TiZrNb Powders┃Medium Entropy Alloy (MEA) Powder

A simple equiatomic Ti-Zr-Nb medium entropy alloy (MEA) powder designed for biocompatible materials, closer to that of human bone than Ti6Al4V, was prepared by Plasma Rotating Electrode Process (PREP) method. Furthermore, its electrochemical behavior exhibited that its corrosion resistance were equivalent to that of Ti6Al4V. So it is more attractive for biomedical application because medium-entropy or high-entropy alloys (MEAs and HEAs), which consist of three to five elements in nearly equiatomic composition, can maintain the main advantages of beta titanium alloys and simultaneously activate additional strengthening mechanisms, like solid solution hardening or TRIP/TWIP effects.

We conducted some research on the preparation of customized Ti-Zr-Nb alloy powder using plasma rotating electrode equipment. And we also did some studies on the porosity and oxygen content characteristics of the powder using scanning electron microscopy and gas analyzer. It showed TiZrNb powderproduced by PREP has uniform composition, high purity, high sphericity, adjustable particle size according tothe preparation parameters andless hollow powder.

Prepared by our small-scale PREP system SLPA-D30 (Fig 1), The powder yield of TiZrNb can reach 18.5% at 15-53 microns, 50.5% at 53-106 microns, 11.2% at 106-150 microns, and above 150 microns for the rest. There are almost no powders below 15 microns.

Fig. 1 Truer SLPA-D30 PREP System

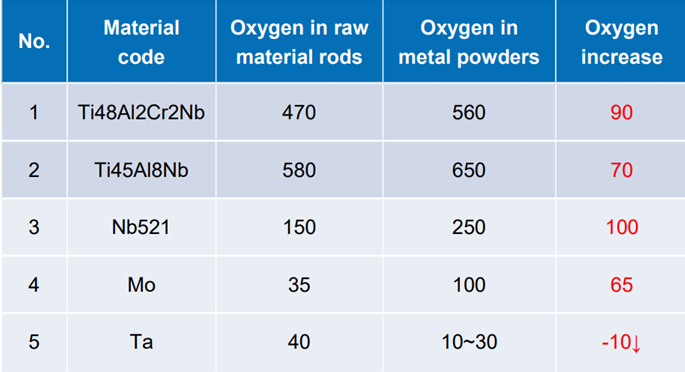

Oxygen percentage of TiZrNb powder produced by PREP system gradually decreases as the powder particle size increases (Table 1). When the powder particle size is 15-53 microns, oxygen wt% is 307ppm and when 45-105 microns, it can reach 235ppm.

| C.S,O& N Content(wt%) | ||||

| PSD | C | S | O | N |

| 15-53um | 0.006419 | 0.000096 | 0.030721 | 0.002165 |

| 45-105um | 0.005472 | 0.000154 | 0.023560 | 0.001398 |

| Standard: GB/T 14265 | ||||

Table 1 Carbon, Sulfur, Oxygen & Nitrogen Analysis of TiZrNb powder

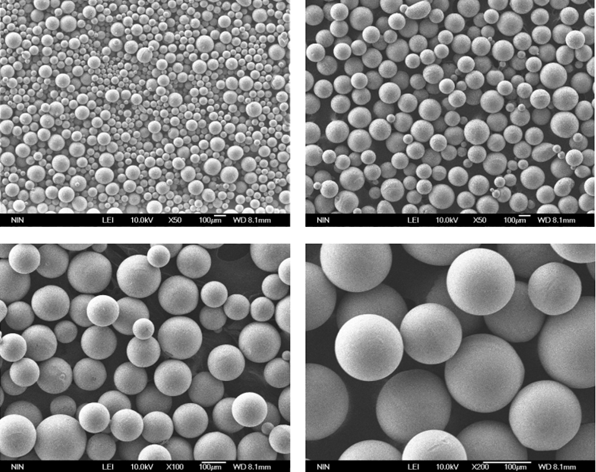

Powder morphology analysis of TiZrNb powder by SEM (Fig. 2) shows that most powders are spherical with a sphericitygreater than 95%. This is determined by the mechanism of spherical powder formation in the plasma rotating electrode atomization method. After the rotating anode alloy rod melts, a liquid film area is formed at the edge of the rod. The alloy liquid in this area is randomly splashed out under centrifugal force, forming small individual droplets. During flight, due to the effect of surface tension, it gradually spheroidizes and solidifies to form high sphericity powders.

Fig. 2 Morphology of TiZrNb powder by SEM

In addition to the production of customizedTiZrNb alloy powders, we also can customize some special high-temperature alloys (such as CMSX-4), stainless steel (such as 1.4091), refractory metals & their alloys (W, Mo, Ta, Nb), high entropy alloys (AlCoCrFeNi, FeCrMnCoNi, TiNbHf, TiZrNbMoHf, etc.), precious metals & its alloys (Ag) by both PREP and GA methods.

Below is oxygen characteristics of some other powders by our PREP system for your information.