Different kinds of cutting agent containing 0.4% of FC0205 powder were added on the basis of FC0205 powder to compare their effects on material properties. The forming density of the sample was 7.0 g/m³.

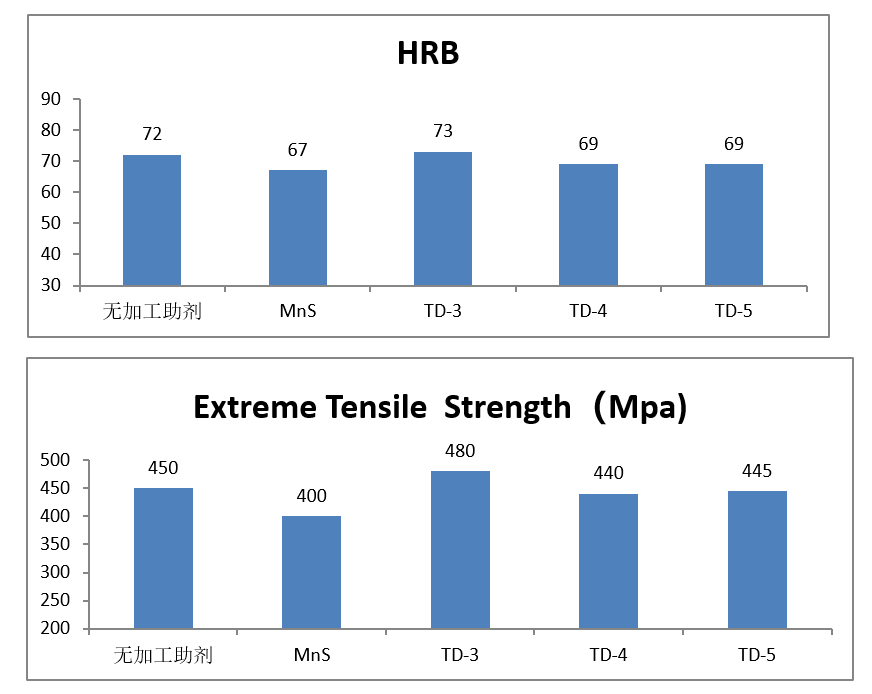

I. Effect on mechanical properties

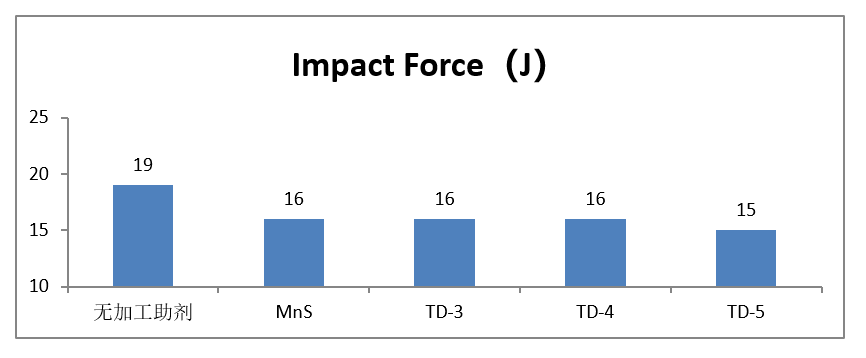

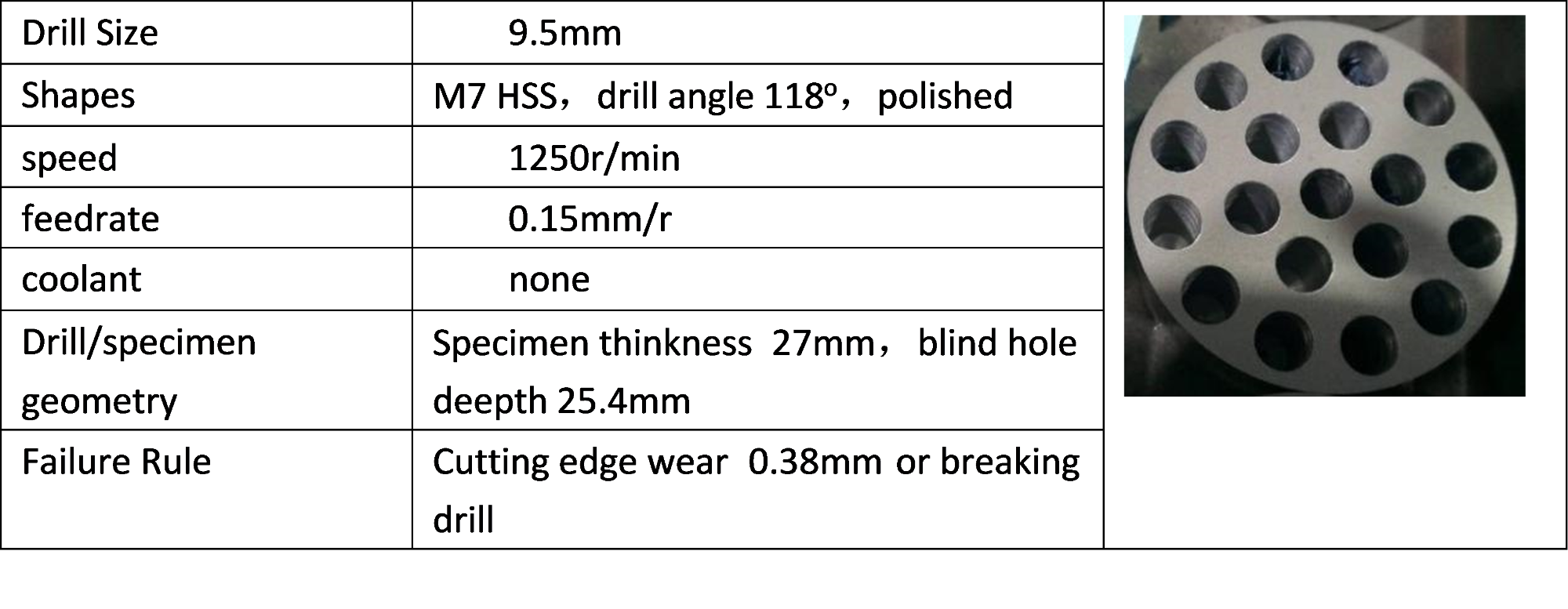

