Table of Contents

ToggleTungsten powder is a pure elemental powder form of tungsten metal used across industrial applications requiring high density, strength, and heat resistance properties. This guide provides an overview of tungsten powder composition, production methods, applications, tungsten powder supplier, pricing, and comparisons.

Introduction to tungsten powder supplier

Tungsten powder is composed of microscopic particles of relatively pure elemental tungsten metal. Key properties of tungsten making it suitable for powder metallurgy applications are:

- Extremely high density – similar to gold

- Highest melting point of all metals

- Low coefficient of thermal expansion

- High thermal and electrical conductivity

- Resistance to corrosion and acids

- Biocompatibility and non-toxicity

With a density almost 20% higher than lead, tungsten balances performance across strength, conductivity and thermal properties – ideal for use as powder particles.

Tungsten Powder Characteristics

| Attribute | Details |

|---|---|

| Composition | 99.9% Pure Tungsten |

| Color | Dark gray with metallic lustre |

| Crystal structure | Cubic |

| Density | 19.3 g/cm3 |

| Melting Point | 6170°F (3422°C) |

| Mohs hardness | 7-7.5 |

| Thermal conductivity | 163 W/m·K |

| Electrical resistivity | 5.5 μΩ·cm |

These intrinsic material properties enable niche applications for tungsten powder across electronics, alloys, weighting, heating, and more.

Manufacturing Methods

Tungsten powder is produced from tungsten ore concentrates using advanced metallurgy techniques:

1. Ammonium Paratungstate Processing

- Most common production method

- Involves acid extraction, precipitation, drying, hydrogen reduction

- Creates high purity fine powders

2. Mechanical Milling

- Milling tungsten metal into fine particles

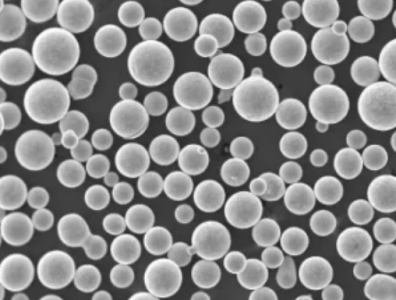

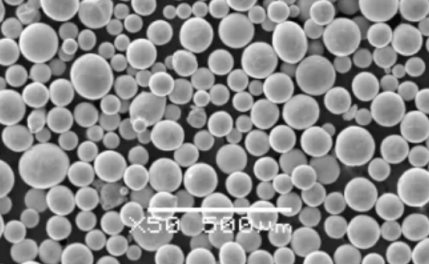

- Tends to produce irregular shapes

- Lower cost but wide size distribution

3. Thermochemical Processing

- Vapor phase conversion of tungsten halides

- Results in very high purity spherical powders

- Small scale specialized production

Manufacturing method determines powder particle size distribution, shape, tap density and surface chemistry – which dictate applicability.

Applications of Tungsten Powder

Unique high density properties of tungsten powder make it suitable for:

Table: Tungsten Powder Applications

| طلب | Description |

|---|---|

| Counterweights | High density balance weights for vibration sensitive equipment |

| Radiation Shielding | Tungsten alloys used as gamma ray shielding material |

| Ballast | Alternative to lead weights in yacht keels for stability |

| Rotating Equipment | Tungsten heavy metal used in gyroscopes and centrifuges |

| Thermal Management | Heat sinks made using tungsten due to high thermal conductivity |

| Carrier Powders | Binder matrix for catalysts requiring chemical resistance |

| Electrical Contacts | Tungsten-silver alloys used in switches and relays |

| 3D Printing Powders | High density tungsten used in additive manufacturing |

Tungsten’s suitability for high temperature thermionic emission also makes it useful for electron emitters in electric welding and vacuum tube equipment as a powder cold-pressed into electrodes.

Specifications

Tungsten powder for industrial and commercial use is categorized by:

Table: Tungsten Powder Specifications

| Parameter | Details |

|---|---|

| Purity Grades | 99.9%, 99.95%, 99.99% pure tungsten |

| Particle Size | 0.5 to 150 microns |

| Morphology | Irregular, spherical |

| Tap Density | 2 to 12 g/cm3 |

| Surface Area | 0.5 to 10 m2/g |

| Appearance | Dark gray powder |

| Packaging | 1lb bottles to 55 lb pails |

Other application-specific technical specifications may include thermal expansion coefficients, compressibility, hydrogen content, oxygen analysis, and green strength values.

