Duplex stainless steel powder 2205, 2507 & 2707

With the rapid development of additive manufacturing technology represented by 3D printing, super duplex stainless-steel has begun to be applied in various fields such as Marine, chemical and petroleum. The precise and controllable chemical composition of duplex stainless-steel powder is the basis and difficulty of the preparation of this kind of powder. From the perspective of production practice, this paper analyzes in detail how to break through the key technologies to achieve stable mass production.

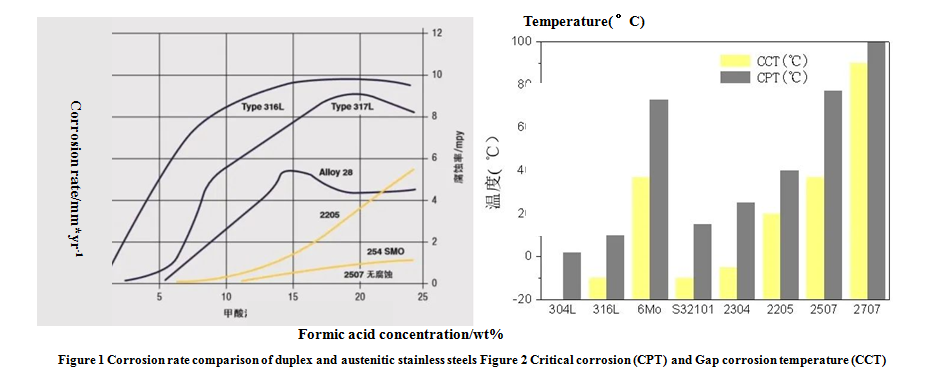

Duplex Stainless Steel (DSS) is a multiphase structural metal material consisting of a comparable volume fraction of ferrite (α) and austenite (γ). It integrates the advantages of ferritic stainless steel and austenitic stainless steel, with excellent corrosion resistance, high strength and good plasticity.

Table 1 shows the chemical composition of typical duplex stainless steels 2205, 2507 and 2707, and Table 2 shows the mechanical properties of these typical stainless steels.

| Grade | UNS No. | EN No. | C | Cr | Ni | Mo | Cu | N |

| 2205 | S32205 | 1.4462 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | 3.0-3.5 | – | 0.14-0.20 |

| 2507 | S32507 | 1.441 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | ≤0.5 | 0.24-0.32 |

| 2707 | S32707 | ≤0.03 | 26.0-29.0 | 5.5-9.5 | 4.0-5.0 | ≤1.0 | 0.30-0.50 |

Table 1 Chemical composition of 2205, 2507, 2707 (wt%)

| UNS No. | Rp0.2/Mpa(ksi) | Rm/Mpa(ksi) | δ/% | EN No. | Rp0.2/Mpa(ksi) | Rm/Mpa(ksi) | δ/% | |

| 2205 | S32205 | 450(65) | 655(95) | 25 | 1.4462 | 460(67) | 640(93) | 25 |

| 2507 | S32507 | 550(80) | 795(116) | 15 | 1.441 | 530(77) | 730(106) | 20 |

| 2707 | S32707 | 580(84) | 850(124) | 25 | 570(83) | 845(123) | 25 |

Table 2 Mechanical properties of 2205, 2507, 2707

With the increasing advancement of energy and environmental protection issues, the shell and blade of the turbine in the tidal power generation equipment, the valve in the nuclear power plant, and the impeller in some desulfurization devices are mostly using cast duplex stainless steel. But some duplex stainless-steel castings with complex structure is difficult to castwhich limits its development.

Compared with traditional casting processes, the advantage of 3D printing is the ability to freely manufacture complex parts directly from powders, without involving traditional manufacturing methods such as extrusion, forging, casting and secondary processing to obtain the desired shape, and the mechanical properties of the material can meet or exceed the casting level.

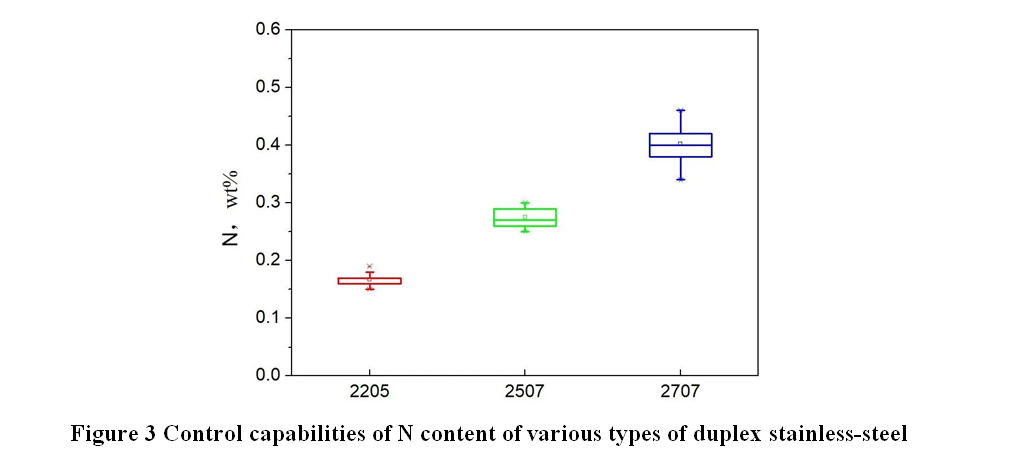

It is understood that Truer Technology Co., Ltd. has started the research and development of a series of duplex stainless steel powder since 2021. This kind of duplex stainless steel has a high N content and a narrow composition interval, and how to accurately and stably control the N content in the alloy is also a technical challenge.

