CaF2

Industrial grade Calcium Fluoride Application

1. metallurgical industry: fluorite has the ability to reduce the melting point of refractory substances, promote slag flow, make slag and metal well separated, desulfurization in the smelting process, dephosphorization, enhance the metal calcined and tensile strength, and other characteristics. Therefore, it is widely used in iron and steel smelting and ferroalloy production, iron process, and non-ferrous metal smelting as a flux. Smelting fluorite ore with general requirements of calcium fluoride content greater than 65%, and the main impurity silica also has certain requirements, there are strict limits on sulfur and phosphorus. The content of sulfur and phosphorus shall not be higher than 0.3% and 0.08% respectively.

2. chemical industry: the main raw materials for the production of anhydrous hydrofluoric acid, the basic raw materials for fluorine chemicals (Freon, fluoropolymers, fluorine-containing fine chemicals).

3. Cement industry: the production of cement clinker mineralizer, can reduce the sintering temperature, easy calcination, burning time is short, save energy.

4. Glass industry: Raw materials for the production of emulsified, opaque and colored glass, which reduces the temperature of glass melting, improves the melt, and accelerates melting, thereby reducing the rate of fuel consumption.

5. Ceramic industry: the melting agent and emulsifier in the manufacture of ceramics and enamel, and is one of the indispensable components in the preparation of glaze.

Basic Parameters

| CaF2 | 95.4 (%) |

| SiO2 | 3.9 (%) |

| CaCO3 | 0.34 (%) |

| Moisture | 0.35 (%) |

| Density | 3.1-3.2 (g/cm3) |

| 100 mesh pass rate | 93 (%) |

| Color | Green, blue, brown, yellow, pink, purple, colorless, etc. |

| Melting point | 1270-1350 (°C) |

Packaging and Transportation

This product is a white powder, packing: large ton pack. Store in a dry and ventilated place, moisture-proof.

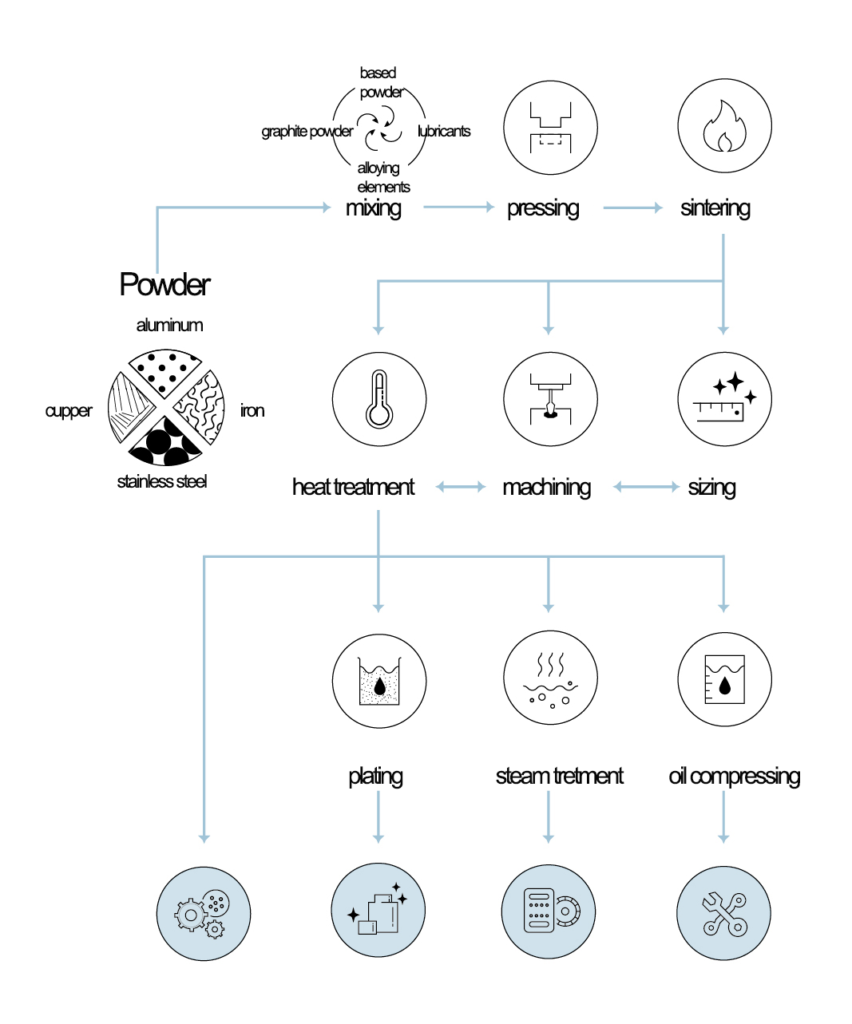

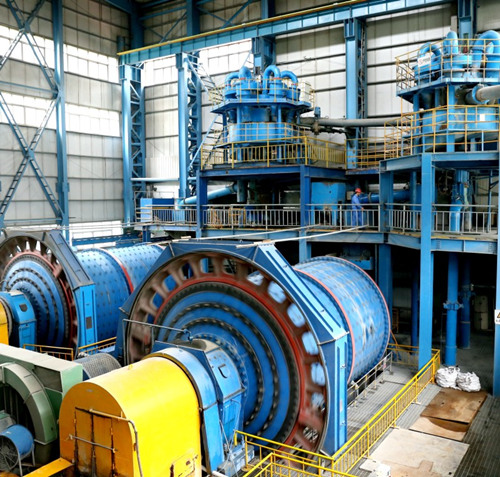

Production Process

About Truer

Shanghai Truer

Powder Metallurgy Additive Manufacturer

Shanghai Truer Industrial Development Co., Ltd. is an entity that integrates research and development, production, and sales. The excellent team is the cornerstone of our success, in 2007, we set up a research and development team, after in-depth research, Truer has set up two divisions, the Metallurgical Division and the Powder Metallurgy Additives Division.

TRUER Powder Metallurgy Additives Division is acknowledged to be one of the most professional additive suppliers in the Chinese powder metallurgy industry and committed to providing complete additive solutions to PM customers. TRUER has developed a variety of powder metallurgy, lubricants Lube-W, SUW-5000B, SUW-8000; cutting agent manganese sulfide, sulfur-free cutting agent SME-100, composite cutting agent TD-8; new soft magnetic additives QH-150; QHP-330 graphite TBC-400; TBC-1000 and so on. These raw materials are all supplied and customized by famous manufacturers

Production Process

TRUER Metallography Division TRUER Metallography is focusing on the production, development, and sales of metallographic equipment and consumables. TRUER has been committed to becoming the most professional supplier of metallographic equipment and consumables in China and the world. Through continuous exploration and development, we have successfully developed professional solutions for the analysis of different target materials and established a perfect product system, which covers metal, ceramics, electronics, plastics, and other major industries, and our high-quality products combined with perfect technical service are highly praised by the metallographic industry.

Solution Provider

Technical Certificates