Table of Contents

ToggleTungsten metal powder is a fine particulate form of tungsten used as a raw material in various industrial applications. Its unique properties like high density, strength, corrosion resistance and high melting point make it an important engineering material.

Composition and Manufacturing

| Parameter | Details |

|---|---|

| Elemental Composition | Pure tungsten (W) or an alloy with other metals |

| Production Process | Milled from tungsten rods or reduced from tungsten oxides |

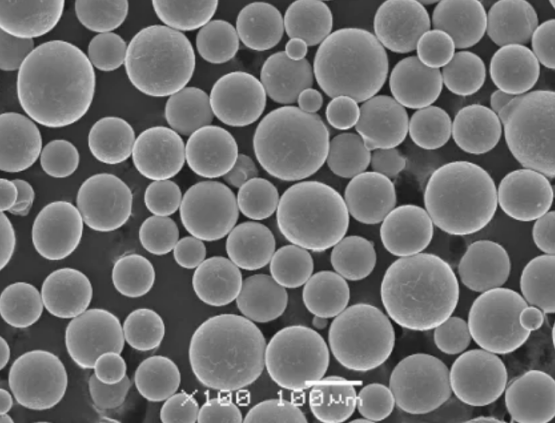

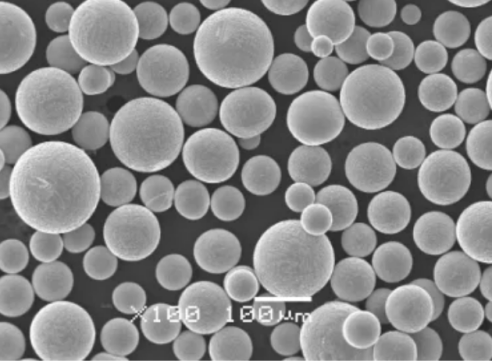

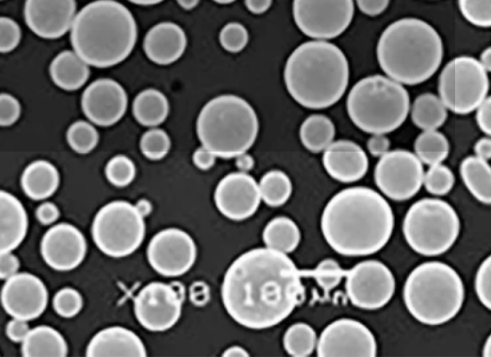

| Particle Sizes | Ranging from 1 micron to 150 microns typically |

| Purity Grades | From 99% to 99.995% pure tungsten |

Tungsten powder is produced through various processes like hydrogen reduction, milling, or thermal plasma spheroidization to achieve desired shape and purity.

Properties and Characteristics

| Property | Value |

|---|---|

| Density | 19.3 g/cm3, almost twice that of steel |

| Melting Point | 3422 °C, highest of all metals |

| Strength | Very high hardness and strength, especially when sintered |

| Conductivity | Low electrical resistivity, high thermal conductivity |

| Stability | Excellent chemical stability and corrosion resistance |

These unique properties lend tungsten metal powder to various specialty applications.

Applications and Uses of tungsten metal powder

| Application | Usage |

|---|---|

| cemented carbide tools | binded in cobalt matrix for cutting tools |

| Counterweights | High density ideal for weights and ballast |

| Radiation Shielding | Effective shield from X-ray/gamma sources |

| Thermionic Emitters | Filaments due to high melting point |

| 3D Printing Powders | For printing high-strength tungsten parts |

Tungsten powder supports mission-critical needs across defense, medical, aerospace, and other industries.

Specifications and Standard Grades

Tungsten powder is available under various international standards that define particle size distribution, purity levels, manufacturing method etc. Some common specifications include:

- ASTM B772 – Pure tungsten powder types

- ISO 5453 – Chemical analysis and size classification

- ICDD 00-001-1202 – Crystalline structure reference

Suppliers and Pricing

| Supplier | Price per kg |

|---|---|

| Midwest Tungsten | $70 – $500 |

| Buffalo Tungsten | $100 – $600 |

| Tungsten Heavy Powder | $150 – $800 |

| Global Tungsten Powders | $250 – $1500 |

Pricing depends heavily on purity grade, particle shape/size consistency, quantity ordered, and value-added processing.

Pros vs Cons

| Pros | Cons |

|---|---|

| Exceptional hardness and density | Expensive compared to alternatives |

| Withstands high temps | Heavy – adds weight if used in products |

| Corrosion and wear resistant | Brittle if not properly processed |

| Environmentally stable | Difficult to machine in certain forms |

| Uniform particle distribution | May require protective atmospheres |

FAQs

What is tungsten metal powder used for?

It has applications in tools, weights, radiation shielding, electronics, 3D printing, and other high-performance domains due to its specialized properties.

What purity grades are available?

Common purity levels range from 99% to 99.995%. Higher purity commands much higher pricing.

What is the typical particle size?

Particle size can range from 1 micron to 150 microns. Desired size depends on application method and end-use requirements.

Is tungsten environmentally hazardous?

No. Tungsten metal powder is generally non-toxic and eco-friendly. Certain processing may use hazardous compounds requiring care.