MoS2

Products Features

Molybdenum disulfide is an important solid lubricant that is particularly suitable for high temperature and high-pressure applications. It is also anti-magnetic and can be used as a linear photoconductor and as a semiconductor displaying P- or N-type conductive properties, with rectification and energy transfer. Molybdenum disulfide is also used as a catalyst for the dehydrogenation of complex hydrocarbons.

It is also known as the “King of Advanced Solid Lubricants”. Molybdenum disulfide is a solid powder made from natural molybdenum concentrate powder that has been chemically purified and its molecular structure changed.

The product is black with a slightly silvery gray color, metallic luster, smooth to the touch, insoluble in water.

The product has the advantages of good dispersion, no bond, can be added to all kinds of grease, forming a colloidal state never bond, can increase the lubricity of grease and extreme pressure. Also applicable to high temperature, high pressure, high speed, and high load mechanical working conditions, to extend the life of the equipment.

Molybdenum disulfide is used for friction materials, the main function is to reduce friction at low temperatures, high-temperature friction, the amount of burning loss is small, easy to volatilize in the friction materials.

Friction reduction: molybdenum disulfide particle size reached 325-2500 mesh by supersonic airflow crushing processing, micro-particle hardness 1-1.5, friction coefficient 0.05-0.1, so it can be used in friction materials can play a role in reducing friction.

Friction: Molybdenum disulfide is non-conductive and exists as a copolymer of molybdenum disulfide, molybdenum trisulfide, and molybdenum trioxide. When the temperature of a friction material rises sharply due to friction, the molybdenum trioxide particles in the copolymer expand as they warm, increasing friction.

Anti-oxidation: Molybdenum disulfide is obtained through a comprehensive reaction of chemical purification, its pH value of 7-8, slightly alkaline. It covers the surface of friction materials and protects other materials from oxidation, especially making other materials less likely to fall off and increasing the adhesion.

Product Description

Fineness: 325 mesh – 2500 mesh;

PH value: 7-8;

Density: 4.8-5.0g/cm³;

Hardness: 1-1.5;

Loss on Ignition: 18-22%;

Friction Coefficient: 0.05-0.09.

Besides, molybdenum disulfide can be new material for making transistors. Molybdenum disulfide has an energy band gap of 1.8 eV compared to graphene, which is a two-dimensional material, while graphene has no energy bandgap. Moreover, the electron mobility of monolayer molybdenum disulfide transistors can reach up to about 500 cm^2/(V-s), and the current switching rate can reach 1×10^8.

