Table of Contents

Toggleniobium tin powder is an intermetallic compound made from mixing niobium and tin that enables manufacturing of superconducting wires. Its unique properties under cryogenic conditions enable lossless electrical transmission for highly efficient magnets.

This article provides specifications, manufacturing method, applications, pricing and sourcing advisory on niobium tin superconducting wire powder.

Types and Composition of niobium tin powder

Niobium tin intermetallic powder for superconductor wire production meeting industrial standards will have a composition of:

| Element | Weight % |

|---|---|

| Niobium (Nb) | 24-26% |

| Tin (Sn) | 74-76% |

Key characteristics:

- Solid solution of Nb in beta-Sn matrix

- Cubic crystal structure

- silver-gray color and shiny metallic luster

- High purity levels

- Precisely controlled stoichiometry

Maintaining the exact Nb-Sn compound ratios during powder processing is critical to achieve superconducting properties in the final wire.

Manufacturing Process

- Start with high purity niobium and tin metals

- Convert to powder form by atomization or other means

- Precisely mix elemental niobium and tin powders

- Ball mill the blended powder to homogenize

- Sieve to control particulate sizes

- Apply binders/lubricants to aid wire drawing process

- Pack NbSn billets via cold isostatic pressing

- Extrude rods and draw into fine multifilament wires

- Stabilize superconducting matrix through heat treatment

Achieving uniform NbSn consistency, density and grain structure requires extensive process controls during powder production.

Physical Properties

NbSn has these nominal physical properties per ASTM standards:

| Property | Value | Unit |

|---|---|---|

| Density | 8.2 | g/cm3 |

| Melting point | 2163 | °C |

| Superconducting Transition Temperature | 18 | K |

| Critical Magnetic Field (Hc2) | 30 | T |

| Residual Resistivity Ratio (RRR) | >50+ |

- High Tc superconductor

- Brittle intermetallic compound

- Retains ductility for wire fabrication

- Superconductive under cryogenic use conditions (4K)

Precisely monitoring powder attributes minimizes defects in wire that degrade magnet performance.

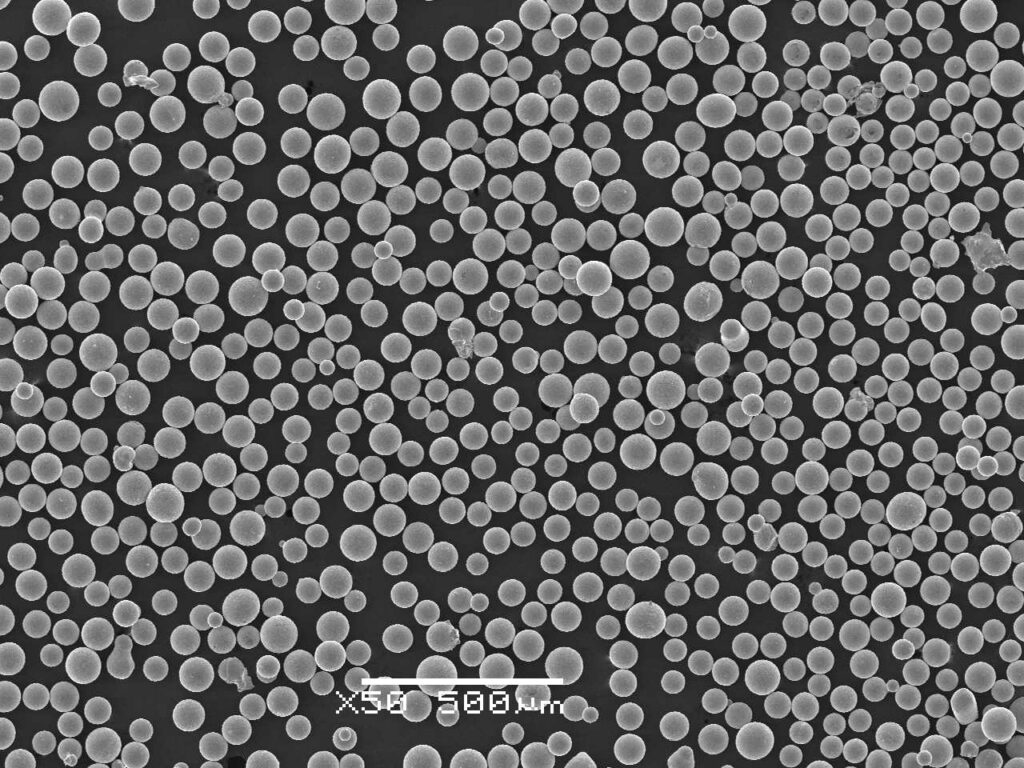

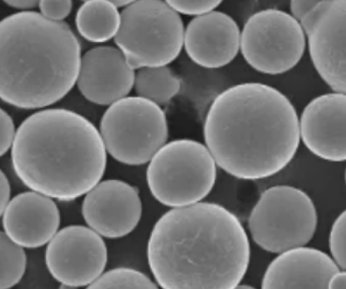

Microstructure

- Equiaxed grains

- Average particle sizes 1-50 microns

- Beta-tin matrix with Nb veins

- Porosity under 5%

- Chemically homogeneous

- Control oxygen/nitrogen below 20 ppm

Optimized microstructure achieved via atomization process controls enables effective wire fabrication and superconducting properties.

