Table of Contents

ToggleIron powder is a powdered form of elemental iron. It is commonly used in many industrial and manufacturing applications due to its unique properties and versatility. This comprehensive guide will provide an overview of iron powder, its types, characteristics, applications, design considerations, suppliers, installation, operation and maintenance.

Overview of Iron Powder

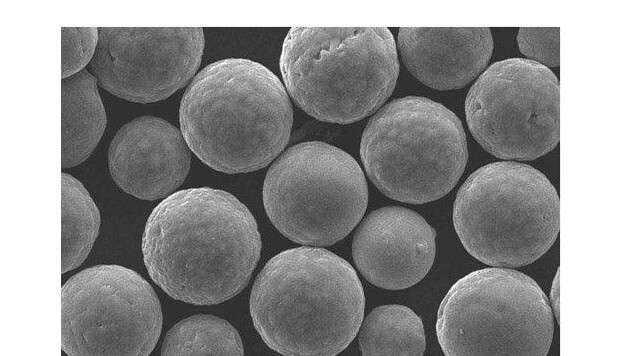

Iron powder is composed of small particles of iron that have been pulverized into a fine powder. The particles are typically spherical or irregularly shaped and range in size from 10-150 microns.

Iron powder is highly magnetizable and exhibits high permeability. It also has a relatively high density compared to other metal powders. Additionally, iron powder displays excellent electromagnetic properties.

Some of the key properties of iron powder include:

- High magnetizability and permeability

- Density of 7.86 g/cm3

- Melting point of 1538°C

- Excellent compressibility into parts

- Good thermal and electrical conductivity

- Oxidation resistance

- Low manufacturing cost

Iron powder is available in various grades which differ in purity, particle size distribution, and production method. The major types of iron powder include:

- Carbonyl iron powder

- Electrolytic iron powder

- Reduced iron powder

- Atomized iron powder

The most common production methods for iron powder are carbonyl decomposition, electrolysis, and atomization.

Iron powder has become an increasingly important material across many industries due to its versatility. It is used in a diverse array of applications including:

- Powder metallurgy

- Brazing and welding

- Magnets

- Electromagnetic shielding

- Friction products

- Filtration

- Radio frequency absorption

- Microwave absorption

- Pigments and powder coatings

- Magnetic ink printing

- Food fortification

- Pharmaceuticals

The selection of the appropriate grade and type of iron powder depends on the specific application and desired properties.

Types of Iron Powder

There are several different types and grades of iron powder that are commercially available. The major types include:

Carbonyl Iron Powder

- Produced by decomposition of iron pentacarbonyl

- High purity (>99% Fe)

- Spherical particle morphology

- Smooth particle surface

- Tight particle size control

- Soft magnetic properties

- Used in high performance applications

Electrolytic Iron Powder

- Produced by electrolysis of iron chloride or sulfate

- Irregular sponge-like particle shape

- Broad particle size distribution

- High apparent density

- Lower cost

- Used in general powder metallurgy

Reduced Iron Powder

- Produced from mill scale or iron ore

- Sponge-like porous structure

- Annealed to improve properties

- Lower purity (~95% Fe)

- Lower cost

- Used in less demanding applications

Atomized Iron Powder

- Produced by atomization of molten iron

- Irregular shaped particles

- Oxidized surface

- Large particle size distribution

- Used in powder metallurgy

Alloyed Iron Powder

- Contains alloying elements like nickel, copper, molybdenum

- Enhanced properties

- Used for high performance powder metallurgy

Insulated Iron Powder

- Iron powder particles coated with insulating layer

- Used for electromagnetic applications

Characteristics of Iron Powder

Iron powder is available in many different grades. Key characteristics used to differentiate grades include:

Particle Size

- Size range from 10 – 150 microns

- Smaller sizes have greater surface area

- Larger sizes provide higher density

- Size influences compressibility, permeability, flowability

Purity

- Carbonyl iron has highest purity >99%

- Other grades contain 85-95% iron

- Impurities affect magnetic properties

Particle Shape

- Carbonyl and atomized are spherical

- Electrolytic and reduced are sponge-like

- Shape impacts density and flowability

Apparent Density

- Ranges from 1 – 5 g/cm3

- Higher density provides greater weight loading

- Affects compressibility and permeability

Flowability

- Influenced by particle size, shape, and surface roughness

- Important for handling and processing

- Measured by Hall flowmeter funnel test

Compressibility

- Ability to compress iron powder into shapes

- Affected by morphology, size, purity, density

- Green strength determines ability to handle parts

Applications of Iron Powder

Iron powder has become an indispensible advanced material thanks to its exceptional properties and ease of manufacturing into both simple and complex parts and products.

