Table of Contents

Toggle1. Introduction

In recent years, 3D printing technology has revolutionized various industries, enabling the production of complex and customized objects with ease. One of the key aspects of 3D printing is the material used, and when it comes to metal 3D printing, 3d printing metal powder price plays a significant role. This article delves into the factors influencing 3d printing metal powder price, the cost structure, comparisons between different metal powders, strategies for reducing costs, and the future outlook for metal powder prices.

2. What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering materials based on a digital model. Unlike traditional manufacturing methods that involve subtractive processes, 3D printing builds objects layer by layer, allowing for intricate designs and customization. This technology has gained widespread adoption across industries such as aerospace, automotive, healthcare, and consumer goods.

3. Advancements in Metal 3D Printing

Metal 3D printing has emerged as a game-changer in the manufacturing sector. It enables the production of parts with complex geometries, lightweight structures, and improved mechanical properties. The ability to create intricate designs and functional prototypes directly from metal powders has opened up new possibilities for industries seeking efficient and cost-effective manufacturing solutions.

4. Metal Powder for 3D Printing

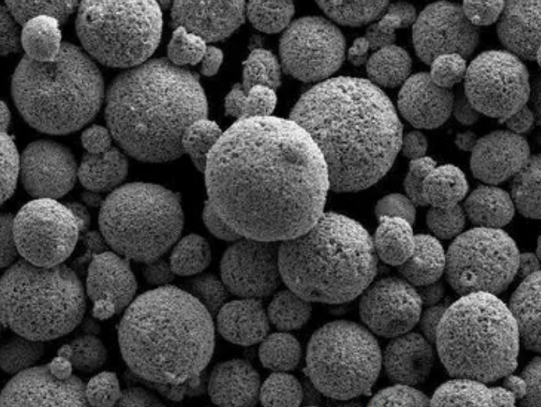

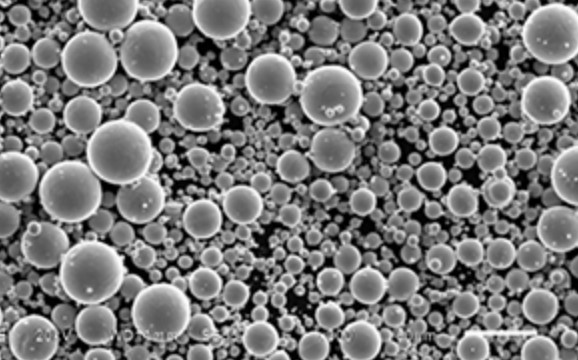

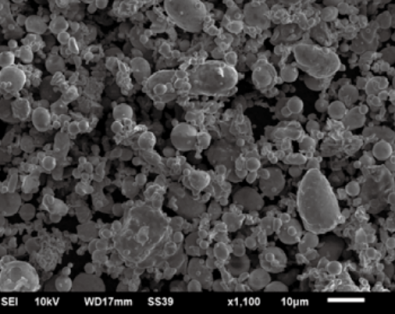

Metal powders are the primary materials used in metal 3D printing. These powders consist of fine particles of metals, alloys, or metal-based composites. The properties of the metal powders, such as composition, particle size, and shape, have a direct impact on the quality and characteristics of the printed parts.

5. Factors 3d printing metal powder price

3d printing metal powder price is influenced by various factors. Understanding these factors is crucial for both manufacturers and consumers to make informed decisions. The following are key factors that affect 3d printing metal powder price:

5.1 Powder Composition and Purity

Different metals and alloys have varying costs due to their availability, extraction processes, and demand. Rare or exotic metals tend to have higher prices compared to common ones. Additionally, the purity of the powder, often expressed as a percentage, affects 3d printing metal powder price. Higher purity powders usually command a premium due to the additional refining processes involved.

5.2 Powder Particle Size and Distribution

The particle size and distribution of metal powders impact the printing process and the final quality of the printed parts. Powders with a narrow particle size distribution and smaller particle sizes generally result in better surface finish, higher density, and improved mechanical properties. However, these powders often come at a higher cost due to the increased complexity of the production process.

5.3 Powder Production Method

The method used to produce metal powders also affects 3d printing metal powder price. Techniques such as gas atomization, water atomization, and plasma atomization have different cost implications. Each method has its advantages and limitations, and the choice of production method depends on the desired properties of the printed parts and the cost constraints.

5.4 Powder Supply and Demand

The dynamics of supply and demand in the metal powder market directly impact 3d printing metal powder price. When the demand for specific metal powders exceeds the available supply, prices tend to rise. Conversely, if the supply outpaces demand, prices may decrease. Additionally, geopolitical factors, trade policies, and market trends can influence the overall supply and demand balance.

