Table of Contents

ToggleCobalt tungsten powder is an important material with growing applications across industries like aerospace, automotive, medical, and electronics. This powder mixture combines the high strength, hardness and thermal properties of tungsten with the unique magnetic and catalytic qualities of cobalt.

In this comprehensive guide, we will cover everything you need to know about cobalt tungsten powder, including:

Overview of Cobalt Tungsten Powder

Cobalt tungsten powder, also known as cemented tungsten carbide cobalt (WC-Co), refers to a composite material made by mixing particles of tungsten carbide (WC) with cobalt as a binder.

Key properties:

- Extreme hardness and high strength

- Excellent wear resistance

- Good thermal conductivity

- High temperature strength

- Low thermal expansion

- Good corrosion resistance

- Cobalt provides toughness and shock resistance

Typical composition:

- Tungsten carbide: 80-97%

- Cobalt: 3-20%

Particle sizes:

- Micrograin: 1-10 microns

- Submicron: 0.1-1 micron

- Nanoscale: Under 100 nm

Finer particle sizes result in increased hardness and strength. Nanoscale cobalt tungsten is an advanced form with enhanced properties.

Production process:

Cobalt tungsten powder is produced via liquid phase sintering of tungsten carbide and cobalt particles at 1300-1600°C. The cobalt melts and wets the tungsten carbide particles, binding them together during cooling. This forms a hard composite material.

Common applications:

- Cutting tools

- Dies and tooling

- Drill bits

- Wear parts

- Structural components

- Medical implants

- Electrical contacts

- Thermal spray coatings

Cobalt tungsten offers an optimal balance of hardness, toughness and thermo-mechanical properties for these demanding applications.

Types of Cobalt Tungsten Powder

There are two main types of cobalt tungsten powder categorized by their production method:

Sintered Cobalt Tungsten Powder

This conventional powder is produced by milling sintered cobalt tungsten chunks/scrap into fine powders.

Characteristics:

- Irregular shaped particles with wide size distribution

- Coarse powder in micron sizes

- Lower powder purity/density

- Limited flexibility in composition

Applications:

- Cutting tools

- Wear parts

- Low cost uses

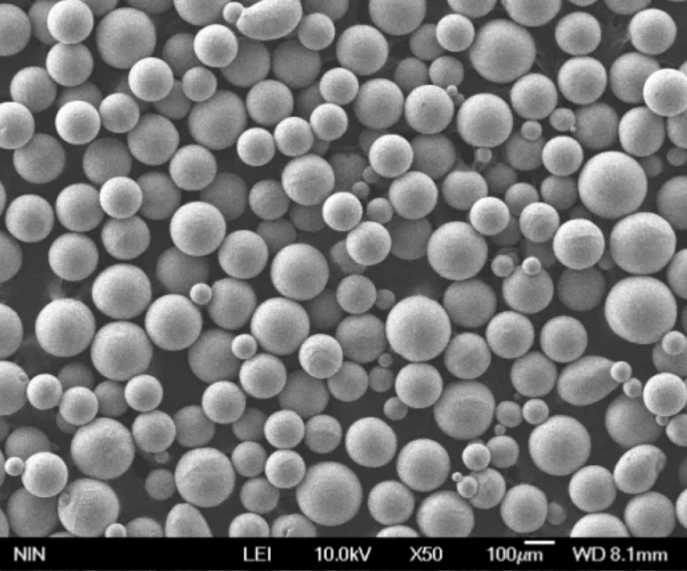

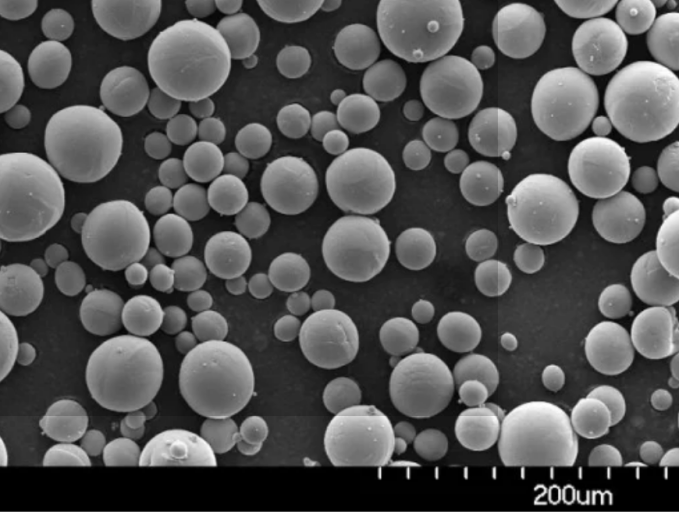

Fused and Crushed Cobalt Tungsten Powder

Produced by melting, rapidly solidifying and crushing cobalt tungsten alloy into fine powder.

Characteristics:

- Spherical morphology with tight size control

- Ultrafine powder down to nanoscale

- High purity/density

- Flexibility in cobalt content

Applications:

- Thermal spray coatings

- Metal injection molding

- Additive manufacturing

- Diamond tools

- Nanostructured cemented carbides

The fine uniform particles provide superior properties and enable advanced applications.

Properties of Cobalt Tungsten Powder

The unique combination of tungsten carbide and cobalt imparts exceptional properties to cobalt tungsten powder:

| Property | Function |

|---|---|

| Extreme hardness | Resists wear and abrasion |

| High strength | Withstands mechanical loads without deformation |

| Toughness | Resistance to fracture and impact |

| Wear resistance | Long service life in abrasive conditions |

| Corrosion resistance | Performs reliably in harsh environments |

| Thermal conductivity | Dissipates heat effectively |

| Oxidation resistance | Handles high temperatures without oxidation |

| Temperature stability | Dimensional stability under thermal cycling |

The properties make cobalt tungsten suitable for:

- Cutting, drilling and machining of tough alloys

- High temperature furnace parts

- Friction, sealing and bearing applications

- Tools, dies and wear components

- Medical implants and dental fillings

Fine cobalt tungsten powders enhance properties for next-gen applications.

Applications and Uses of Cobalt Tungsten Powder

Cobalt tungsten powder and its composites are utilized across a diverse range of industries and applications:

| Industry | Applications |

|---|---|

| Metalworking | Cutting tools, saw blades, milling inserts, drill bits, taps, reamers, wire drawing dies |

| Oil & gas | Downhole tools, drill bits, tool joints, valves, seals |

| Mining | Crushers, pulverizers, grinders, excavator teeth |

| Automotive | Dies, engine parts, bearings, valves, turbocharger components |

| Aerospace | Turbine blades, rocket nozzles, landing gear parts |

| Electronics | Lead frames, contacts, connectors, heat sinks |

| Medical | Dental tools, prosthetics, implants, radiation shielding |

Other applications include wear parts, tooling, satellites, thermal spray coatings and more.

The unique properties of cobalt tungsten powder make it indispensable for these critical applications across industries.

Cobalt Tungsten Powder Specifications

Cobalt tungsten powder can be customized as per application requirements with the following specifications:

| Parameter | Options |

|---|---|

| Particle size | Micrograin, submicron, nano |

| Grain size | Ultrafine, nanocrystalline |

| Carbide content | 80-97% WC |

| Binder content | 3-20% cobalt |

| Carbon content | Low carbon, medium carbon, high carbon |

| Porosity | Fully dense, low porosity |

| Morphology | Angular, rounded/spherical |

| Purity | Up to 99.9% |

Typical size ranges:

- Micrograin: 1-15 microns

- Submicron: 0.2-1 microns

- Nanoscale: 10-200 nm

Compositions:

- WC-6Co, WC-10Co, WC-12Co etc.

Grades:

C1, C2, C3 etc. based on cobalt content

Specifying the right cobalt tungsten grade and particle size is critical for optimizing performance.