Powder Metallurgy

The most common application is in powder metallurgy to produce precision parts including:

- Gears

- Bearings

- Filters

- Magnets

- Hard metal tools

- Structural components

Iron powder can be compressed and then sintered to form high density parts with close tolerances and net shape. This avoids wasteful machining required for wrought or cast parts. The fine iron powder particles fuse together during sintering providing good strength. Parts can also be infiltration strengthened or steam treated after sintering.

Alloy grades of iron powder can produce specialized components with enhanced wear resistance, friction, and other properties. Insulated grades are important for producing soft magnetic components used in electric motors and generators.

Brazing and Welding

Finely divided iron powder can be used to facilitate brazing and welding of iron and steel. The iron powder melts and alloys with the base metal providing stronger joints. It acts as a filler material and fluxing agent during high temperature joining.

Magnets

Compacting iron powder with binder and then magnetizing forms permanent magnets that are used in motors, sensors, and actuators. Soft magnetic cores for inductors and transformers are also made from iron powder as a powder metallurgy component.

Electromagnetic Shielding

Mixing iron powder in a polymer matrix provides electromagnetic interference (EMI) and radio frequency interference (RFI) shielding by attenuating electromagnetic waves. The composite material can be injection molded into enclosures and housings for electronics.

Friction Materials

Iron powder is commonly used in brake pads, clutch facings, and other friction products. It provides mechanical strength and thermal stability. Small amounts of iron powder can enhance friction without increasing wear.

Filtration Media

Pressed and sintered iron powder filter elements have a porous structure suitable for collecting fine particles from liquids and gases. Used in hydraulic systems, engine oil, air compressors, and vacuum cleaners.

Microwave Absorption

Iron powder absorbs microwave radiation and converts it into thermal energy. It is used in microwave heating applications. Insulated iron powder is particularly effective due to its high microwave loss.

Food Fortification

Iron powder is used to fortify flour and cereal products as a means of reducing iron deficiency. The fine powder adheres uniformly to the food and does not affect taste or appearance.

Pharmaceuticals

Iron powder is used in some dietary supplements and drugs for treatment of iron deficiency anemia. Due to the elemental nature, iron powder has high bioavailability.

Pigments

Iron oxide pigments are produced by oxidizing iron powder. Used in paints, plastics, rubber, ceramics, and other materials needing coloration. Provides yellow, red, black, or brown shades.

Iron Powder Specifications

Iron powder is available in standard grades but can also be customized to meet application requirements. Typical specifications for iron powder include:

Iron Powder Types and Grades

| Type | Grade | Purity | Size (μm) | Shape | Apparent Density (g/cm3) |

|---|---|---|---|---|---|

| Carbonyl | HQ | >99% | 3-6 | Spherical | 4-5 |

| Carbonyl | SF | >99% | 10-15 | Spherical | 2-3 |

| Electrolytic | ABC | >98% | 20-180 | Sponge | 2.5-4 |

| Electrolytic | ATOMET | >99% | 150-300 | Sponge | 4-5 |

| Reduced | RB | >85% | 20-180 | Porous | 2-3 |

| Atomized | ATO | >99% | 20-150 | Irregular | 3-4 |

Typical Impurities

- Carbon: 0.01-0.8%

- Oxygen: 0.2-2%

- Nitrogen: 0.001-0.02%

- Sulfur: 0.005-0.05%

Packaging

- 1 lb to 50 lb plastic bottles or drums

- 100-500 lb boxes with moisture barrier lining

- 1000+ lb super sacks

Storage

- Store sealed containers in cool, dry, indoor environment

- Avoid temperature extremes and humidity

- Desiccant bags recommended to prevent oxidation

Precautions

- Explosion hazard – keep away from ignition sources

- Avoid inhalation of fine powder

- Use spark-proof tools for handling

Iron Powder System Design

Proper design of iron powder handling systems and equipment is necessary for safe and effective use in manufacturing operations. Important design considerations include:

