenance to prolong lifespan and guarantee consistent quality. |

| Supplier Selection | Look for suppliers with a strong track record in quality, customization ability, and safety standards“oaicite:{“number”:1,”metadata”:{“type”:”webpage”,”title”:”understanding gas atomizer equipment |

Top Manufacturers of Gas Atomizer Equipment

The manufacturing landscape for gas atomizer equipment features a number of key players, each bringing their own technological advancements and specialties to the market:

| Manufacturer | Specialization |

|---|---|

| Retech | Offers metal atomization systems that utilize melting technologies combined with gas atomization and other methods |

| Topcast | Produces a range of gas atomizers, specializes in closed-coupled nozzle configuration for a variety of metal powders2. |

| Blue Power | Known for small to medium batch production, expanding portfolio to include ultrasonic and water atomization solutions |

| SMS group | Provides large-scale powder manufacturing with innovative processes and systems like the anti-satellite and hot gas systems. |

Purchasing Gas Atomizer Equipment

When looking to purchase gas atomizer equipment, consider the following avenues:

| Purchase Method | Description |

|---|---|

| Manufacturer Direct | Contact manufacturers like Retech, Topcast, Blue Power, or SMS group directly for quotations. |

| Distributors & Agents | Use official distributors who can offer localized services and support. |

| Industry Tradeshows | Attend events to see the equipment firsthand and discuss directly with suppliers. |

| Online Marketplaces | Check platforms that list various manufacturers and compare equipment specs and prices. |

| Used Equipment Dealers | For budget options, consider certified pre-owned equipment from reputable dealers. |

The product advantages of Chinese gas atomizer equipment are emphasized through their ability to produce gas atomized powders that cater to a wide range of industry needs. The main benefits include:

- High Purity: The atomization process minimizes contamination, resulting in high purity levels.

- Superior Particle Size Distribution: Ensures consistency and homogeneity in end products.

- Enhanced Flowability: Aids in efficient processing.

- Improved Sphericity: Contributes to better packing density and reduced porosity in products.

- Customizability: Allows precise control over powder properties to meet specific application requirements1.

Best Supplier for Chinese Gas Atomizer Equipment

Zhuzhou Hanhe Industrial Equipment Co., Ltd. is recognized as a leading supplier in China for gas atomization equipment. They offer:

- Top-Quality Production: Specialized in creating fine and uniform metal particles, crucial for metallurgy and additive manufacturing.

- Cutting-Edge Technology: Features advanced nozzle designs and control systems for precision.

- Robust Manufacturing: Ensures durable equipment suited for both laboratory and industrial scales.

- Customer Satisfaction: Committed to exceeding expectations with their products1.