Home » Titanium based alloy powder » Ti6Al4V Powder

Ti6Al4V Powder

Ti6Al4V (TC4) is a double-phases alloy, well-known light alloy (lower specific weight) with exceptional chemical stability, corrosion resistance, bio-compatibility, and mechanical properties (good ductility, good strength at the wide temperature range (-253~500℃)). Its strength is similar to steel but only half of the specific weight.

Spherical Ti6Al4V metal powders are ideal for high-performance applications due to its outstanding characteristics as mentioned above, like Aerospace, Military, Biomedical and Industrial markets, which can be produced by many different production processes, like Electrode Induction Gas Atomizing (EIGA), Plasma Spheridizing Atomizing (PA), Plasma Rotating Electron Process (PREP), etc.

| CHEMICAL COMPOSITION (wt%) | |||

| Element | Min | Max | Standard |

| Ti | Bal | – | ASTM B348 or ASTM F136 or ASTM F1580 or ASTM F2924 or ASTM F3001 |

| Al | 5.50 | 6.75 | |

| V | 3.50 | 4.50 | |

| O | – | 0.20 | |

| C | – | 0.08 | |

| N | – | 0.05 | |

| H | – | 0.015 | |

| Fe | – | 0.40 | |

| Others, each | – | 0.10 | |

| Others, total | – | 0.40 | |

| Particle size | |||

| Type 1 | 0-25μm | ASTM B214 or ISO 13320 or ASTM B822 | |

| Type 2 | 0-45μm | ||

| Type 3 | 15-45μm | ||

| Type 4 | 15-53μm | ||

| Type 5 | 45-106μm | ||

| Type 6 | 53-150μm | ||

| Type 7 | Customized, can be sieved per customer’s specification | ||

| Other properties | |||

| Hall flow | These properties links to the manufacturing methods, can be provided after contract signing. | ||

| Apparent density | |||

| Tap density | |||

| Morphology | |||

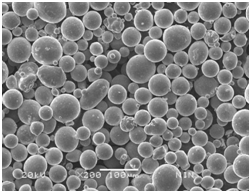

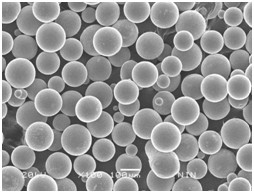

| Typical SEM picture(s) | |||

|

|

||

| Produced by EIGA | Produced by PREP | ||