Containment

- Use sealed containers, piping, and dust collection to prevent powder releases

- Containment systems must withstand 30-45 psi relief pressures

- Access points should have dust-tight seals

Explosion Prevention

- Use inert gas blanketing to prevent oxygen contact

- Avoid ignition sources like sparks, heat, and static discharge

- Employ explosion suppression systems

- Ground all equipment to minimize static charge buildup

Ventilation

- Local exhaust ventilation required in powder handling areas

- Dust collectors must have sufficient capacity and air flow

- HEPA filtration preferred to capture fine particles

Fire Safety

- Use noncombustible construction materials

- Separate powder operations from other areas

- Install automatic fire detection and suppression systems

Equipment

- Select equipment suited for iron powder characteristics

- Consider capacity, flowability, abrasiveness, packing

- Design for easy cleaning and sanitation

Controls

- Automated controls for material handling preferred

- Level sensors, flow monitors, pressure indicators

- Interlocks for critical safety functions

Proper iron powder system design is crucial for performance, safety, and regulatory compliance. Expert input from vendors and consultants is recommended when designing powder handling systems and equipment.

Iron Powder Suppliers

Iron powder is produced by metals companies globally and is readily available from many commercial suppliers and distributors.

Leading Iron Powder Manufacturers

| Company | Location |

|---|---|

| Hoganas | Sweden |

| Rio Tinto Metal Powders | Canada |

| JFE Steel Corporation | Japan |

| Wuhan Iron & Steel Corporation | China |

| BASF | Germany |

| Sandvik Osprey | United Kingdom |

| CNPC Powder | China |

Iron Powder Distributors

- Belmont Metals

- Micron Metals

- Industrial Metal Powders

- American Elements

- Reade Advanced Materials

- Höganäs North America

When selecting an iron powder supplier, important factors to consider include:

- Technical expertise with iron powder applications

- Ability to customize powder characteristics

- Production capacity and lead times

- Inventory availability for short delivery times

- Consistent quality and strict quality control

- Competitive pricing and minimum order quantities

- Responsiveness and customer service reputation

It is recommended to test material from any new supplier in your manufacturing process to qualify performance before buying large quantities. Request samples of powder grades of interest for evaluation.

Iron Powder Prices

Iron powder pricing depends on several factors:

Type and Grade

- Carbonyl powder is most expensive due to high purity

- Electrolytic and atomized grades have mid-range pricing

- Reduced iron grades have lowest cost

Quantity

- Prices are highest for small quantity orders

- Bulk quantities of tons or more provide best pricing

- Negotiable pricing for very large annual volumes

Quality

- Higher purity and tighter control demands higher prices

- Premium grades cost more than commodity grades

Supplier

- Major global suppliers offer competitive pricing

- Local distributors may have smaller minimums

- Delivery logistics impact final costs

Typical Iron Powder Price Ranges

| Grade | Price per Pound |

|---|---|

| Carbonyl | $3 – $8 |

| Electrolytic | $1 – $5 |

| Reduced | $0.5 – $2 |

| Atomized | $1 – $3 |

Prices vary over time based on raw material costs, supply and demand. Annual purchase contracts can lock in better iron powder pricing.

Installing Iron Powder Systems

Proper installation of iron powder handling systems is critical for performance and safety. Here are some best practices:

Site Preparation

- Floors must be sealed concrete without cracks

- Walls should be smooth finish without ledges

- Optimal lighting, ventilation, sprinkler systems

- Dedicated room separate from other operations

Receiving and Inspections

- Inspect delivered equipment for any damage

- Verify models match approved drawings

- Check motor nameplates for electrical ratings

Positioning

- Review layout drawings for proper positioning

- Allow access for operation, maintenance, cleaning

- Check clearances to walls, ceilings, other equipment

Assembly

- Assemble modular components per manufacturer instructions

- Use calibrated torque wrenches for all bolted connections

- Check alignments and clearances

Electrical Connections

- Confirm power supply matches equipment ratings

- Use skilled electricians for all wiring work

- Double check phase sequence for motors

Dust Collection

- Install ducting per prescribed routes

- Secure gasketed fittings to prevent leaks

- Check air flow at pick-up points meets design

Control Connections

- Terminate all sensors, actuators, networks

- Label wiring according to schematics

- Ground all components properly

Commissioning

- Verify all safety features fully functional

- Perform control loops tuning

- Confirm desired system performance before starting production

Follow all equipment manufacturer installation instructions closely. Have factory technicians inspect critical powder handling equipment after installation.

Operating Iron Powder Equipment

Safe and efficient operation of iron powder processing equipment requires proper procedures and training.

