Table of Contents

Toggle3d printing inconel 625 is a nickel-chromium-molybdenum alloy with excellent high temperature strength and corrosion resistance. This makes it well-suited for 3D printing complex geometries for demanding applications. This guide provides an overview of composition, properties, parameters, and uses of 3D printed Inconel 625.

Introduction to 3d printing inconel 625

Inconel 625 is a high performance superalloy frequently used for additive manufacturing across aerospace, marine, nuclear, and chemical industries. Key properties include:

Table 1: Overview of 3D printed Inconel 625 material

| Properties | Details |

|---|---|

| Nickel Content | 58-63% |

| High Strength | Tensile strength 1,310 MPa |

| Temperature Resistance | Up to 1,400°F or 760°C |

| Corrosion Resistance | Highly resistant to heat, acids, alkaline |

| Crack Resistance | Excellent fatigue strength and toughness |

| Workability | Readily weldable for joining |

| Common Uses | Aerospace, marine, industrial applications |

3D printing enables fabricating complex Inconel 625 parts unattainable with traditional methods. Continuing reading for details on composition, characteristics, printing process parameters, applications and more.

Chemical Composition of 3d printing inconel 625

The Inconel 625 alloy chemistry includes nickel, chromium, molybdenum, niobium and iron:

Table 2: Inconel 625 alloy composition

| Element | Weight % |

|---|---|

| Nickel (Ni) | 58.0 – 63.0 % |

| Chromium (Cr) | 20.0 – 23.0 % |

| Molybdenum (Mo) | 8.0 – 10.0 % |

| Niobium (Nb) | 3.15 – 4.15 % |

| Iron (Fe) | Remainder |

| Carbon (C) | ≤ 0.10% |

| Manganese (Mn) | ≤ 0.50% |

| Silicon (Si) | ≤ 0.50% |

| Phosphorus (P) | ≤ 0.015% |

| Sulfur (S) | ≤ 0.015% |

| Aluminum (Al) | ≤ 0.40% |

| Titanium (Ti) | ≤ 0.40% |

| Cobalt (Co) | ≤ 1.0% |

This carefully optimized nickel-chromium matrix provides an exceptional combination of heat and corrosion resistance while retaining ductility, fatigue strength, and weldability.

Mechanical Properties of 3D Printed Inconel 625

The mechanical properties of Inconel 625 make it suitable for demanding applications:

Table 3: Inconel 625 mechanical properties

| Property | Value |

|---|---|

| Density | 8.44 g/cm3 |

| Melting Point | 2,300-2,460°F (1,260-1,350°C) |

| Tensile Strength | 125,000 – 240,000 psi |

| Yield Strength (annealed) | 110,000 psi min |

| Elongation | 30% minimum |

| Young’s Modulus | 29 x 10^6 psi |

| Poission’s Ratio | 0.29 |

| Fatigue Strength | 110 – 129 ksi |

| Fracture Toughness | 200 ksi√in |

| Hardness | ~35 HRC |

The combination of strength, cracking resistance, thermal properties, and corrosion resistance enable Inconel 625 to endure extreme environments.

Key Benefits of Inconel 625 for 3D Printing

3D printed Inconel 625 offers major advantages:

Table 4: Advantages of 3D printing Inconel 625 parts

| Benefits | Description |

|---|---|

| High strength-to-weight ratio | As strong as steel at a fraction of the weight, saving costs |

| Withstands extreme temperatures | Retains mechanical properties from cryogenic to 1,400°F |

| Corrosion resistance | Excellent chemical resistance to acids, alkaline solutions up to 1,400°F |

| Crack resistance | High fatigue strength resists fracture failure |

| Thermal stability | Low coefficient of thermal expansion avoids distortion |

| Food safe | Approved for food processing equipment with no leaching |

| Custom alloys | Can customize chemistry for application requirements |

| Complex geometries | Print intricate shapes unattainable with fabrication |

| Consolidated assemblies | Print complex assemblies without welding, reducing costs |

| Rapid iteration | Engineer, test, adapt parts through rapid prototypes |

These advantages expand design possibilities and enable lighter, stronger and longer-lasting components.

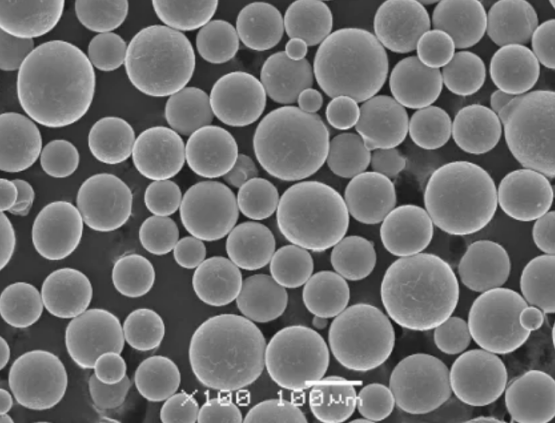

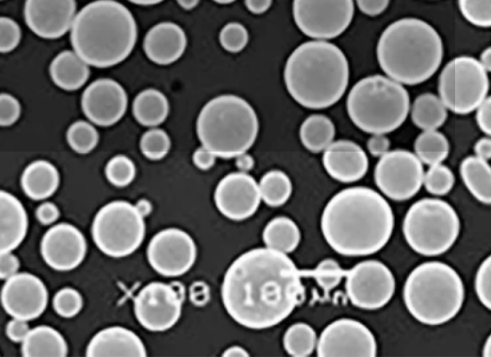

Recommended 3D Printing Parameters for Inconel 625

Here are typical process parameters when printing Inconel 625 parts on laser powder bed fusion and directed energy deposition systems:

Table 5: Inconel 625 standard 3D printing parameters

| Parameter | Typical value |

|---|---|

| Layer thickness | 20 – 100 microns |

| Laser power | Up to 500 W |

| Scan speed | 800 – 1200 mm/s |

| Beam diameter | 50 – 200 microns |

| Powder size | 15 – 45 microns |

| Print orientation | 45° angles |

| Support structures | Mandatory |

| Annealing | Optional 2,100 – 2,300°F for 2 hrs |

Settings must balance density against residual stresses. Following established methods like ASTM F3056 minimizes cracking and distortions. Let’s look at common applications next.