Design and Engineering Standards

Cobalt tungsten powder products and composites must meet various critical standards for quality assurance:

- ISO 4499 – Cemented tungsten carbides

- ASTM B777 – Standard specification for tungsten base powder

- ASTM E1580 – Wear testing with microabrasion test rig

- ISO 1832 – Hardmetals – Determination of transverse rupture strength

- ASTM B406 – Analysis of tungsten carbide powders

- ISO 4507 – Hardmetals – Vickers hardness testing

- ASTM E112 – Determining average grain size

Compliance with these standards ensures optimal and consistent performance.

Suppliers of Cobalt Tungsten Powder

There are many reputable cobalt tungsten powder manufacturers across the globe:

| Company | Location | Products | Pricing |

|---|---|---|---|

| Sandvik | Sweden | Micrograin and submicron WC-Co | $xx to $xxx/kg |

| Kennametal | USA | Nanoscale and micro WC-Co | $xx to $xxx/kg |

| H.C. Starck | Germany | Range of carbide grades | $xx to $xxx/kg |

| Japan New Metals | Japan | Spherical WC-Co powder | $xx to $xxx/kg |

Other major suppliers:

- Vollmer

- Ceratizit

- Mitsubishi Materials

- Korea Tungsten

Pricing considerations:

- Powder size and morphology

- Purity levels

- Composition and carbon content

- Purchase quantity and bulk pricing

Work with qualified suppliers who offer the right powder specifications for your specific application needs.

How to Choose a Cobalt Tungsten Powder Supplier

Here are key factors to consider when selecting a cobalt tungsten powder supplier:

- Technical expertise in powder metallurgy of cemented carbides

- Powder customization capabilities for particle size, shape, purity etc.

- Stringent quality control and testing procedures

- Global certifications like ISO 9001

- R&D competence for novel compositions and grades

- Reasonable pricing for quality products

- Production capacity to meet demand

- Inventory availability for quick delivery

- Strong customer service and technical support

Prioritize suppliers who can provide in-depth technical advice and optimize powders for your particular manufacturing processes and end-use applications.

Installing and Operating Cobalt Tungsten Powder Equipment

Here are some guidelines on installing and operating equipment for cobalt tungsten powder processing:

| Equipment | Installation Tips | Operation/Maintenance |

|---|---|---|

| Ball mill | Level foundation, tighten fasteners, test run | Control speed, cooling water flow, media charge; clean regularly |

| Spray dryer | Level ground, utilities, exhaust piping | Monitor inlet and outlet temps; check cyclone and scrubber |

| Sintering furnace | Power supply, water cooling, ventilation | Control heating/cooling rate; change thermocouples |

| Mixer | Anchor securely | Do not overmix; check torque; replace worn blades |

| Granulator | Level rigid base | Sharpen screen; replace hammers; lubricate; check particle size |

Safety measures:

- Use proper PPE – respirator, gloves, goggles

- Install dust collection systems

- Ground all electrical equipment

- Use spark-resistant tools

- Follow lockout/tagout procedures

Adhering to manufacturer operating procedures and preventive maintenance is critical for maximizing equipment life, performance and safety.

How to Choose a Cobalt Tungsten Powder Equipment Manufacturer

Choosing reputable equipment manufacturers is vital for cost-effective cobalt tungsten powder production. Considerations when selecting include:

| Parameter | Preferences |

|---|---|

| Technical expertise | Specific experience in tungsten carbide powder equipment |

| Customization | Ability to tailor designs to your needs |

| Proven designs | Field-tested reliability |

| Automation features | For productivity and consistency |

| Production throughput | Matches your volume needs |

| Easy maintenance | For convenient upkeep |

| Operating costs | Reasonable power/utility usage |

| Control system | User-friendly interface |

| Safety systems | Interlocks, alarms, sensors |

| Documentation | Manuals, training, certifications |

| Warranty and support | Installation help, maintenance |

Look for advanced automated equipment with safety mechanisms, robust controls and real-time monitoring to minimize issues and downtime. Partnership with reputable manufacturers ensures a smoother powder production process.