Safety

- Require personal protective equipment – respirators, gloves

- Ensure adequate ventilation and dust collection

- Follow lockout/tagout, confined space protocols

- Eliminate ignition sources – no smoking near powder

Loading

- Wear PPE when handling powder containers

- Carefully empty containers into feed hoppers

- Avoid spills – contain and clean any releases

Startup/Shutdown

- Energize ancillary equipment like dust collectors first

- Start main equipment gradually – check for anomalies

- Run cleaning cycles prior to shutdown

- De-energize in reverse order

Processing

- Monitor all sensors – pressure, temperature, flow

- Make incremental control adjustments

- Stop immediately if abnormal conditions arise

Sampling

- Collect periodic samples per written procedures

- Test samples in lab for quality control

Maintenance

- Inspect equipment routinely for issues

- Lubricate, adjust, or replace components as needed

- Follow detailed manufacturer maintenance guides

Housekeeping

- Keep areas clean from powder accumulation

- Clean equipment surfaces regularly

- Vacuum or wet mop floors

Document all operating parameters, production rates, downtime events, maintenance repairs, and inspections. Update procedures and training as needed.

Maintenance of Iron Powder Equipment

Consistent maintenance helps maximize production uptime and equipment lifetime when processing iron powder.

Routine Maintenance

- Visual inspections for damage, leaks, unusual wear

- Fastener tightness checks

- Drive alignment verification

- Oil and filter changes per schedule

- Lubrication of bearings, slides, chains

- Instrument calibration

- Dust collector filter cleaning

Breakdown Maintenance

- Troubleshoot issues – sensory input, data logs

- Disassemble equipment for repair access

- Replace damaged components – shafts, seals, liners

- Refurbish parts if feasible

Preventive Maintenance

- Schedule partial disassemblies for internal inspection

- Proactively replace wear components – hoses, gaskets

- Hardness testing of impact surfaces

- Alignments and balancing

- Ultrasonic testing for cracks

Upgrades/Retrofits

- Install updated control software

- Replace obsolete components

- Convert motors/drives to increase output

- Add instrumentation to enhance control

Spare Parts

- Keep stock of common wear parts

- Have backup motors/drives in inventory

- Replace used parts to maintain inventory

Follow manufacturer maintenance manuals. Record all repairs and parts replacements. Schedule major repairs during planned production shutdowns.

Choosing an Iron Powder Equipment Supplier

Selecting qualified iron powder equipment suppliers is key for success. Recommended selection criteria:

Industry Experience

- Years of experience supplying the iron powder industry

- Knowledge of equipment design considerations

- Installation references of similar powder plants

Technical Expertise

- Staff engineers skilled in bulk solids material handling

- Capability of complex custom design-builds

- Provide equipment layout and sizing services

Range of Equipment

- Provide nearly all required system components

- Capability for integrated, turnkey powder handling systems

Manufacturing Capabilities

- Modern facilities and production technology

- Skilled craftsmanship and quality control

- Able to produce large capacity equipment

Safety Focus

- Design equipment to mitigate powder hazards

- Integration of explosion protection features

- Expertise in safety standards compliance

After-sales Support

- Offer installation and maintenance services

- Long-term operation and maintenance training

- Readily available spare parts supply

Global Presence

- Sales and service support across regions

- Local offices provide rapid response

Financial Stability

- Well-established company with years in business

- Strong revenue and profitability

- Able to take on large contracts

Reputation

- Positive references from current customers

- Case studies of successful projects

Leading iron powder equipment suppliers include companies such as Gloucester Engineering, Gericke, and Dec. Schedule plant tours and product demonstrations when evaluating suppliers. Verify their expertise suits your specific project scope and requirements.

Iron Powder Equipment Pros and Cons

There are advantages and limitations to consider when selecting iron powder processing equipment:

Pros

- High throughput capacity systems available

- Automated operation minimizes labor

- Explosion protection features for safety

- Customization to handle bulk powder characteristics

- Energy efficient operation possible

- Validation and regulations compliance

- Sanitary designs meeting food/pharma standards

- Integrated controls for simple operation

- Advanced diagnostics and preventive maintenance

- Optional material contact surfaces like stainless steel

Cons

- High initial capital investment

- Significant installation costs

- Ongoing maintenance and parts replacement

- Complex control systems require trained staff

- Long equipment lead times – up to months

- Older designs have limited safety features

- Larger footprint than other processing methods

- Not ideal for small batches or frequent changeovers

- Limitations handling extremely fine or cohesive powders

The optimum equipment configuration depends on production variables, safety requirements, and budget. Work closely with suppliers to select the ideal iron powder handling equipment for your application.