Data Sheet

| Specification | M01 | M02 | M03 | M04 |

MoS2(%) ≥ | 98.5 | |||

| Average particle size | 16.0-30.0 | 12.0-16 | 3.0-6.0 | 1.3-1.5 |

| Acid insoluble substance(%)≤ | 0.50 | 0.50 | 0.50 | 0.50 |

| Molybdenum trioxide(%)≤ | 0.05 | 0.05 | 0.10 | 0.10 |

| Silicon dioxide (SiO2)(%)≤ | 0.10 | 0.10 | 0.10 | 0.10 |

| Iron(%) ≤ | 0.25 | 0.25 | 0.25 | 0.25 |

| Water(%) ≤ | 0.10 | 0.10 | 0.10 | 0.10 |

| Oil(%)≤ | 0.05 | 0.20 | 0.25 | 0.25 |

| Carbon(%)≤ | 0.50 | 0.50 | 0.50 | 0.50 |

| Acid value ≤ | 0.05 | 0.30 | 0.30 | 0.50 |

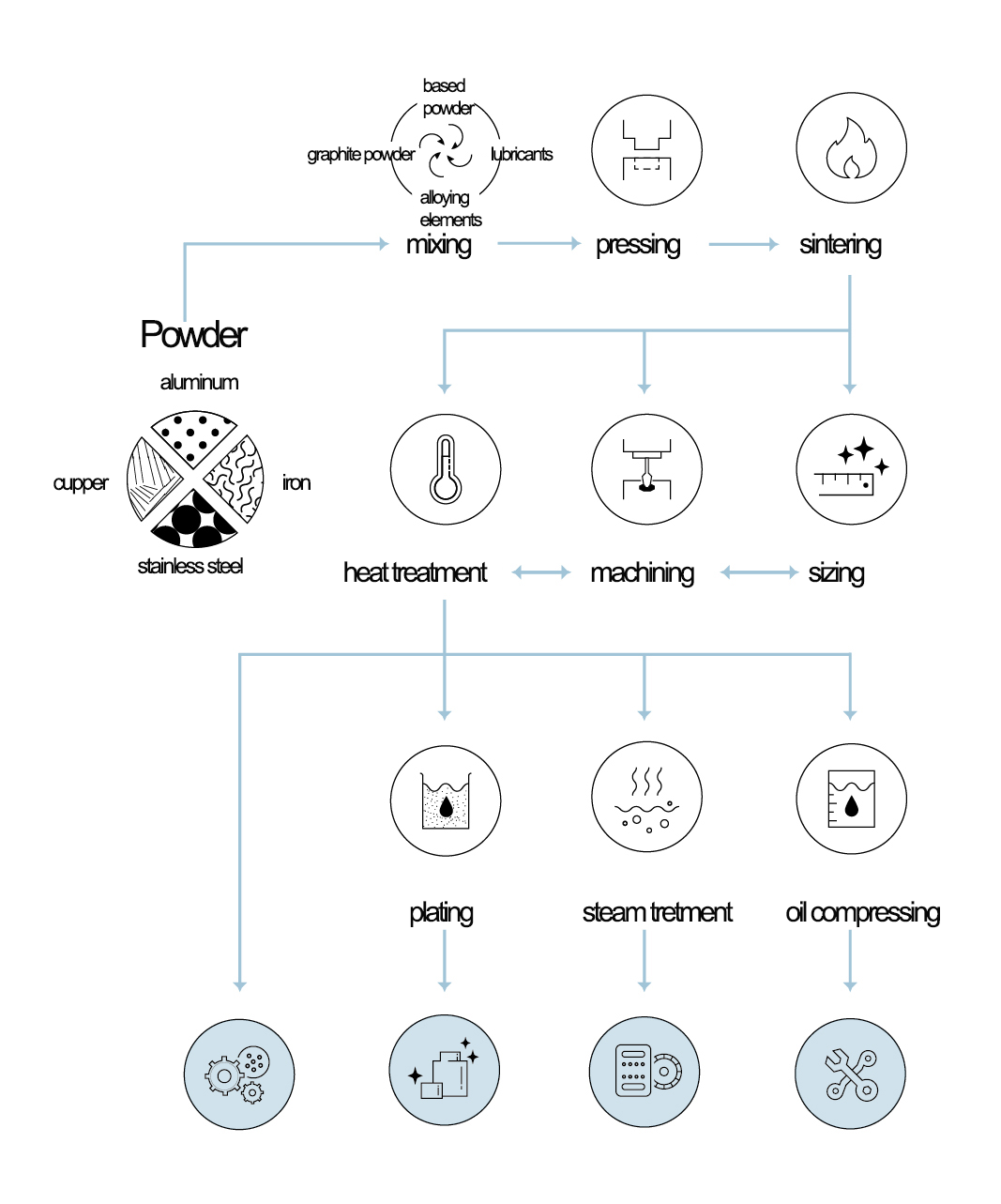

Production Process

About Truer

Shanghai Truer

Powder Metallurgy Additive Manufacturer

Shanghai Truer Industrial Development Co., Ltd. is an entity that integrates research and development, production, and sales. The excellent team is the cornerstone of our success, in 2007, we set up a research and development team, after in-depth research, Truer has set up two divisions, the Metallurgical Division and the Powder Metallurgy Additives Division.

TRUER Powder Metallurgy Additives Division is acknowledged to be one of the most professional additive suppliers in the Chinese powder metallurgy industry and committed to providing complete additive solutions to PM customers. TRUER has developed a variety of powder metallurgy, lubricants Lube-W, SUW-5000B, SUW-8000; cutting agent manganese sulfide, sulfur-free cutting agent SME-100, composite cutting agent TD-8; new soft magnetic additives QH-150; QHP-330 graphite TBC-400; TBC-1000 and so on. These raw materials are all supplied and customized by famous manufacturers

Production Process

TRUER Metallography Division TRUER Metallography is focusing on the production, development, and sales of metallographic equipment and consumables. TRUER has been committed to becoming the most professional supplier of metallographic equipment and consumables in China and the world. Through continuous exploration and development, we have successfully developed professional solutions for the analysis of different target materials and established a perfect product system, which covers metal, ceramics, electronics, plastics, and other major industries, and our high-quality products combined with perfect technical service are highly praised by the metallographic industry.

Solution Provider

Technical Certificates