Table of Contents

ToggleIntroduction

Welcome to a comprehensive guide on spherical tungsten powder, a fascinating material that finds applications in various industries due to its unique properties and characteristics. In this article, we will delve into the world of spherical tungsten powder, exploring its applications, manufacturing processes, advantages, challenges, safety considerations, and future research directions.

What is Spherical Tungsten Powder?

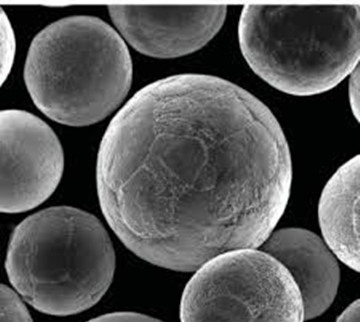

Spherical tungsten powder is a finely divided form of tungsten metal characterized by its spherical particle shape. It is produced through various atomization processes, resulting in a powder that exhibits excellent flowability and packing characteristics.

Properties and Characteristics of Spherical Tungsten Powder

Spherical tungsten powder boasts several essential properties that make it stand out as a versatile material in different applications. We will explore its density, particle size distribution, chemical purity, and other vital characteristics.

Applications of Spherical Tungsten Powder

The unique properties of spherical tungsten powder make it a preferred choice in various industries. Let’s explore its applications in powder metallurgy, thermal spray coatings, additive manufacturing, aerospace, defense, electronics, and semiconductors.

Powder Metallurgy

Powder metallurgy is one of the oldest and most significant applications of spherical tungsten powder. We’ll discuss how it contributes to the production of high-quality tungsten-based components.

Thermal Spray Coatings

The use of spherical tungsten powder in thermal spray coatings enhances the performance and durability of critical components. We’ll explore its role in this field.

Additive Manufacturing

Additive manufacturing, also known as 3D printing, has seen substantial advancements with the incorporation of spherical tungsten powder. We’ll uncover the exciting possibilities it offers.

Aerospace and Defense Industries

The aerospace and defense sectors benefit significantly from the unique properties of spherical tungsten powder. We’ll explore how it contributes to these industries.

Electronics and Semiconductors

In the electronics and semiconductor industries, spherical tungsten powder plays a crucial role. We’ll delve into its applications and contributions in this area.

Advantages of Using Spherical Tungsten Powder

The use of spherical tungsten powder offers numerous advantages over other forms of tungsten powder. We’ll discuss how it improves flowability, packing density, reduces porosity, and ensures uniform coating thickness.

Improved Flowability

The spherical shape of tungsten powder enhances its flowability, making it easier to handle and process.

Enhanced Packing Density

Spherical tungsten powder enables higher packing densities, leading to more efficient use of the material.

Reduced Porosity

The reduced porosity of components made from spherical tungsten powder results in enhanced mechanical properties.

Uniform Coating Thickness

In thermal spray coatings and additive manufacturing, the use of spherical tungsten powder ensures uniform coating thickness for consistent results.

Manufacturing Process of Spherical Tungsten Powder

The production of spherical tungsten powder involves sophisticated atomization processes. We’ll explore gas atomization, plasma atomization, and centrifugal atomization methods in detail.

Gas Atomization

Gas atomization is a widely used technique for producing spherical tungsten powder. We’ll explain the process and its advantages.

Plasma Atomization

Plasma atomization is another advanced method for manufacturing spherical tungsten powder. We’ll discuss its benefits and applications.

Centrifugal Atomization

The centrifugal atomization process offers unique advantages in producing spherical tungsten powder. We’ll explore its working principles and outcomes.

Quality Control and Testing

Ensuring the quality and consistency of spherical tungsten powder is crucial. We’ll discuss the various testing and quality control measures employed during production.

Particle Size Analysis

Particle size analysis is a vital aspect of quality control, and we’ll explain its significance in evaluating spherical tungsten powder.

Chemical Purity Assessment

The chemical purity of tungsten powder influences its performance. We’ll explore the methods used to assess and maintain purity levels.

Morphology and Surface Inspection

The morphology and surface characteristics of spherical tungsten powder are critical factors in its applications. We’ll discuss inspection techniques.