Where to Buy Tungsten Powder

Tungsten being relatively rare is available from specialized manufacturers and suppliers:

Table: tungsten powder supplier

| Supplier | Location | Product Grades |

|---|---|---|

| Midwest Tungsten Service | USA | Tungsten alloys, pure tungsten |

| Buffalo Tungsten | USA | Powders, rods, wires |

| Tungsten Heavy Powder | China | 99.995% (5N) purity powder |

| Xiamen Tungsten | China | 5N, 5N5, 6N powder |

| Beck Alloys | UK | Elemental and alloyed tungsten |

| HC Starck | Germany | High purity refractory metals |

| Nanjing Tungsten | China | Pure tungsten powder |

| Japan New Metal | Japan | Nano to coarse tungsten powder |

As tungsten mining and refining both require specialized processing, economical availability comes primarily from China followed by Russia, Canada, Bolivia and Portugal. Established manufacturers provide different purity levels suitable for medical, industrial and research applications.

Tungsten Powder Price

Being relatively rare, tungsten powder is more expensive than common metals – priced between $50 to $500 per kilogram based on:

Table: Tungsten Powder Pricing

| Factor | Description |

|---|---|

| Purity | 99.9% costs ~$50/kg; 99.999% costs ~$500/kg |

| Particle Size | Nano powder is pricier than micron sizes |

| Quantity | Bulk orders of 25kg+ enables volume discounts |

| Manufacturing Method | Chemical vs mechanical process |

| Grain Shape | Spherical powder carries a premium |

Exact pricing varies across time and geographies – contact trusted suppliers to request latest quote with shipping charges. Consider quantity discounts above 25 kgs for cost savings on high purity powders.

How to Select Tungsten Powder

Factors guiding tungsten powder selection:

Table: Tungsten Powder Selection Criteria

| Parameter | Description |

|---|---|

| Application Requirements | Density needs, operating temperatures, loads, expected lifetime, approvals required |

| Specification Match | Particle size, purity level, tap density, surface area etc |

| Supplier Qualifications | Experience, quality systems and control practices |

| Sampling | Get powder samples to test suitability |

| Total Cost | Compare pricing from shortlisted suppliers including logistics |

| Technical Support | Evaluate supplier design support vs just sales |

| Certifications | Review material test reports (MTRs) for peace of mind |

Work with qualified suppliers to procure your optimal tungsten powder grade cost-effectively based on intended production method and performance criteria.

Pros and Cons of Using Tungsten Powder

Table: Advantages and Disadvantages of Tungsten Powder

| Pros | Cons |

|---|---|

| Extremely high density | Expensive compared to common metals |

| Highest melting point of metals | Limited global supply and availability |

| Thermal/electrical conductivity | Requires careful handling given high density |

| Alloy flexibility | Considered hazardous shipping material |

| Biocompatible for medical uses | Need for experienced suppliers |

| Enables performance enhancements | Potential for counterfeit products |

For specialty applications needing high density or thermal conductivity, tungsten powder provides significant benefits. Cost and availability concerns require careful management.

Frequently Asked Questions

How is tungsten powder safely handled and stored?

Follow safety datasheets – wear personal protective equipment, avoid inhalation using respirators, handle packages carefully given heavy weight. Store sealed containers properly labeled away from moisture and extremes of temperature in cool, inert environments.

What industries use tungsten powder the most?

Industries taking advantage of tungsten’s special properties include aerospace, radiation shielding, automotive, batteries, and medical plus emerging areas like additive manufacturing/3D printing.

Does tungsten powder require special shipping or export controls?

As tungsten qualifies as a dual-use product, exporting may require licenses. Classified as dangerous goods during shipping, it needs competent handlers aware of density and combustion hazards following applicable regulations.

What substitutes exist for tungsten powder?

Few alternative materials match tungsten’s thermal stability and density. Depleted uranium approaches density but introduces radioactivity concerns. Lead is cheaper for some weighing applications but toxic while lacking strength and temperature performance.

What typical size is tungsten powder used for 3D printing?

Particle size distribution averaging 20 microns works well for powder bed fusion 3D printing processes enabling complex, high density metal part production – used alone or blended with other powders.

Conclusion

Offering extraordinary density paired with temperature resistance, tungsten powder suits special performance requirements despite higher costs. Carefully selecting specifications like particle size and purity along with reputable suppliers enables tapping benefits across electronics, radiation shielding and modern metal additive manufacturing. As an impactful pure element, tungsten powder facilitates pushing application boundaries when engineered creatively.