Applications of 3D Printed Inconel 625 Parts

Common uses of additively manufactured Inconel 625 across industries include:

Table 6: Inconel 625 3D printing applications

| Industry | Applications | Components |

|---|---|---|

| Aerospace | Structural brackets, engine components, hydraulic systems | Turbine blades, rocket nozzles, exhaust manifolds, fuel elements |

| Oil and gas | Downhole tools, valves, wellhead systems | Drill bits, wireline tools, Christmas trees |

| Automotive | Turbochargers, exhaust components | Manifold, supercharger rotor housing, turbo impellers |

| Chemical processing | Heat exchangers, reaction vessels, pipe fittings | Pipe spools and elbows, mixing blades, process equipment |

| Food and pharmaceutical | Mixers, dryers, heaters, conveyors | Bearings, shafts, fasteners, connectors |

| Marine | Propulsion components, desalination systems | Pumps, impellers, couplings, valves |

| Power generation | Heat exchangers, steam system components | Headers, superheater tubing, condenser tubes |

3D printing enables lighter, stronger and custom Inconel 625 parts consolidating complex assemblies across demanding applications, driving adoption in critical systems.

Material Options for 3D Printing Inconel 625

Popular Inconel 625 alloy options for additive manufacturing include:

Table 7: Common 3D printing Inconel 625 material formats

| Type | Description | Key Properties |

|---|---|---|

| Inconel 625 Standard | Most widely used grade for additive | Tensile strength 1050 MPa, rupture strength 760 MPa at 980°C |

| Inconel 625 Ultra | Higher density and ductility | 30% increased yield and tensile strength |

| Inconel 718 | Heat resistant aerospace grade | Excellent strength and hardness >540°C |

| Custom 625 alloys | Application-specific custom chemistry | Enhanced emissivity, conductivity, magnetism etc |

Specialized Inconel powders optimize particle shape, size and chemistry to boost 3D printing success.

Inconel 625 3D Printing Standards

Key standards for qualifying 3D printed Inconel 625 parts and powders:

Table 8: Inconel 625 alloy 3D printing standards

| Standard | Description |

|---|---|

| ASTM F3056 | Standard specification for additive manufacturing nickel alloy |

| ASTM B946 | Standard for detection of defects |

| AMS 2801 | Heat treatment of nickel alloys |

| AMS 5662 | Laser powder bed fusion process requirements |

| ISO/ASTM 52900 | General principles for design and manufacture |

Certifying printed Inconel components per these specifications ensures high quality and reliability for service.

Suppliers of Inconel 625 for 3D Printing

Leading suppliers of Inconel 625 metal powders include:

Table 9: Inconel 625 powder suppliers

| Supplier | Description | Pricing |

|---|---|---|

| LPW Technology | Wide alloy range, custom particle optimization | $$$ |

| Sandvik Osprey | Standard and custom nickel alloy powders | $$$ |

| Erasteel | Broad superalloy material portfolio | $$ |

| AMG Superalloys UK | Specialize in nickel alloys | $-$$ |

| Tekna | Advanced plasma spheroidization process | $$$ |

These premium alloy specialists fine-tune Inconel 625 particle size, shape, chemistry and defects to ensure printing success.

Pros vs Cons of 3D Printed Inconel 625

Table 10: Advantages and limitations of Inconel 625 3D printing

| Pros | Cons |

|---|---|

| Withstands 1800°F temperature swings | More costly than steel or aluminum |

| Five times more fracture resistant than steel | Requires heat treatment to relieve stresses |

| Half the density of steel | Susceptible to micro-cracking without optimization |

| Resists hot corrosion and pitting | Hard to print overhangs requiring supports |

| Bio-compatible for food and medical uses | Limited large-scale suppliers and printers |

| Print complex geometries consolidating assemblies | Post-processing can be challenging |

With sound process practices, the tremendous performance benefits of 3D printed Inconel 625 outweigh higher part costs.

FAQ

Q: What causes cracking when printing Inconel 625?

A: High cooling stresses from large thermal gradients lead to cracking. Proper support structures, optimized process settings, pre/post-heat treatment, and machining reliefs all help minimize cracking.

Q: Does 3D printed Inconel 625 require heat treatment?

A: Optional heat treatment relieves internal stresses, enhancing mechanical properties and crack resistance. Annealing at 1900-2100°F for 1-3 hours is typical based on section thickness.

Q: What surface finish can be expected on as-printed Inconel 625 parts?

A: Raw surface finish ranges from 250-500 microns Ra depending on print parameters. Additional machining, grinding, polishing or electropolishing can enhance surface finish requirements.

Q: Can you weld 3D printed Inconel 625?

A: Yes, Inconel 625 can be readily welded using GTAW, electron beam or laser welding methods for joining 3D printed assemblies or modifying components. Proper fixturing is critical to avoid distortions.