Comparing Iron Powder Handling Equipment

Several types of equipment are commonly used for transporting and processing iron powder.

Pneumatic Conveying

- Uses air to convey powder through pipes

- High transfer rates possible

- Requires blowers and cyclones

- Risk of dust explosions in pipes

Mechanical Conveying

- Enclosed belt conveyors, bucket elevators

- No product contamination

- Limited vertical lift ability

- Prone to wear, require maintenance

Bin Activators

- Promote material flow from bins

- Rotating bins, vibrators, air pads

- Simple, low maintenance equipment

- Limited flow rate control

Feeders

- Volumetrically or gravimetrically meter powder

- Precise powder feeding for processes

- Many designs – screw, rotary valve, vibratory

- Rate matching critical for some applications

Size Reduction

- Hammer mills, impactors, grinders

- Achieve target particle sizes and distributions

- High energy consumption and wear

- Significant dust generation

Mixing

- Blend raw materials into homogeneous mixtures

- Ribbon blenders, rotary batch mixers

- Long blend times for large batches

- Difficult handling sticky blends

Drying

- Reduce moisture content using heaters

- Batch or continuous operation

- Energy intensive depending on type

- Risk of overheating sensitive powders

Evaluate options to select ideal equipment that provides required functionality, safety, and efficiency for your process. Pilot trials are recommended for large capital investments.

Iron Powder Equipment Maintenance Checklist

Regular maintenance is essential for iron powder equipment. Follow this maintenance checklist:

Daily Checks

- Inspect equipment for damage and leaks

- Verify instrumentation functioning

- Check dust collector differential pressure

- Confirm discharge devices not plugged

- Inspect structures and platforms

- Check belt alignment and tension

- Fastener inspections

- Test emergency stops

Weekly Checks

- Motor voltage and current

- Lubricate bearings and chains

- Inspect screens and filters – replace if needed

- Check belt wear

- Test explosion vents

- Inspect gaskets and seals

- Functional test automated valves

- Calibrate weighing devices

Monthly Checks

- Check drive alignment and couplings

- Inspect screw liners and replace

- Check foundation bolts

- Calibrate instruments

- Inspect chain elongation

- Verify belt scale accuracy

- Test pressure relief devices

Quarterly Checks

- Check shaft runouts

- Pulley and sprocket inspection

- Gearbox oil analysis

- Internal structural inspections

- Dust collector integrity testing

- Pipe and duct wall thickness

Follow all manufacturer recommended maintenance actions. Use checklists to ensure consistency. Maintain records in a Computerized Maintenance Management System (CMMS).

Iron Powder Equipment – Frequently Asked Questions

Q: What types of iron powder can be handled?

A: Most commercial grades and types of iron powder can be effectively handled including carbonyl, electrolytic, reduced, and atomized. Equipment can also process alloyed and insulated iron powders.

Q: How much iron powder can systems process per hour?

A: Production capacity ranges from hundreds of pounds per hour for small units to over 100 tons per hour for the largest continuous systems.

Q: What industries use iron powder handling equipment?

A: Major industries include powder metallurgy part manufacturing, powder coatings, food, pharmaceutical, cosmetic, and chemical processing.

Q: What safety features are incorporated?

A: Common safety features include inert gas blanketing, deflagration venting, explosion suppression systems, dust containment, and miscellaneous spark detection and fire protection.

Q: What degree of automation and control is possible?

A: Systems can range from simple manual operation to fully automated PLC-based control with advanced features like process optimization and predictive maintenance.

Q: How to determine correct equipment sizing?

A: The supplier will determine equipment sizes and production rates based on key parameters like bulk density, flowability, maximum lump size, and conveyance distance.

Q: What installation support do suppliers provide?

A: Suppliers provide complete installation manuals, drawings, technical support, and can contract installation and commissioning services by factory technicians.

Q: What maintenance is required?

A: Routine maintenance consists of inspections, lubrication, adjustments, part replacement, and housekeeping according to manufacturer schedules.

Q: How long is the typical equipment lifetime?

A: Well maintained equipment has an expected lifetime of 10-20 years. Rebuilds and upgrades can extend useful life further.

Q: What factors affect iron powder equipment pricing?

A: Key factors are capacity/throughput, control systems complexity, explosion protection, customization, material contacts, and certifications required.