Based on the thermodynamic and kinetic calculations of N alloying, TruerStainless steel powder RD team formulated an adjustable N alloying control process to get stable and accurate N control. The control level of the series of N-containing duplex stainless-steel produced by Truer is shown in Figure 3,and the N content of all types of duplex stainless steel in all furnaces is controlled within the target range. N content of 2205 can be stably controlled between 0.16~0.19 wt%, N content of 2507 between 0.26~0.30 wt%, 2707 between 0.42~0.46 wt%.

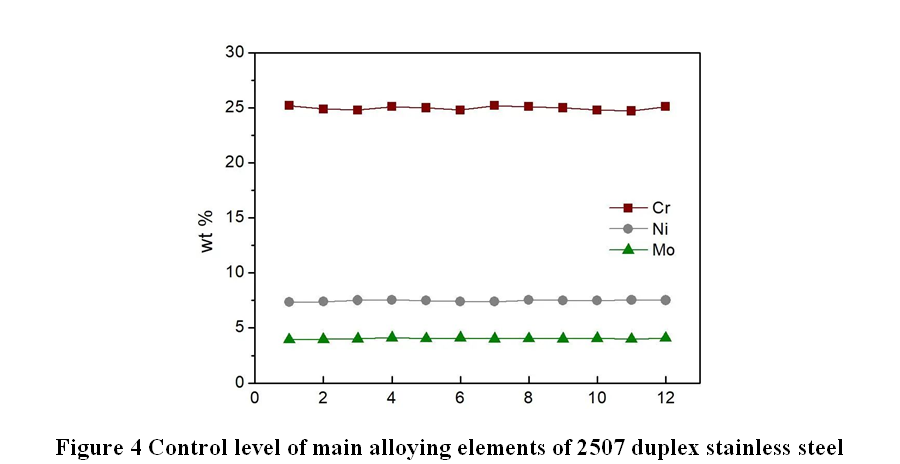

Figure 4 shows the changes of main alloying elements in different furnaces of 2507 duplex stainless steel produced by Truer. It showed the content of various alloying elements is basically the samein different furnace, showing good smelting control ability.

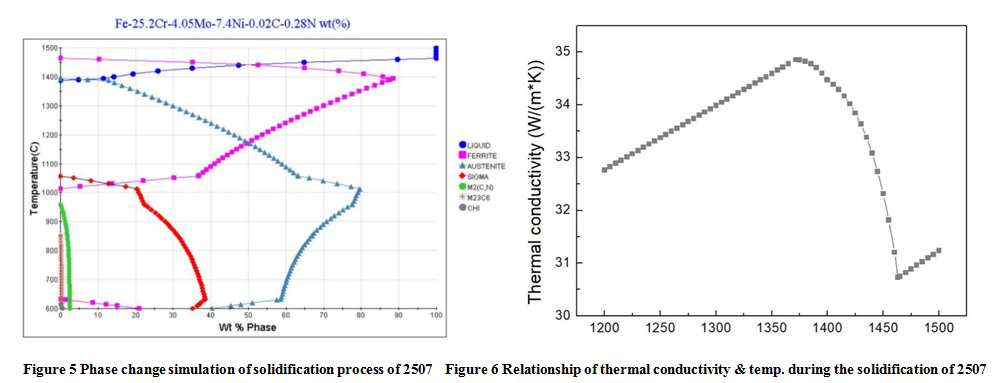

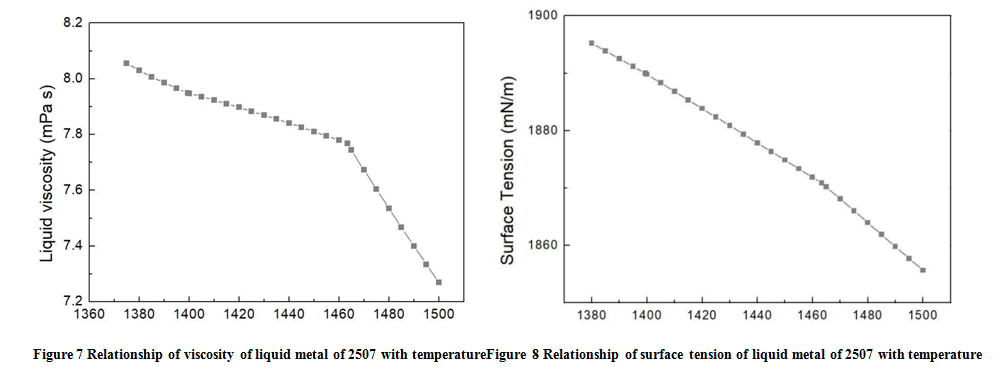

For this reason of alloying elements control, Truer stainless steel powderRD team developed data-driven atomization technology, completed the simulation calculation of parameters including the phase transition during solidification, the change of thermal conductivity during solidification, and the physical properties of liquid metal (viscosity, surface tension), and established a full set of “physical properties of metal solidification process”, which provides complete data support for the gas atomization of duplex stainless steel.Figures 5-8 shows the simulation results of the correlation physical properties of 2507 duplex stainless steel.

