Tabla de contenidos

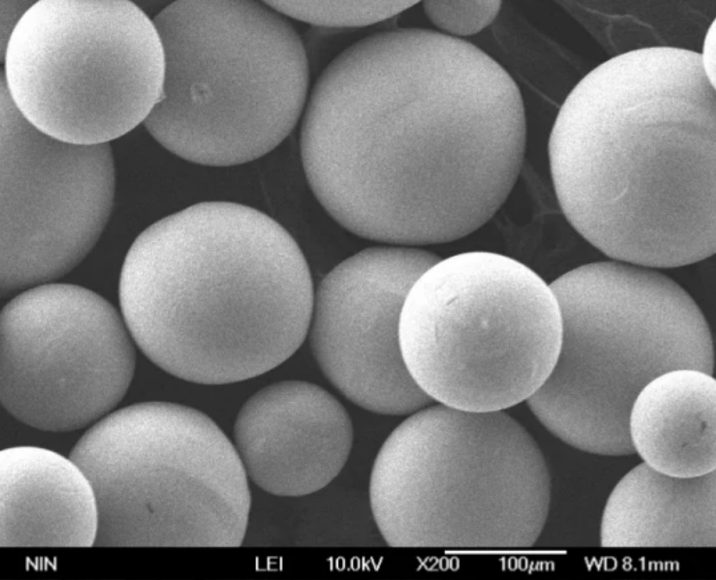

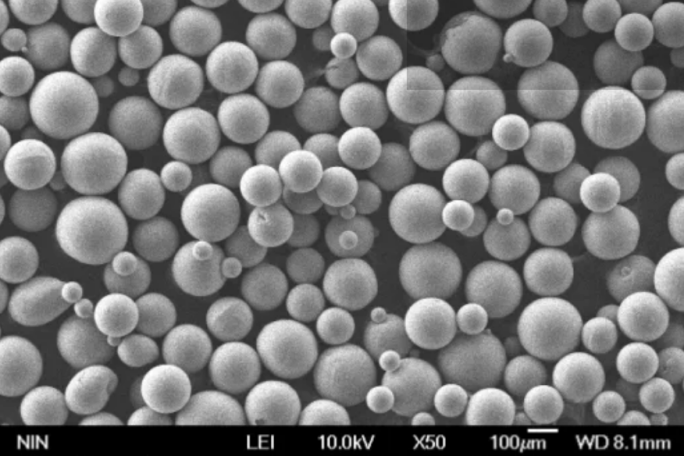

ToggleSilicon powder is a fine granular form of silicon that has widespread use across many industries due to its unique properties and capabilities. This powdered crystalline silicon offers advantages over bulk silicon including ease of handling, processing, and integration into finished products.

Overview of Silicon Powder

Silicon powder goes by many names – crystalline silicon powder, polysilicon powder, semiconductor-grade silicon powder, solar-grade silicon powder, metallurgical-grade silicon powder, and more. At a broad level, silicon powders can be categorized by purity levels, material properties, production methods, particle size ranges, and applications.

The silicon content of powders can vary from 98% pure semiconductor-grade suitable for electronics, to 95% solar-grade for photovoltaics, to 90% metallurgical-grade for alloying elements. The powder particle size also differs widely from coarse micrometer-scale particles to ultrafine nanometer-scale particles.

Key properties and composition details of some common types of silicon powders are shown below:

| Type | Purity | Particle Size | Production Method |

|---|---|---|---|

| Semiconductor-grade | 99.999999% | 1-100 μm | Chemical vapor deposition |

| Solar-grade | 99.9999% | 1-100 μm | Metallurgical process |

| Metallurgical-grade | 98-99% | 1-500 μm | Metallurgical process |

| Nanoscale | 99%+ | 1-100 nm | Gas phase synthesis |

The wide range of silicon powder varieties allows it to serve many distinct applications across electronics, solar panels, metals, ceramics, polymers, and more.

Properties of Silicon Powder

The unique properties of silicon make its powdered forms useful for specialized applications in comparison to other metal powders.

Some noteworthy properties include:

- Semiconducting – Pure silicon powder has semiconducting properties crucial for microelectronics

- Photovoltaic – Converts sunlight due to semiconducting properties

- Reactive – Silicon readily forms compounds with oxygen, halogens, metals etc.

- Hardness – Silicon has a Mohs hardness score of 6.5 to 7, harder than most metals

- Oxidation resistance – Forms protective silicon dioxide layer on surface upon oxidation

- Thermal resistance – High melting point of 1414°C makes silicon resistant to heat

- Non-toxic – Chemically inert and safe for many medical applications

These properties lend silicon powder towards roles from improving mechanical strength in alloys, providing electrically conductive pathways in batteries, absorbing UV rays in cosmetics, and more.

Production Methods for Silicon Powder

Silicon does not occur in nature in its pure elemental form due to its reactivity. It naturally occurs as silicon dioxide or silicates compounds. Thus commercial silicon powder production involves the processing of natural minerals and chemical feedstocks.