Impact on cutting performance: TD-3 and TD-4 have greatly improved the cutting performance of the material.

Cutting test conditions:

Sample diameter Φ70mm, hole to hole spacing of 3mm, 19 holes drilled per sample.

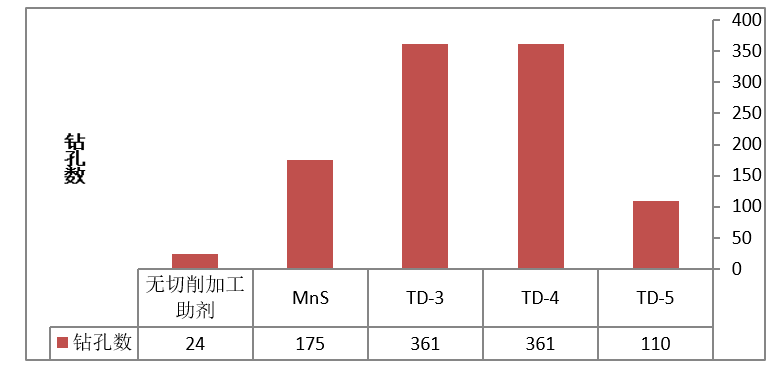

Third, the effect on the microstructure: no effect on the metallographic organization, pearlite content normal.

Contains no cutting aids Contains MnS

TD-3 TD-4

TD-5