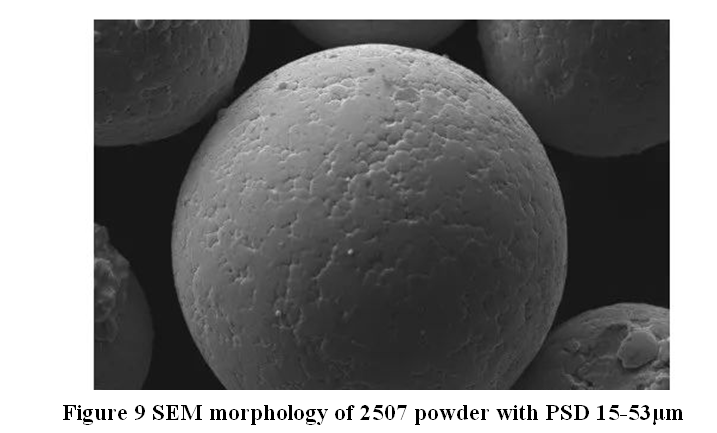

Figure 9 shows the SEM morphology of 2507 super duplex stainless steel powder with PSD 15-53μm produced by Truer. The powder has good sphericity, smooth surface and few satellite balls. And Table 3the physical propertiescomparison of different grades ofduplex stainless steel powders. It showed particle size (15-53um) control is very stable (D10:18-23um, D50:32-36um, D90:52-56um).

| Grade | UNS No. | Size Distribution | Flowability(s/50g) | Apparent Density(g/cm³) | Tap Density(g/cm³) |

| 2205 | S32205 | D10/um:21.6 D50/um:34.7 D90/um:54.3 | 20 | 4.20 | 4.73 |

| 2507 | S32507 | D10/um:20.3 D50/um:32.9 D90/um:52.4 | 19.8 | 4.18 | 4.7 |

| 2707 | S32707 | D10/um:20.5 D50/um:33.1 D90/um:53.5 | 19.6 | 4.16 | 4.68 |

Table 3 Physical properties of different duplex stainless steel powder with PSD 15-53um

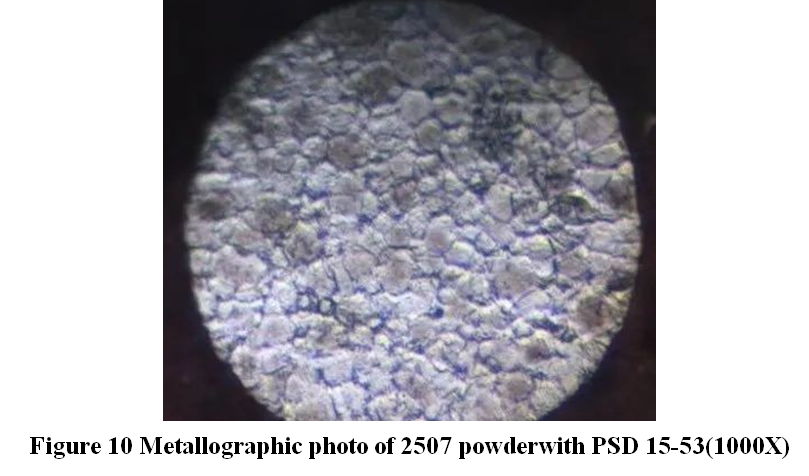

The research and development team of stainless steel powdersalso carried out metallographic inspection of the duplex stainless-steel powder. Figure 10 shows the etching state of powder in 2507 powder with PSD 15-53μm. It can be clearly observed from the figure that the powder inside is uniform equiaxial crystal structure.

Truersuccessfully realized the serial dual-phase stainless steel batch and stable production contributing tosome research and development, including alloying computer-aided design, atmosphere adjustable alloying process, data-driven customized gas atomization and other integrated control technology.

Truer has developed and produced a series of high-end powder products such as nickel-based superalloy Inconel 738LC, CMSX-4, Haynes 230, Hastelloy B, Monel 400, BNi-7, NiCrAlY, Nitinol NiTi50, Invar 36, Co-based superalloy Triballoy T800, Haynes 188, and high-entropy alloy FeCoCrNiMn, AlCoCrFeNi, FeCoNiCrTi, WMoTaNbZr, FeCoNiCrV, CoCrNiand so on.