There are two broad categories of silicon powder production methods:

- Metallurgical Processes – Involves the high temperature chemical reduction of silicon dioxide using carbon or hydrogen gas. Yields lower purity silicon suitable for metallurgical and solar applications.

- Chemical Vapor Deposition – Decomposes reactive silicon hydride/halide gas molecules into ultrafine silicon powder. Yields ultrahigh purity powder for electronics.

Some more details on these methods are outlined below:

| Method | Process | Typical Purity | Scalability |

|---|---|---|---|

| Metallurgical | Silica reduction with carbon/hydrogen at 1800-2000°C | 95-99% | High tonnage output |

| Chemical Vapor Deposition (CVD) | Gas molecules decomposed at ~1100°C on substrates | 99.9999999% | Lower output for electronics |

| Gas Phase Synthesis | Reactions of silane/chlorosilane gases at 300-1500°C | Up to 99.9999% | Moderate tonnage output |

The optimal production technique depends on the desired material qualities and end application specifications.

Applications of Silicon Powder

The versatile powdered forms of silicon serve a diverse array of applications across industries like electronics, photovoltaics, chemicals, metallurgy, polymers, and more.

Some of the popular applications of silicon powders are shown below:

| Industry | Applications |

|---|---|

| Electronics | Semiconductors, integrated circuits, transistors |

| Solar Photovoltaics | Solar panels, cells, ingots |

| Metallurgy | Alloying element, deoxidizer |

| Ceramics | Silicon carbide, silicon nitride |

| Polymers | Fillers for resins, plastics, rubbers |

| Chemicals | Silicones, silanes, fumed silica |

The applications make use silicon powders with varying composition, particle size distribution, specific surface area, tap density/bulk density, and more parameters.

Silicon Powder Specifications

Silicon powders meant for electronics usage adhere to very stringent purity and uniformity specifications suitable for microfabrication processes. Typical parameters are shown below:

| Parameter | Typical Specification |

|---|---|

| Si content | >99.9999999% |

| Metal impurities (each) | <1 pptw |

| Boron, Phosphorus | <0.05 pptw |

| Oxygen | < 5 ppbw |

| Carbon | < 1 ppbw |

| Particle size distribution | Average ~50 μm |

| Tap density | > 1.1 g/cc |

Specifications for metallurgical and solar silicon powder grades are more relaxed since ultrahigh purity is not required.

Silicon Powder Suppliers

With silicon being one of the most important industrial materials globally, there are a large number of established corporations and specialty manufacturers that produce silicon powders.

Some of the major global suppliers are:

- REC Silicon – Leading supplier for semiconductor, solar, electronics industries

- Ferroglobe – Metallurgical and solar silicon powders

- Elkem – Major metallurgical silicon alloys producer

- Dow Chemicals – Ultrafine amorphous silicon powders

- American Elements – Wide range of silicon purities/morphologies

Pricing depends strongly on market demand/supply dynamics and material purity grades. Some typical price ranges are:

| Grade | Pricing |

|---|---|

| Semiconductor-grade Si powder | $80-150 per kg |

| Solar-grade Si powder | $15-30 per kg |

| Metallurgical-grade Si powder | $5-15 per kg |

Pros vs Cons of Silicon Powder

Some advantages and disadvantages of using silicon in powdered form rather than as a bulk material:

| Pros | Cons | |

|---|---|---|

| Ease of use | Flowable, can be suspended, compressed | Prone to aggregation over time |

| Processing | Easily integrated into fluids or melts | Oxidation/contamination risks |

| Kinetics | Rapid reactions due to high surface area | Side reactions can also occur |

| Purity | Ultrahigh purities achievable | Lower overall purity than bulk Si |

| Cost | Small quantities are affordable | Scale-up to bulk quantities expensive |

The choice depends on weighing the priorities for the particular application.

FAQ

| Questions | Answers |

|---|---|

| What are the different grades of silicon powder? | Major grades are semiconductor-grade (9N+ purity), solar-grade (6N+), metallurgical grade (5N), and nanoscale powder. |

| What particle size is best for silicon powders? | 1-100 μm size is common. Smaller nano powder below 100 nm offers unique properties. |

| What characteristics of silicon powder make it useful compared to bulk silicon? | High specific surface area, flowability, integration into composites/alloys, tuning electrical/optical properties, controlled powder morphology. |

| What are the typical impurity limits for semiconductor-grade silicon powder? | Oxygen below 5 ppbw, carbon below 1 ppbw, metallic impurities below 1 pptw, and dopant levels below 0.05 pptw. |

| What precautions are necessary when handling silicon powder? | Avoid contact with moisture and oxygen. Store in inert containers. Use dust masks as nanoparticles can be respiratory hazards. |

Conclusion

In summary, silicon powder offers distinct advantages in ease of processing, versatility of applications, tunability of material properties, and ultrahigh purities. With innovative production methods, changing industry demands, and expanded usage across emerging technologies, silicon powder will continue to be a critical and growing material in the future.