Purity Standards

Industrial grade niobium tin powder must meet minimum purity requirements:

| Impurity | Max weight ppm |

|---|---|

| Carbon (C) | 1500 |

| Oxygen (O) | 1500 |

| Nitrogen (N) | 80 |

| Hydrogen (H) | 15 |

| Nickel (Ni) | 150 |

| Iron (Fe) | 150 |

| Chromium (Cr) | 150 |

Higher purity levels used in research applications. Strict process controls during manufacturing minimize detrimental elements. Note contamination greatly impacts superconductor quality – keep handling precautions high.

Particle Size Distribution

Sieve analysis determines particulate size spread:

| Mesh | Microns | Min % | Max % |

|---|---|---|---|

| -635 | 20 | 0 | 10 |

| -500 | 25 | 0 | 30 |

| -400 | 38 | 25 | 65 |

| -325 | 45 | 30 | 75 |

| -270 | 53 | 15 | 50 |

| -200 | 75 | 0 | 15 |

Controlling particle size distribution promotes density and consistency during billet fabrication. Finer particles can degrade wire drawing performance. Frequent testing with sieve shakers tracks batch quality.

Typical Use Applications

- High field superconducting magnets

- NMR spectroscopy

- Medical MRI scanners

- Beam focusing magnets for particle accelerators

- Magnetohydrodynamic ship propulsion

- Experimental fusion reactors

- Superconducting energy storage coils

- High speed levitation transport

- Fault current limiters in electric grids

Precision NbSn powder enables manufacturing energy-efficient superconducting wire for various industrial and research magnet applications under cryogenic use conditions.

Industry Specifications

- ASTM B783 – Standard specification for niobium-tin superconductor wire

- IEC 61788-20 – Superconductivity standards for composite superconductors

- ISO 14850 – Determination of intermetallic compound content in Niobium-Tin superconductors

- Minimum 96% composite purity with prescribed Nb:Sn ratios

Powder suppliers must provide conformance certificates to standardized test methods and chemical assays for industrial qualification and magnet manufacturing use.

Packaging and Labeling

To prevent contamination and oxidation:

- 5 to 30 kg air-tight cans

- Vacuum sealed protective polymer bags

- Desiccant bags to absorb moisture

- Argon inert atmosphere

Each package is labeled per industrial norms with:

- Powder grade and lot number

- Date of manufacture

- Composition and purity test results

- Manufacturer name

- Net and gross weights

- Handling instructions

- Safety warnings

Properly packing preserves powder integrity. Inspect shipments carefully before use.

Pricing

| Grade | Purity | Price Range |

|---|---|---|

| Standard | 96-97% | $550 – $750 per kg |

| High purity | 99%+ | $1200+ per kg |

| Research | Ultra high purity 99.999% | $3000+ per kg |

Pricing depends on purity levels, prelim processing, order sizes and geographies. Contact vendors directly for up to date price quotes based on your target specifications.

High performance grade commands premium – pay for additional powder processing that ensures wire quality meeting application needs. Budget 15-25% cost of end magnet system.

Comparative Analysis

Evaluate niobium tin powder suppliers on these key aspects:

| Parameter | Details |

|---|---|

| Powder Purity | Maximize to prevent degraded wire; verify assay certs |

| Particle Size Control | Tight distribution for density, flowability |

| Elemental Homogeneity | Minimize variation across batches |

| Packaging Integrity | Prevent oxidation and moisture ingress |

| Lot Traceability | Facilitate defect root cause analysis |

| Sampling Protocols | Ensure representative batch analysis |

| Product Consistency | Validate wire fabrication suitability every run |

| Certifications | Review conformity to international specifications |

| Pricing | Compare transparent quotes; value vs premium grades |

Select powder partners focused on driving magnet performance metrics – field strength, current density and losses for your budget.

FAQs

Q: Is niobium tin powder toxic?

A: Niobium tin intermetallics have low bioavailability and are relatively non-toxic. But handling precautions should be taken to avoid inhaling powders or contact with skin or eyes as particulates may cause irritation. Use protective equipment.

Q: What is the difference between Nb-46.5wt%Ti vs Nb3Sn powder?

A: Niobium titanium powders like Nb-46.5wt%Ti exhibit lower temperature superconductivity and are used in niche applications, while Nb3Sn operating at 4K has higher magnetic field capabilities for broader use in research andmedical magnets.

Q: Does niobium tin powder need special storage?

A: Keep NbSn powder sealed in inert gas atmosphere away from moisture which degrades quality. Store long term between 10-30°C temperatures avoiding oxidation and hydride deterioration over time.

Q: What wire specifications match well with NbSn powder?

A: High performance NbSn F wires (bronze process multifilament with tin flux) properly optimize powder composite use achieving field strengths over 20Tesla at 4.5K or above temperatures.

Q: Where can I get niobium tin powder sample testing for qualification?

A: Leading global specialty metals suppliers have powder sample kits available specifically for superconducting wire manufacturers to evaluate powder compositions. Contact sales representatives to initiate material assessments.