Pros and Cons of Cobalt Tungsten Powder

Advantages

- Extreme hardness and wear resistance

- High strength and temperature stability

- Good toughness despite brittleness

- Excellent thermal conductivity

- Resists corrosion and oxidation

- Retains stiffness and cutting edge at high temperatures

- Improves fatigue strength and fracture toughness

- Allows smaller/thinner component designs

Limitations

- Relatively high cost

- Reactivity with pure iron, nickel and titanium

- Sensitive to stress concentrators and impact loads

- Brittle with limited plasticity

- Challenging to machine in fully sintered state

- Not suitable for high magnetic permeability

- Requires diamond tools for machining

- Powder form poses dust explosion risk

Understanding both benefits and limitations aids selection for specific applications.

Comparing Cobalt Tungsten Powder to Alternatives

VS Tungsten Carbide

- Similar hardness and wear resistance

- Less toughness without cobalt binder

- Harder to shape and machine

- More difficult to sinter without cobalt

VS Tungsten Heavy Alloy

- Higher hardness and strength

- Better high temperature properties

- More wear and corrosion resistant

- More difficult to machine

VS Cemented Titanium Carbide

- Lower hardness but greater toughness

- Withstands higher temperatures

- Less dense and heavy

- More thermally and electrically conductive

- Higher cost

VS Stainless Steels

- Much greater hardness and wear resistance

- Maintains strength at higher temperatures

- Lower fracture toughness

- Higher density adds component weight

- More difficult to machine

Cobalt tungsten offers an optimal balance of properties for tooling, machining, mining and other specialized applications.

Future Outlook

Demand for cobalt tungsten powder is projected to grow at 7%+ CAGR over the next 5 years, driven by:

- Expanding tooling, metalworking and mining sectors

- Rising need for wear and heat resistant materials

- Growth in precision manufacturing

- Adoption of metal 3D printing techniques like binder jetting, DED etc.

- Developments in nanostructured grades

Key trends shaping the future of cobalt tungsten powder include:

- New high-speed steel and alloy alternatives

- Shift from micrograin to submicron and nanoscale powder

- Declining cobalt content for cost and supply chain reasons

- Recycling and reuse of tungsten carbide scrap

- Consolidation among major powder producers

- Automation in powder processing

With rising demand from high-performance applications, cobalt tungsten powder innovation and product development will continue evolving.

FAQ

Q: How is cobalt tungsten powder made?

A: It is produced via liquid phase sintering where cobalt particles melt and bind tungsten carbide particles together during heating and cooling. Alternative methods include fused, rapidly solidified powders.

Q: What is cemented carbide?

A: Cemented carbides like cobalt tungsten are composite materials where carbide particles are cemented together by a binding metal matrix like cobalt.

Q: What are the main advantages of cobalt tungsten powder?

A: Extreme hardness and wear resistance, high strength even at elevated temperatures, good thermal conductivity and resistance to corrosion/oxidation.

Q: What is nanostructured cobalt tungsten powder?

A: Ultrafine cobalt tungsten powder with nanoscale grains that provide enhanced mechanical properties. Particle sizes are under 100 nm.

Q: What industries use cobalt tungsten powder?

A: Major industries include metalworking, mining, oil and gas, aerospace, automotive, construction, electronics and medical devices.

Q: Is cobalt tungsten powder toxic?

A: Cobalt particles may cause irritation and sensitization. Proper PPE should be used when handling the powder.

Q: Is cobalt tungsten powder flammable or explosive?

A: Like many fine metal powders, it can pose dust explosion risks if not handled properly. Precautions are required.

Q: How should cobalt tungsten powder be stored?

A: In sealed containers in a dry, cool environment to prevent contamination and minimize oxidation or other chemical reactions.

Q: Does cobalt tungsten powder degrade over time?

A: If stored properly, the powder remains relatively stable. However, contamination or absorption of moisture can negatively impact properties.

Q: What is the difference between sintered and fused cobalt tungsten powder?

A: Sintered powder is made by milling chunks and has irregular shapes, while fused powder is made by melting and crushing for spherical morphology.

Q: What are common cobalt tungsten powder compositions?

A: Typical compositions are 80-97% tungsten carbide particles with 3-20% cobalt binder, such as WC-6%Co or WC-10%Co.