5.5 Market Trends and Economic Factors

Market trends and economic conditions also play a significant role in 3d printing metal powder price. Fluctuations in commodity prices, currency exchange rates, and overall economic stability can impact the cost of metal powders. For example, if there is a shortage of raw materials or geopolitical tensions, prices may increase. Conversely, during periods of economic downturn or reduced demand, prices may decrease.

6. Understanding the Cost Structure

To fully comprehend 3d printing metal powder price, it’s essential to understand the cost structure involved. The cost of metal powders includes various components such as raw material costs, processing costs, quality control measures, packaging, and transportation expenses. Manufacturers also factor in research and development costs, equipment maintenance, and overheads when determining the final price.

7. Comparing Metal Powder Prices

Different metals and alloys have distinct price points in the metal powder market. Let’s compare the prices of some commonly used metal powders in 3D printing:

7.1 Titanium Powder

Titanium is a lightweight and high-strength metal widely used in aerospace and medical applications. The price of titanium powder can vary based on factors such as particle size, purity, and market demand. Typically, titanium powder is more expensive compared to other metal powders due to its scarcity and extraction complexities.

7.2 Stainless Steel Powder

Stainless steel is a popular choice for 3D printing due to its strength, corrosion resistance, and versatility. The price of stainless steel powder depends on the specific alloy, particle size distribution, and purity. Generally, stainless steel powder is more affordable compared to titanium powder.

7.3 Aluminum Powder

Aluminum is known for its low density, excellent thermal conductivity, and corrosion resistance. The cost of aluminum powder is relatively lower compared to titanium and stainless steel. However, factors such as alloy composition, particle size, and supply-demand dynamics can influence the 3d printing metal powder price.

7.4 Cobalt Chrome Powder

Cobalt chrome alloys are widely used in the medical and dental industries due to their biocompatibility and high strength. The price of cobalt chrome powder is generally higher compared to stainless steel and aluminum powders. Factors such as powder quality, purity, and market demand contribute to the price differential.

7.5 Nickel Alloy Powder

Nickel alloys offer excellent high-temperature performance and corrosion resistance, making them suitable for aerospace and energy applications. 3d printing metal powder price can vary depending on the specific composition, powder quality, and market factors. Generally, nickel alloy powders are priced higher than stainless steel and aluminum powders.

8. Strategies for Reducing Metal Powder Costs

Manufacturers and consumers alike can employ various strategies to mitigate metal powder costs. Here are some effective approaches to reducing metal powder expenses:

8.1 Material Optimization

Optimizing the material usage during the 3D printing process can help reduce powder consumption. Designing parts with less material waste and considering lattice structures or hollow geometries can lead to significant cost savings. Material simulation and optimization tools can assist in achieving optimal designs.

8.2 Process Optimization

Fine-tuning the printing process parameters can contribute to cost reduction. By optimizing parameters such as layer thickness, print speed, and energy settings, manufacturers can achieve a balance between quality and powder consumption. Process monitoring and control systems can help identify areas for improvement and optimize the overall printing process.

8.3 Supply Chain Management

Efficient supply chain management is essential for controlling metal powder costs. Collaborating closely with powder suppliers, negotiating favorable contracts, and ensuring timely delivery can help streamline operations and minimize costs. Building strong relationships with reliable suppliers and exploring alternative sourcing options can also lead to cost savings.

9. The Future of Metal Powder Prices

As the field of metal 3D printing continues to evolve, it is expected that metal powder prices will undergo further changes. Advancements in powder production techniques, increased competition, and economies of scale may contribute to price reductions over time. Additionally, advancements in recycling and reuse of metal powders can help drive down costs and promote sustainability in the industry.

10. Conclusion

3d printing metal powder price is a critical factor to consider when utilizing 3D printing technology for metal parts. Understanding the various factors that influence metal powder prices, including composition, particle size, production methods, supply and demand dynamics, and market trends, can help manufacturers and consumers make informed decisions. By implementing strategies for cost reduction and staying abreast of technological advancements, stakeholders can navigate the metal powder market effectively and optimize their 3D printing operations.

FAQs

Q1: Are all 3d printing metal powder price equally?

No, metal powders vary in price depending on factors such as composition, purity, production method, and market demand.

Q2: What are the cost-saving benefits of material optimization?

Material optimization in 3D printing can lead to reduced powder consumption, lower material waste, and cost-efficient designs.

Q3: How can process optimization contribute to cost reduction?

Process optimization helps achieve a balance between quality and powder consumption by fine-tuning printing parameters and improving overall efficiency.

Q4: Can supply chain management impact metal powder costs?

Efficient supply chain management, including supplier collaboration and alternative sourcing options, can help minimize costs and ensure timely delivery of metal powders.

Q5: What does the future hold for 3d printing metal powder price?

Advancements in technology, increased competition, and recycling initiatives are expected to influence metal powder prices, potentially leading to cost reductions and enhanced sustainability in the industry.