Flowability and Packing Characteristics

Measuring flowability and packing characteristics ensures consistent performance in various applications. We’ll explore the testing methodologies.

Market Trends and Outlook

The demand for spherical tungsten powder is on the rise, driven by various factors. We’ll discuss market trends and the future outlook for this remarkable material.

Growing Demand in Electronics Sector

The electronics industry is witnessing an increased demand for spherical tungsten powder due to its unique properties. As technology advances, electronic devices become more compact and sophisticated, requiring materials that can meet stringent performance demands. Spherical tungsten powder’s excellent flowability and high packing density make it an ideal choice for manufacturing miniaturized electronic components.

Advancements in Additive Manufacturing

Additive manufacturing has revolutionized the way we produce complex and customized parts. Spherical tungsten powder plays a significant role in this area, as it enables the fabrication of high-strength and heat-resistant components for aerospace, automotive, and medical applications. As the additive manufacturing industry continues to grow, the demand for spherical tungsten powder is expected to rise further.

Increasing Applications in Aerospace Industry

The aerospace sector demands materials that can withstand extreme conditions and offer high performance. Spherical tungsten powder’s remarkable properties make it a valuable asset in the aerospace industry. From manufacturing rocket engine components to advanced turbine blades, spherical tungsten powder contributes to the production of cutting-edge aerospace technologies.

Challenges and Limitations

While spherical tungsten powder offers numerous benefits, it also faces some challenges and limitations that need to be addressed.

Cost of Production

Producing spherical tungsten powder through advanced atomization processes can be expensive, which affects the final cost of the material. Manufacturers are continuously striving to optimize production techniques and reduce costs to make it more accessible for various applications.

Environmental Concerns

The manufacturing process of spherical tungsten powder involves the use of energy-intensive technologies and may generate waste products. Efforts are being made to implement sustainable practices and minimize the environmental impact associated with its production.

Technological Constraints

While atomization processes have advanced significantly, there are still limitations in achieving precise control over particle size distribution and morphology. Ongoing research focuses on overcoming these constraints to enhance the material’s performance further.

Safety Considerations

Safety is paramount when handling spherical tungsten powder, as it is a fine and dense material that requires careful management.

Handling and Storage

Proper handling and storage procedures are essential to prevent accidents and exposure to the material. Manufacturers and end-users should follow guidelines and best practices to ensure safety.

Personal Protective Equipment (PPE)

Workers involved in handling spherical tungsten powder must use appropriate personal protective equipment, such as gloves, masks, and safety glasses, to minimize the risk of contact and inhalation.

Future Innovations and Research Areas

The fascinating properties of spherical tungsten powder open up new possibilities for future innovations and research.

Nanoscale Tungsten Powder

Research is ongoing to produce nanoscale spherical tungsten powder, which could lead to even more advanced applications in nanotechnology and biomedical fields.

Composite Powder Development

Combining spherical tungsten powder with other materials may result in novel composite powders that exhibit unique properties and functionalities.

Conclusion

In conclusion, spherical tungsten powder is a remarkable material with a wide range of applications across various industries. Its unique properties, including improved flowability, enhanced packing density, and uniform coating thickness, make it an attractive choice for critical components. As technology continues to advance, spherical tungsten powder is expected to play a vital role in shaping the future of electronics, aerospace, and additive manufacturing industries.

FAQs

What are the main applications of spherical tungsten powder?

Spherical tungsten powder finds applications in powder metallurgy, thermal spray coatings, additive manufacturing, aerospace, defense, electronics, and semiconductors.

How is spherical tungsten powder manufactured?

Spherical tungsten powder is primarily produced through gas atomization, plasma atomization, and centrifugal atomization processes.

What are the advantages of using spherical tungsten powder in additive manufacturing?

Spherical tungsten powder offers improved flowability, enhanced packing density, reduced porosity, and uniform coating thickness, resulting in high-performance components.

Are there any safety precautions to consider when handling spherical tungsten powder?

Yes, handling spherical tungsten powder requires appropriate safety measures, including the use of personal protective equipment and proper storage practices.

What are the future research directions for spherical tungsten powder?

Future research in spherical tungsten powder may focus on nanoscale powder development and composite powder formulations to expand its applications further.