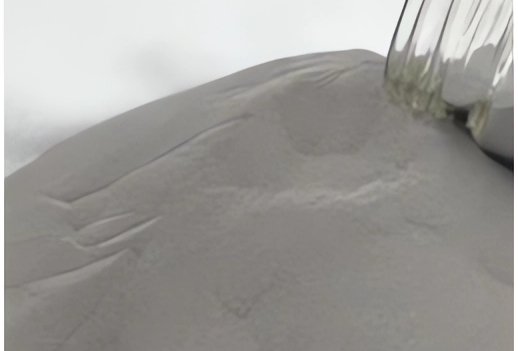

SMA powder┃Fe–17Mn–5Si–10Cr–4Ni

Shape memory alloys fabricated by additive manufacturing, known as three-dimensional (3D) printing, , comparable the conventional fabrication method, such as casting and rolling, showed higher shape memory effect (SME).

The particle size distribution of our gas-atomized spherical Fe–17Mn–5Si–10Cr–4Ni (wt.%) shape memory alloy (Fe-SMA) powder for L-PBF process is 15-53um.

After a series of experiments conducted by R&D department of Truer, it has been proven that post-heat treatment on the microstructure and shape memory properties of printed partsby our 15-53um powders has some clear impacts, concluding the best combination of the post-heat-treatment temperature and time to the highest recovery strain is about 800 °C for 0.5 h.

Chemical Composition:

| CHEMICAL COMPOSITION (wt%) | |||||

| Fe | Mn | Si | Cr | Ni | |

| Min | Bal | 15.5 | 4.0 | 9.0 | 3.5 |

| Max | Bal | 18.5 | 6.0 | 11.0 | 5.5 |

Particle Size Distribution:

| PARTICLE SIZE DISTRIBUTION (wt%) | |||

| D10 | D50 | D90 | |

| Min | 15 | 28 | 50 |

| Max | 25 | 37 | 58 |

We also can provide other particle size distribution by sieving.

We pack the powders by plastic cans or vaccum aluminium foils.